A while back, a German company that provides gas contacted Easy-Laser GmbH to participate in the troubleshooting of a machine that showed high vibrations levels. The machine was a geared compressor supplying nitrogen gas for the process. As part of the investigation, the compressor owner asked us to provide thermal compensation values for the alignment.

We got access to the report from the last shaft alignment job, where we could see that thermal compensation was applied.

Our plan for this investigation was to start by checking the shaft alignment status in cold conditions when the machine was standing still, in a non-operating state. And the results from this shaft alignment check revealed that the machines were misaligned more than twice the amount of the specified thermal compensation value in the vertical position.

We then installed laser sensors on the motor and the compressor to perform what is called a dynamic measurement (this is done using special brackets (see illustration below) and the alignment program EasyTrend).

We started the compressor and began to measure its dynamic movements. First, we performed a dynamic measurement until the machines reached operating temperature. Then we turned the machines off and performed shaft alignment verification in hot condition. Afterward, we mounted the sensors back on the machines again and measured the movement from hot to cold conditions.

We basically performed 4 measurements:

- Shaft alignment verification in Cold condition.

- Dynamic measurement from Cold to Running.

- Shaft alignment in Hot condition.

- Dynamic measurement from Hot to Cold condition.

The results:

The shaft alignment made during Cold condition revealed that thermal compensation values had been inserted into the alignment protocol, but they were more than doubled! A wrong interpretation of the compensation values or other mistakes must have occurred when the machines were aligned in the past.

The dynamic measurement from Cold to Running conditions revealed that the compressor movement in the vertical position, due to thermal expansion, was exactly the same as the specified thermal compensation value provided by the compressor owner. But, since that value was doubled, the compressor was heavily misaligned in the vertical direction. To our surprise, we found out that the compressor moved 1,3 mm in the horizontal position, which nobody expected. Horizontal misalignment of 1,3 mm is very severe.

The dynamic measurement from Hot to Cold conditions confirmed the values and direction of the movement while the compressor was cooling down.

Conclusion:

Do not assume that the calculated value for thermal compensation is correct and the machines are compensated for it correctly. Instead, measure your machines, check the alignment conditions, and verify.

Watch our Shaft Alignment Know-How: Thermal Growth video to learn the importance of accounting for thermal growth on rotating equipment!

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

by Diana Pereda

Not too long ago, I was called out to balance a supply fan on an air handler at the local zoo. I arrived on site and immediately noticed the heavy vibration coming from the air handler. I collected some vibration readings, shut the machine down, and locked it out. After looking through the vibration data and some visual inspection, I was able to rule out unbalance as the primary source of the vibration. The motor and fan bases on this belt-driven machine were in rough shape: loose and missing hardware, isolators worn and out of adjustment, and machine mounted to a weak foundation. These issues certainly made the vibration worse and needed to be addressed, but they were not the source of the vibration.

After performing a number of tests and checks, I found that the vibration was caused by a combination of sheave misalignment and an overly tensioned belt. After speaking with the customer, I found out that the belt and sheaves had just been installed the day before! Unfortunately, many millwrights and mechanics fail to have the training, tooling, or desire to properly align and tension a belt-driven machine. Taking the time to understand how and why to perform sheave alignment and how to properly tension a belt drive can save thousands on repair costs, increased efficiency, and unscheduled downtime. In addition, reliability is especially critical when in a medical or veterinary application, such as was the case in the example above. Below we will discuss how sheave alignment and belt tension affect the machine, as well as some best practices to get the job done and #keepitrunning.

Effects of Poor Sheave Alignment and Belt Tension

- Belts Too Tight: An overly tensioned condition will cause excessive radial load on the shafts and bearings, as well as an added electrical load on the motor. It will lead to misalignment during operation (deflected shafts), decreased motor life, decreased shaft life, premature wear on bearings, and an overall loss of efficiency.

- Belts Too Loose: A loose condition will cause belt slippage, and in turn, overheating. It will lead to a significant loss in efficiency, premature wear on belts and sheaves, and, through heat transfer, can decrease the life of the bearings and motor.

- Sheave Misalignment: Sheaves out of alignment will cause many of the same issues as an improperly tensioned belt, including overheating, slippage, and excess radial load. More specifically, misaligned sheaves will cause heavy vibration, as well as premature and uneven wear on the belts and sheaves.

Best Practices for Sheave Alignment and Belt Tensioning

- Sheave alignment and belt tensioning should be done somewhat simultaneously. The alignment process will affect the belt tension and vice versa. Don’t assume it’s in spec, check it!

- Install sheaves as close to the bearings as possible or reasonable. This reduces the load on the shaft and bearings by reducing the potential for shaft deflection.

- Check shafts and sheaves for runout before performing the alignment. Runout can cause many issues, including making alignment and belt tensioning more difficult.

- The closer the span between the motor sheave and the driven sheave, the more sensitive the machine will be to misalignment or improper belt tension. A longer span will be more tolerant. Machine speed will also play a factor. The higher the RPM, the more wear over a shorter amount of time. Keep this in mind.

- Check sheaves for wear using a sheave gauge. Gaps 1/16″ or larger indicate a sheave is worn and should be replaced. A belt will have a hard time gripping a worn sheave, which will translate into slippage and excessive heat.

- Use a sheave gauge to check sheaves for excessive wear.

- Check belt tension using a pencil gauge (with corresponding belt tension spec chart) or a frequency meter. Both methods are accurate and easy to perform if done correctly. In general, you should tension belts as follows: using a spring scale, press down on the belt in the approximate center of its span (on the tight side), to deflect the belt 1/64″ per inch of span length and observe the force required to do so. If you are not sure of the belt span length you may also use the center-to-center distance of the pulleys, which will be similar. Tension the belts until the force required for this deflection equals the belt manufacturer’s maximum recommended force values for the specific belts you are using. Make certain this force does not exceed the machinery’s design loads. The force values for all belts should fall within 10% of each other.

- You can align the sheaves using a cord, but the quickest and most accurate way is a laser pulley alignment tool such as the Easy-Laser XT190. The XT190 works for all types of belt drives, as well as chain drive applications. The benefits of seeing offset, angularity, and twist simultaneously on the screen, while being able to make live adjustments, makes sheave alignment with the XT190 quick, easy, and accurate.

Does It Make a Difference?

In the scenario above the difference between a heavy vibration and a smooth running machine was a slight alignment adjustment and 2 lb. reduction in belt tension. That’s it! When it comes to installing and maintaining industrial machinery, the devil is in the details. Don’t assume it’s right, know that it is using knowledge and the proper tools available.

Download our 5-Step Sheave Pulley Alignment Procedure for a simple and effective procedure for sheave pulley alignment of belt-driven equipment!

by Diana Pereda

In almost every heavy industry, you will find rotating machinery. You could say that rotating machinery makes the industrial world go round. Unless, of course, it doesn’t.

When rotating machines go awry, it can be nothing less than catastrophic. At the very least, when there is misalignment, the result is unwanted heat, noise and vibration, as well as an increase in fuel usage, a shortening of the lifespan of components and potentially the need to shut down operations and replace or repair key mechanisms. As a snapshot, rotating machines that need precise alignment to function optimally include crankshafts and camshafts within internal combustion engines, pumps, compressors and centrifuges in the process industry, wind turbines in the renewable energy industry, and an enormous variety of machines within the automotive, marine and manufacturing sectors. The business case for ensuring optimum operational levels is crystal clear, yet even businesses with many years’ experience using rotating machinery will sometimes cut corners – and almost always to their cost.

Prioritizing productivity

Given the high level of engineering built into modern industrial equipment, productivity gains have tended to become increasingly incremental, with far fewer opportunities for innovative leaps forward. With this in mind, operational methodologies are now under closer scrutiny, with best practice being the primary focus of efforts to extend service intervals and maximize machine uptime.

Roman Megela is the senior reliability engineer with Easy-Laser, a company that produces laser-based alignment solutions for rotating machines across a variety of industries. He is very clear – not to say evangelical – about the importance of maintaining alignment within these machines. “In the case of machine installation,” he says, “it is crucial that the machine is installed on a flat and levelled foundation. It is a must to measure and verify the foundation to avoid distortion of the machine’s casing. If this is not addressed during the commissioning phase, the machine’s operational life will be reduced, by perhaps as much as 50%, from the very start. Also, at some point, misalignment will cause the machine to fail and it will need to be repaired, with the additional expense of technicians having to re-install it.”

Precision in compression

One area in which Megela is seeing an increasing need for both improved performance and greater machine lifespan is compressed gas systems; in particular reciprocating compressors. When it comes to maximizing their performance, he says, “precision is key – especially during the setup phase.” Manufacturers generally provide strict guidelines on how reciprocating compressors should be aligned and checked, and Megela says this is where laser measurement tools really come into their own, being able to take care of perhaps 90% of the required checks.

“That includes everything from making sure the foundations and base plates are flat and level, to checking for soft foot, aligning the shaft between the driver and compressor, and verifying internal alignment like bearing clearances and thrust settings,” he says. On top of that, he says, dynamic checks can be made, including tests for thermal expansion and pipe strain, “because over time, those can significantly affect performance.”

“Ideally, it should all be done with one system, ensuring the process remains consistent. And it’s not just a one-time thing. After installation, you need to recheck everything regularly to make sure the machine keeps running the way it should.”

Stability means sustainability

Megela is a great believer in prevention being better than cure and he travels the world, explaining to engineers and technicians that the correct alignment of machinery could literally add years to its lifespan, benefitting not only the company’s bottom line, but potentially the planet too. He explains that, in the last five years, the industry has changed dramatically in the face of a number of different challenges, “from Covid, through components shortage, then energy prices going through the roof. If you add the cost of downtime, which includes loss of production, plus maintenance costs, it makes it very difficult for a business to have money to invest in new assets. Every organization I speak to is trying to become more efficient and sustainable, utilizing their available resources. It’s true that every machine has to be overhauled at some point, but this should as much as possible be a planned event, not due to failure. If you can manage this, you can potentially extend the life of your machine by ten times – then you’ve opened the door to serious sustainability.”

In fact, Megela sees it very much as being at the heart of his role, to educate industry professionals about the benefits of greener operations. “Sustainable practices will help to cut down maintenance costs and keep machines running,” he explains. “That translates into reliable operation which can also have a major impact on the return on a company’s investment.” This seems to be common sense, but Megela says he has visited companies for whom components that should last for a number of years, are regularly being replaced within 12 months, due more often than not to a failure to check alignment. The result is unplanned downtime for machinery, and potentially the need to bring technicians in to carry out unplanned maintenance. If the machine happens to be on a ship, or an offshore oil rig, transportation and travel costs can rise exponentially.

An all-industry issue

On the complexity of some of the maintenance and repair processes, Megela says, “It’s always time-consuming to stop production, drain and purge systems, lock out and tag out machines.” He adds that, due to the complexity of their processes, businesses within the refining, chemical, petrochemical and energy production industries are likely to suffer the most when misalignment strikes. “It needs to be understood that alignment is a condition, not a task,” he says. “Keeping the alignment condition within the tolerances is the key to maximizing your overall uptime and the benefits of alignment are huge. Bearings will operate under designed loads, lubrication will remain unchanged, no strain will be added to the shafts, mechanical seals and couplings.”

Megela says some of the companies he visits are surprised at how regularly checks on alignment are required. He says, “We should check the alignment after the installation every three months. Only after nine months of repeating solid values should we start extending verification periods to up to two years. In this way, the life of a machine can be significantly extended, with the potential for huge long-term financial benefits.” Regular inspections of equipment will almost certainly identify a problem, as rotating machines will immediately respond to misalignment, with increased vibration, temperature, energy consumption and noise, and potentially leaking seals and compression capacity drop.

“When misalignment is identified, a plan for correction must be presented and acted upon, before there is potentially a catastrophic failure of the asset. Cutting corners at this point is always disastrous; there is nothing more economical than a perfectly aligned machine. The result is a long service life and minimal component wear and tear; that means a saving on replacement parts – a saving on natural resources, as well as the consumption of less energy. This is one of the ways we ensure industry becomes more sustainable.”

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

by Diana Pereda

Guest post by John Lambert at Benchmark PDM

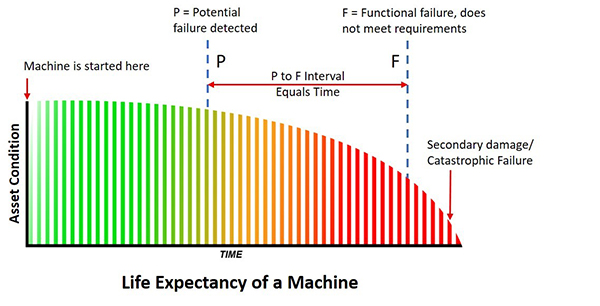

Recently I have been seeing the P to F interval curve popping up a lot on my LinkedIn feed and in articles that I have read. It was a concept that I was first introduced to when I was implementing Reliability Centered Maintenance into the Engineering and Maintenance department at the plant where I worked at the time. It was a great idea, that if done correctly is a maintenance benefit. Why, because it’s cost savings and cost avoidance. Let me explain this.

The P to F curve was used as a learning tool for Condition Based Maintenance. The curve is the life expectancy of a machine, an asset. The P is the point when a change in the condition of the machine is detected. The F is when it reaches functional failure. This means that it is not doing the job it was designed to do. For example, if it were a seal that is designed to keep fluids in and contamination out and is now leaking, it’s in a state of functional failure. Will this put the machine down? Probably not, but it depends on the importance of the seal and the application. This is an important point because the P (potential failure) is a fixed point when you detect the change in condition but the F (failure) is a moving point. Not all warnings of failure put the machine down very often you have options and time. Consider this: If I have a bucket that has a hole in it, it is in a functional failure state. But can I still use it to bail out my sinking boat? You bet I can!

Failure comes at us in many ways and obviously, we have many ways to combat it. If you detect the potential failure early enough (and it can be months and months before actual failure) it means that you can avoid the breakdown. You can schedule an outage to do a repair. It’s not a breakdown, the machine hasn’t stopped, it’s no downtime. This is cost avoidance and the plant can save on the interrupted loss of production because of downtime costs.

There are a lot of examples of cost avoidance and also of cost savings. For instance, at the plant I worked at we used ultrasound to monitor bearings. We detected a very early warning in the sound level and were able to grease the bearing and the sound level dropped. We saved the bearing of any damage, and we saved a potential breakdown so this is cost savings. Even if there is some bearing damage, the fact that we are aware of and monitor the situation lets us avoid any secondary damage.

It’s one price to replace a seal and it’s more if you have to replace a bearing in a gearbox. However, it can be very expensive to have to replace a shaft because the bearing has sized onto it and ruined it. Secondary, ancillary damage can mount up very quickly if you don’t heed the warning you are given with the P of potential failure. This warning of potential failure gives you time before any breakdown. The earlier the detection, the more time. Time to plan, and view your options. And what people tend not to do is failure analysis while the machine is still in service. A failure analysis gives you a great start on seeking out the root cause but starts right away, not when the machine is down.

Condition monitoring or as it’s often called Condition-based maintenance (CBM) does work. However, for me, there is a downside to this and I will explain why shortly. CBM is based on measurement, which is good because we all know to control a process we must measure.

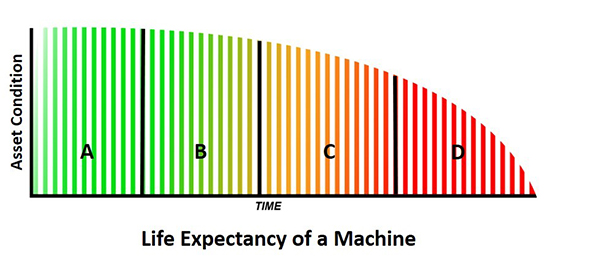

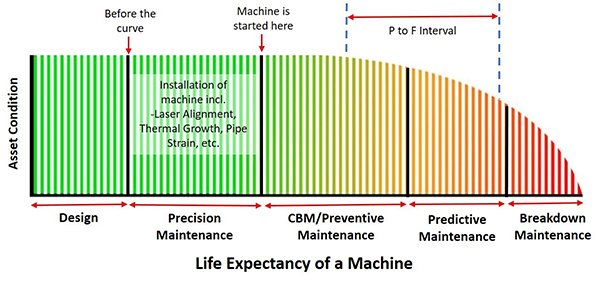

Consultants (and I’m guilty) like to put labels on things and you may see:

1. Design, Capability, Precision Maintenance

2. CBM, Predictive Maintenance

3. Preventive Maintenance

4. Run to Failure, Breakdown Maintenance

For me, the P to F interval curve starts when the machine starts. That means Design and Precision Maintenance is not in the curve and this happens before startup. A small point but it takes away from the interval meaning.

We use predictive maintenance technologies in CBM. Vibration, Ultrasonic, Infrared, Oil Analysis, NDT (i.e. pipe wall thickness), and Operational Performance. They are all very good technologies, yet it is a combination of cross-technologies that works best. As an example, vibration may give you the most information yet ultrasound may give you the earliest warning on a high-speed bearing. And then there is oil analysis which may be best for a low-speed gearbox. It all depends on the application you have which dictates what’s best for you. A lot of time and effort was placed on having the best CBM program and buying the right technology.

This, I believe, lead to the maintenance departments putting the focus on Condition-based maintenance! This I think is wrong because we still have failure. This means that CBM is no better than Predictive Maintenance. This doesn’t mean that I don’t recommend CBM, I do. To me, it’s a must-have but it does not improve the maintenance process because you still have machine failure. Machine failures fall into three categories Premature failure, Random failure, and Age-related failure. We want the latter of these. We know from studies that say that 11% of machine assets fail because of age-related issues. They grow old and wear out. This means that 89% fail because of some other fault. This is a good thing because it gives us an opportunity to do something about them.

These numbers come from a very famous study by Nowlan and Heap (Google it!) that was commissioned by the US Defense Department. It doesn’t mean these numbers are an exact reflection of every industry but the study but it has stood the test of time and I believe it has led to the development of Reliability Centered Maintenance. But let’s say it’s wrong and let us double the amount they say is age-related (full machine life expectancy). That would make it 22% and 78% would be the number of random failures. Even if we quadruple, it’s only 44% meaning random is at 56% and we are still on the wrong side of the equation. The maintenance goal has to be to get the full life expectancy for all their machine assets.

In order to get the full life expectancy for a machine unit, I think you have to be assured of two things. One is the design of the unit which includes all related parts (not just the pump but the piping as well). The other is the installation.

If you’re like me, and you believe that Condition Based Maintenance starts when the machine starts then you understand that there is a section of the machine’s life that happens before. You could make an argument that it starts when you buy it because, as we all know, how we store it can have an effect. However, what is important at this stage is the design and installation of the machine. In most cases, we do not design the pump, gearbox, or compressor but we do size them so that they meet the required output (hopefully). We do quite often design the piping configuration or the bases for example. All of which is very important but the reality is that maintenance departments maintain already-in-place machine assets. So, although a new installation, requiring design work is not often done, installation is. Remove and Refit is done constantly. And the installation is something that you can control. In fact, it’s the installation that has the largest influence on the machines’ life. The goal is to create a stress-free environment for the machine to run. No pipe strain, no distorted bases, no thermal expansion, no misalignment, etc.

Precision Maintenance was a term I first heard thirty years ago. It’s part of our M.A.A.D. training program (Measure, Analyse, Action, and Documentation). It’s simple, it means working to a standard. Maintenance departments can set their own standards. However, all must agree on it and adhere to it. This is the only way to control the installation process. This is the way to stop random failure and get the full life expectancy for your machine assets. The issue is that we do not have a general machinery installation standard to work to. Yes, we can use information from other specific industry sources such as the American Petroleum Institute (API) or the information from the OEM (both of these are guidelines) however nothing for the general industry as a whole. Well, this is about to change. The American National Standard Institute (ANSI) has just approved a new standard that is about to be published. I know this because I worked on it and will be writing about it shortly.

If you look at the life cycle of a machine, we need to know and manage the failure as best we can. If we only focus or mainly focus on the failure, we will not improve the reliability of the machine. We cannot control the failure. What we can control is the installation and done correctly this will improve the process giving the optimum life for the machine.

I sell laser alignment systems as well as vibration instruments. If a customer were to buy a vibration monitoring tool before they bought a laser system. I would think their focus is on the effect of the issue, not the cause. What do you think?

by Ana Maria Delgado, CRL

In industrial settings, rotating equipment such as pumps and motors demands exact alignment to operate efficiently around the clock. A frequent installation flaw—soft foot—occurs when machine feet fail to contact a flat foundation uniformly, or pipe strain exists, causing machine frame distortion that misaligns critical components such as bearing bores. This twisting or bending of the machine frame undermines the precision of machined internals, leading to vibration, wear, and inefficiency. Correcting soft foot is straightforward and vital, preventing these issues and ensuring long-term performance.

Why Flatness Matters: ANSI/ASA Guidance

Machine feet are designed coplanar and flat for stable mounting. Uneven bases introduce undesirable distortion. Per ANSI/ASA S2.75-2017, baseplate flatness (coplanarity) is paramount, requiring less than 2 mils of spacing between feet. Flatness directly affects shaft alignment; verify it first using a straightedge or dial indicator before installation.

Streamlined Correction Process

- Shim for Contact: Fill foot gaps with shims, limiting to 3–4 per foot for rigidity.

- Rough Alignment: Install the machine and achieve perform rough shaft alignment.

- Soft Foot Check: Use your laser alignment tool’s soft foot program, such as that in the intuitive Easy-Laser XT series, to provide clear graphical feedback on bolt adjustments. It identifies distortions in real time, guiding precise corrections without trial and error—this step is typically needed only once.

Valuable Resources

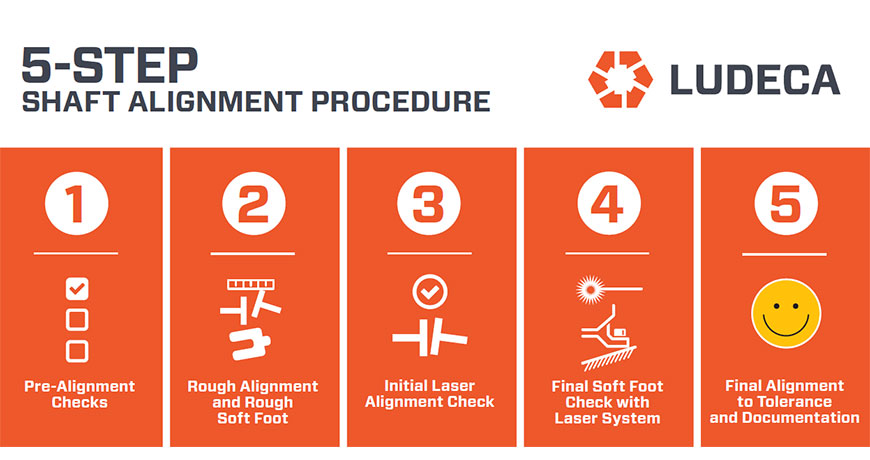

For practical insights, LUDECA’s free Soft Foot Find-and-Fix Infographic and 5-Step Shaft Alignment Procedure offer clear visuals and steps to implement effectively. These tools simplify detection and resolution, enhancing installation outcomes.

by Diana Pereda

Misaligned pulleys are one of the most common, and costly, causes of belt-driven machinery problems. Yet pulley alignment is often overlooked in regular maintenance routines.

What is pulley alignment?

Pulley alignment is the process of ensuring that pulleys (sometimes also referred to as sheaves) in a belt-driven system are positioned correctly relative to each other. The laser belt alignment tool projects a laser line that runs parallel to one pulley. This line acts as a reference to align the other pulley.

The benefits of pulley alignment

Whether in manufacturing, HVAC systems, or marine applications, proper pulley alignment can significantly improve performance, reduce wear, and save energy. Below, we explore the main benefits of pulley alignment and why it’s worth investing in accurate alignment tools.

Reduced energy consumption

When pulleys are misaligned, the belt doesn’t run smoothly. Instead, it slips, bends, or rides unevenly, which increases friction and resistance. This extra load forces the motor to work harder, consuming more energy.

Even small misalignments can lead to surprisingly large losses. A case study showed that proper pulley alignment can reduce energy consumption by up to 20 percent – a saving that quickly adds up in systems running 24/7.

Extended belt and pulley life

Misalignment causes uneven tension and side loading on belts, which leads to premature wear or even breakage. Heat generated from high friction will also degrade the belt material over time. The pulleys themselves also suffer, developing irregular wear patterns that eventually require costly replacement.

By aligning pulleys correctly, you ensure even load distribution, reduce vibrations, and minimize belt tracking issues. This extends the service life of both belts and pulleys and reduces the need for unplanned downtime.

Improved machine reliability

Poor alignment doesn’t just affect the belt drive. It can introduce vibration and stress that travels through the machine, affecting bearings, couplings, and connected components. Over time, this can lead to serious breakdowns and costly repairs.

Proper pulley alignment improves machine stability and reliability. You get fewer unexpected breakdowns and more predictable maintenance intervals with regular alignment checks.

Faster and safer maintenance

Alignment using straightedges or string can be time-consuming and there is always the risk of human error. Laser alignment tools eliminate guesswork by providing clear visual feedback and live digital readouts. Unlike traditional methods, they allow you to check alignment in both horizontal and vertical planes simultaneously, without rotating components or needing extensive disassembly. One technician can perform the job accurately in a fraction of the time. The result is faster alignment, fewer errors, and safer working conditions.

A smart investment with lasting returns

When you add up the energy savings, extended component life, reduced downtime, and faster maintenance, the total cost of ownership for belt-driven equipment drops significantly. In short, pulley alignment matters more than you might think, and even a small adjustment will bring measurable returns. And investing in a laser alignment tool like the Easy-Laser XT190 Belt Alignment Tool quickly pays for itself through these ongoing savings, especially in operations with multiple belt-driven machines or high uptime requirements.

Download our 5-Step Sheave Pulley Alignment Procedure for a simple and effective procedure for sheave pulley alignment of belt-driven equipment!

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

Align Your Belt or Chain-Driven Machines with Modern Laser Belt Alignment Systems!

by Diana Pereda

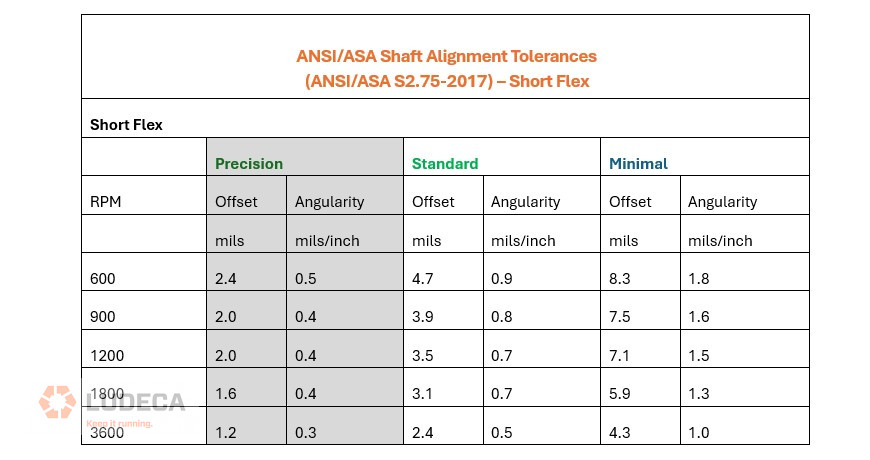

Some coupling manufacturers will sell couplings claiming that the coupling can take a large amount of shaft misalignment. While this is true for most good quality flexible couplings, this capability can be easily misinterpreted. Flexible couplings are designed to withstand, without damage, some shaft misalignment. Sometimes it is perceived that, since the coupling can take the misalignment, the machines can run under this condition without any consequences. When running machinery with significant shaft misalignment, bearing and seal life will be impacted, resulting in premature failures along with other types of machine damage. This difference is not due only to coupling manufacturers’ generosity; there is a valid mechanical reason for building flexible couplings that can withstand much more misalignment than what is good for the machinery they connect: this “extra” misalignment capacity allows certain machines to be deliberately misaligned in the unloaded “cold” and stopped condition to allow for the changes that will occur in the alignment as the machines are set to run and arrive at the fully loaded “hot” and running condition, and account for dynamic load shifts as may occur. This deliberate misalignment is called alignment to target specifications, and LUDECA offers a number of ways of determining what these might be. If the good quality flexible couplings would not have this additional misalignment capacity, some machines could never be “short coupled” together and would require a long spacer shaft between them to allow for the thermal growth or dynamic load shifts. Now then, with that said, we reiterate that the fact that a good coupling allows for lots of misalignment is never an excuse for you to allow such excessive misalignment to exist between your machines in the running condition.

The table below shows some key differences between the two sets of tolerances.

Therefore, for longer machinery life, it is always recommended to have the equipment laser aligned to standard industry tolerances such as (ANSI/ASA S2.75-2017), and not to the looser alignment tolerances allowed by the coupling manufacture itself. See tables 2 & 3 below.

Are Coupling Manufacturer Tolerances Good Enough for Shaft Alignment?

by Diana Pereda

Installing industrial electric motors is a critical step in ensuring the reliable and efficient operation of industrial machinery. However, the process of installing an electric motor can be complex and mistakes can easily be made, which can result in reduced performance, increased downtime, and ultimately, costly repairs.

To help prevent these mistakes, this article will highlight the most common errors made during the installation of electric motors and provide industry data to support the importance of avoiding these mistakes. From incorrect power supply and improper mounting to neglecting thermal protection and maintenance, this guide will provide a comprehensive overview of the key factors to consider when installing electric motors. By following these guidelines and avoiding these common mistakes, you can help ensure that your industrial machinery operates at peak performance for years to come.

-

Proper Power Supply:

Power supply misconfiguration is one of the most frequent blunders when it comes to motors. This can lead to under-voltage, over-voltage or wrong frequency, resulting in reduced performance or even motor breakdowns. The Electrical Apparatus Service Association (EASA) warns that an incorrect power source may bring about diminished efficiency and energy consumption as well as a shorter lifecycle for your motor! To keep away from these mistakes be sure you accurately assess the appropriate power supply requirements before selecting a compatible engine with your available source of electricity.

-

Proper Motor Mounting:

To avoid any complications caused by excessive vibration, make sure to carefully mount the motor in accordance with its manufacturer’s instructions. In fact, a Power Transmission Distributors Association study showed that up to 70% of motor failures are due to bearing problems stemming from incorrect mounting. Thus, for proper installation and optimal performance of your motor follow the recommended procedures set forth by its maker.

-

Keeping Thermal Controls in Mind:

Protection: Excessive heat is a frequent problem in electric motors, so it’s essential to have the right thermal protection measures in place to stop harm. According to the American National Standards Institute, temperature increases of not more than 40°C above ambient temperatures are recommended for most electric motors. To guarantee optimal thermal security, make sure you select an appropriately cooled motor (e.g., air-cooled or water-cooled) and ensure appropriate ventilation around it.

-

Evaluating Motor Duty Cycle:

It is essential to evaluate the duty cycle of a motor accurately and select one appropriate for your application. If you choose the wrong motor, it could lead to reduced performance and extended downtime according to NEMA (National Electrical Manufacturers Association). The duty cycle rate refers to how often an engine operates compared with its rest period – so make sure that you pick one tailored accordingly in order to maximize peak operation times!

-

Wiring:

To avoid potential damage to the windings and insulation, it is essential that the wiring be secured correctly and tightly. Shockingly, according to the National Fire Protection Association, more than half of electrical fires can be attributed to improper wiring. Therefore, for safety reasons alone, it is important to adhere strictly to local and national electric codes as well as frequently inspect all wiring connections for both tightness and protection integrity.

-

Cable Sizing:

Avoiding high resistance and heat buildup, as well as power loss requires the correct cable size. The Institute of Electrical and Electronics Engineers has stated that incorrect sizing may cause energy consumption to rise due to a decrease in motor efficiency. Thus, it’s important to assess the power requirements accurately in order to avoid mistakes and pick an appropriate cable size for your application.

-

Maintenance:

The honest truth is that even if your motor is installed perfectly, most of that effort is wasted if the proper maintenance practices aren’t adhered to. To promote the efficient operation of a motor and its enduring longevity, it is essential to conduct regular maintenance. In fact, following the manufacturer’s routine inspection protocol and servicing guidelines can prolong your motor’s lifespan by up to 50%, as stated in the EASA report. Regular maintenance is key to the successful preservation of your electric motor – don’t forget!

-

Environmental Conditions:

Yes, those are nuts. It is essential to protect the engine from moisture, dust, and other environmental elements that can cause harm. As noted by EASA, exposure to harsh conditions can reduce the motor’s lifespan by up to 50%. To guarantee effective protection, it is necessary to select a motor with an appropriate IP rating (e.g., IP54) and keep adequate ventilation near the engine so as not to accumulate dust or humidity. Sometime environmental issues can be local wildlife. In the example of one client who’s motor become a home for the local squirrel population.

In conclusion, the installation of electric motors is a crucial step in ensuring the reliable and efficient operation of industrial machinery. By avoiding the common mistakes outlined here you can help ensure that your electric motors perform optimally and avoid costly repairs. With the right approach and attention to detail, you can help ensure that your electric motors operate at peak performance and keep your industrial machinery running smoothly for years to come.

Thank you, ACE Electric Motor and Pump Co. for sharing this educational blog with us!

Download our Motor Storage Best Practices infographic for a basic reference guide to storing electric motors.

by Diana Pereda

Saving short-term money at the cost of long-term loss could never be a good idea. Soft foot is one of the most prevalent problems in rotating machinery, and the improper use of shims is one of the bad guys. This is way too common and is the cause of countless machinery problems worldwide. But let’s not let that happen. Instead, let us guide you through the ideal shims procedure, for an easier alignment task.

1. Initial check

For safety, always remember lockout and tagout of the machine. Then you can go about inspecting the foundation, grout, and baseplate with your eyes. If there is rust, scale, paint, or dirt, remove all of this from under and around the feet. Then you replace damaged shims with new ones, that are corrosion and crush resistant.

2. The right shims and the right number!

Don’t fall for the temptation to use homemade or low-quality shims! In the long run, this will cost you more than you gain short term. Usually, you will also need more shims if you use homemade ones. Use as few shims as possible. Three pre-cut shims should always be enough; in extraordinary situations, four could be needed. The fact is that using too many shims can, in itself, cause soft foot.

The use of anything other than high-quality shims is the main factor when it comes to machines being worn out beyond salvation. Pre-cut, stainless steel shims are perfectly flat and will, as a bonus of sorts, also prevent corrosion.

3. Measure and insert shim

Use a micrometer to measure the thickness of shims 1 mm and thicker. These thicknesses are nominal and not necessarily exact. Insert the pre-cut shims under the foot of the machine until they touch the bolt. Withdraw slightly.

4. Shim size

Use a shim size that adequately supports the load zone of the foot. Whenever the contact between the underside of the machine’s feet and the surface of the base plate or frame is less than perfect, we have what’s called soft foot. Ever sat at a wobbly table? Then you know. The annoying situation where one leg fails to reach the floor is bad enough. For a machine in an industrial context, this is more than just irritating; it will lead to damage if not taken care of.

5. Sandwich

With pre-cut shims, you’ll get a safer and easier machine alignment as well as better machine performance. Burr-free edges and rounded corners prevent injuries from occurring. Sandwich thin shims between thicker ones. If you have used high-quality shims, your machine should now be almost aligned. You are ready to move on to fine adjustment, i.e., aligning your machine using all the tricks of the trade.

Download our Shimming Best Practices Infographic which outlines 7 things to consider when using shims for machine installation or machine alignment plus Step Shimming.

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

Machinery Alignment Shimming – Things to note about precut stainless steel shims

by Diana Pereda

Before precision alignment is to be performed on rotating equipment, best practice dictates that there are a few things that should be checked, even before doing rough alignment.

One of those things is checking coupling and/or shaft runout. Runout is a condition where the centerline of the coupling or shaft has deviated from its true axis of rotation. To measure coupling or shaft runout, it is common to use a dial indicator with a standard magnetic base. Simply mount the magnetic base on a stationary surface. Then mount the dial indicator on the surface to be checked. For example, if checking radial runout on the coupling, we would place the dial indicator on the outer diameter of the coupling. We proceed by rotating the shaft of the machine and observing the face of the dial, looking for movement of the needle. This might tell us that the coupling was not bored concentric to the shaft centerline. If excessive runout is found on the coupling, it is good practice to check runout on the shaft as well. If there is also excessive runout on the shaft, this could mean that the runout at the coupling could be due to a bent shaft. At this point, and depending on the severity of the shaft runout, the shaft of the rotating machine may need to be replaced.

In some instances, it is also a good practice to check the axial runout on the coupling. This means we would place the dial indicator on the outer face of the coupling hub and look for movement of the dial. Excessive runout, in this case, would mean that either the inner diameter of the coupling hub was not bored concentric to its true centerline, or the coupling hub was not installed properly onto the shaft (i.e. when a dead-blow hammer is used to mount the coupling hub). Essentially, the axial runout of the coupling suggests that the coupling hub has an angle, in comparison to the shaft. It is very likely that you will find runout on almost every rotating machine that you measure. However, just like for precision alignment, we have allowable tolerances for runout. Typically, the maximum allowable amount for runout is 0.002″ (2 mils or thou). In the case of a higher RPM machine (more than 3600 RPM), a tolerance of 0.001″ (1 mil or thou) should be used. Although some people have thought that checking runout is a waste of time, it certainly is not. It confirms that the coupling was manufactured and installed correctly and that the shaft is not bent.

Download our 5-Step Shaft Alignment Procedure – a simple and effective procedure for shaft alignment of rotating equipment.

by Adam Stredel CRL

As a Technical Trainer for Ludeca, I teach the importance of following our 5-Step Shaft Alignment Procedure. As Millwright, I have completed many precision shaft alignments over the last 28 years of my career. In this time I have witnessed many other Millwrights and Technicians forget to do a thorough visual inspection of the foundation, grout, and baseplate before attempting the alignment. Following a procedure and ensuring that every section of it is done will help you achieve precision results in your shaft alignments, and get it done much faster.

Foundation

The foundation should be of adequate size and in good condition. A rule of thumb calls for concrete weight to equal at least three times machine weight for rotating machines, and five times that of reciprocating machines. Can you spot the good and the bad in the following pictures?

Grout

A grout base should be made of suitable material, in good condition, with no voids beneath the baseplate. If recently poured, proper cure time for both the foundation and the grout is important. Inspect the grout. What do you see?

Baseplate

The baseplate must be rigid so that no part of any machine foot moves more than 0.001” out of plane with the other feet of the same machine. Machine mounting pads must be level, flat, parallel, coplanar, and clean. What do you see in the following examples?

Download our 5 Elements Machine Installation infographic for an outline of 5 important elements of machine installation including Foundation, Anchoring, Isolation, Baseplate Level and Flat plus Alignment!

You’ve got it! Why not use it? Taking advantage of visual inspections.

by Diana Pereda

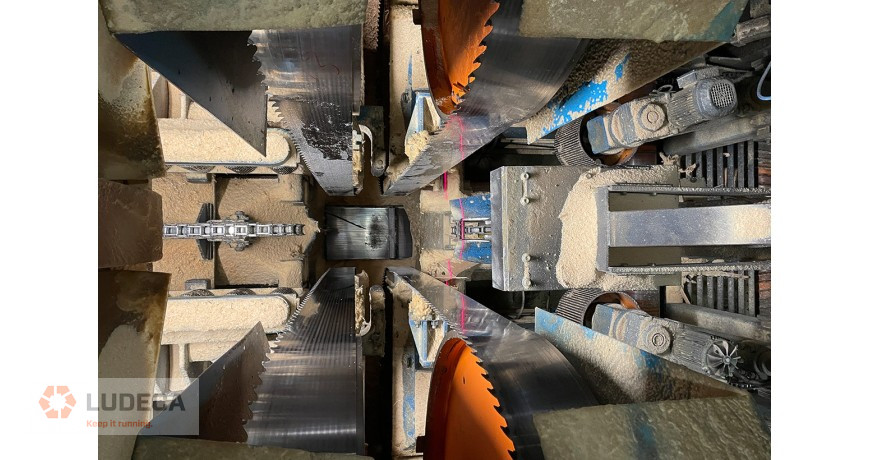

After more than 20 years in the industry, Peter Edström knows exactly what it takes to keep a sawmill running optimally. And with laser alignment, he’s making a real difference.

Peter Edström has been working with Swedish sawmills since 2000 and knows what’s required to create an efficient production line. Over the years, he has helped many customers overcome challenges related to machine settings and alignment. When Wood Control Technology was founded in 2021, Peter became one of the first employees – bringing with him decades of valuable experience into the young company.

Initially, the company focused entirely on selling control systems to sawmills, planing mills, paint shops and other segments of the wood processing industry. But before long, Peter began receiving calls from old contacts asking for help with mechanical issues. That was the start of a new business direction.

“When several of my former customers reached out for help with alignment problems, we decided to expand our services to include mechanical support,” says Peter.

Today, there are two people working with alignment and technical support – and demand just keeps growing.

Small errors, big consequences

A constant challenge for sawmills is maximizing lumber yield and cutting each board to the correct dimensions. To do this, they rely on advanced 3D optimization systems that calculate the most efficient way to saw each log.

“And those systems work,” Peter says. “But how much sawn lumber actually ends up in the yard? The optimization program might say we should get a certain volume, but when we look outside, it’s less. That’s because the sawing isn’t centered, and safety margins are added to account for minor wobbling. So the machines aren’t positioned exactly as the system expects, which leads to lower yield and less lumber in the end.”

Achieving optimal results requires precise machine alignment. And that’s where laser technology, combined with the expertise of companies like Wood Control Technology, makes a big difference.

From problem to solution

When a sawmill calls for help, Peter and his colleague head out to inspect the saw line. A typical line includes an infeed section that centers the log, a canter, four band saws, and an outfeed section that separates and transports the cut lumber. It’s common for issues to arise already at the log feed stage, such as log rotation or feed errors, meaning the log isn’t properly centered.

“We usually say that a 1 mm feed error in an otherwise standard sawmill can reduce yield by 1%. And 1% less yield means roughly $100,000 USD annually. So it’s a lot of money. And 1 mm is really not much for this industry.”

It typically takes two people about two days to align an entire saw group in a saw line, which fits perfectly into a weekend when production is paused. The cost? Often less than what just one hour of downtime would cost in lost revenue.

The importance of preventive maintenance

Peter sees a clear connection between regular alignment and financial health in a sawmill. It’s all about staying ahead of problems. Many sawmills are proactive and include alignment in their preventive maintenance routines, but far from all.

“Sawmills are good at fixing things. Some go a step further and use preventive maintenance, including mechanical inspections. That way, you catch the issues before they cause a breakdown. But overall, the industry still tends to wait until something breaks,” he explains. “It’s often a matter of cost. They cut back on things that aren’t immediately visible, like mechanical adjustments or lubrication. But those savings come back to bite you.”

“Mechanical settings don’t stay perfect over time, either. Parts get replaced, which can throw off the centering or cause looseness.”

Machines should ideally be aligned at least twice a year, or even four times if production volumes are high. But in practice, it happens far too rarely, Peter says. Many wait until quality issues become unavoidable or customer complaints start rolling in. By then, the financial losses are already significant.

Laser technology makes a difference

When Peter started working in the early 2000s, laser technology was still quite uncommon.

“At first, people were skeptical. They were used to wires and rulers, and optical tooling like theodolites were common. But now everyone wants laser,” he says.

He explains how much quicker and easier it is to set up a laser system compared to older methods.

“You set up the system, then do a rough alignment. You can follow the laser beam along the chains, it’s much faster than using a wire. And the results are more accurate.”

Peter has been using Easy-Laser systems since the beginning of his career and has even contributed ideas for the various fixtures included in the sawmill alignment system. A long-standing, close collaboration.

“I’ve used these systems for so many years, and they’ve come a long way. Even though the software and hardware evolve, like today’s XT980 sawmill system, it still feels familiar,” he says, adding:

“They’re stable, reliable systems with incredible repeatability. And they’re easy and intuitive to use. I love that it’s wireless. You can sit in different places and still see the live values. You don’t have to be inside the machine.”

The right setup maximizes yield

For Peter, it’s all about giving sawmills the best possible conditions for success, from the first log to the final board.

“Every sawmill would benefit from increasing yield, improving cut dimension control, and enhancing quality,” Peter concludes.

Thank you Easy-Laser for sharing this article about Peter Edström’s knowledge of alignment with us!

What is Machine Train Alignment and how important is it? Part 1

by Diana Pereda

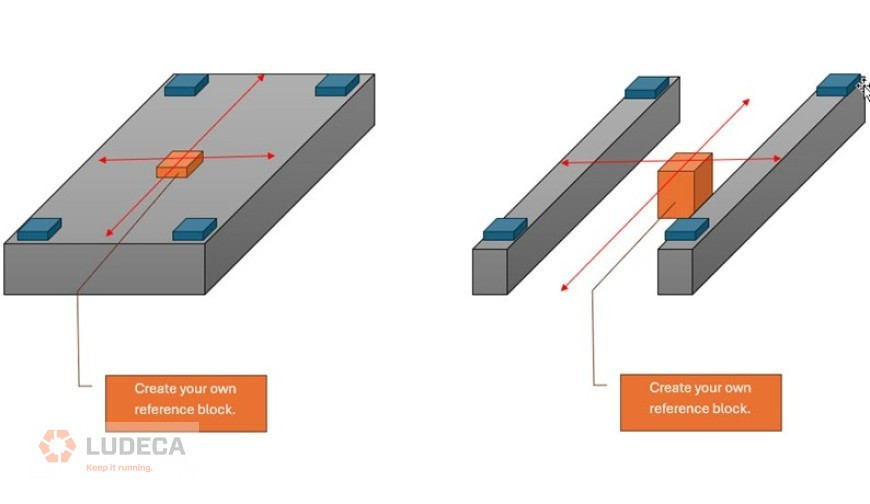

How many times have you replaced a motor and made sure you put the same shims back to ensure the new motor goes back in the same place as the old one? But doing so may end up bringing the issues that caused the old motor to fail to the new one. There is a better way to do things. The Easy-Laser XT550, XT660, & XT770 laser shaft alignment systems can help you make sure you don’t perpetuate an existing misalignment or soft foot problem over and over. Included with the system you also get an app called “Twist” which can help you determine if your base is flat. If you find it’s not, it will tell you what you can do to improve it. While the motor is off the base, create a common point or reference block in the middle of the base. The block can be made by the machine shop in-house and needs to have a top surface of 2 square inches to hold the measuring unit. See Figure 1 below:

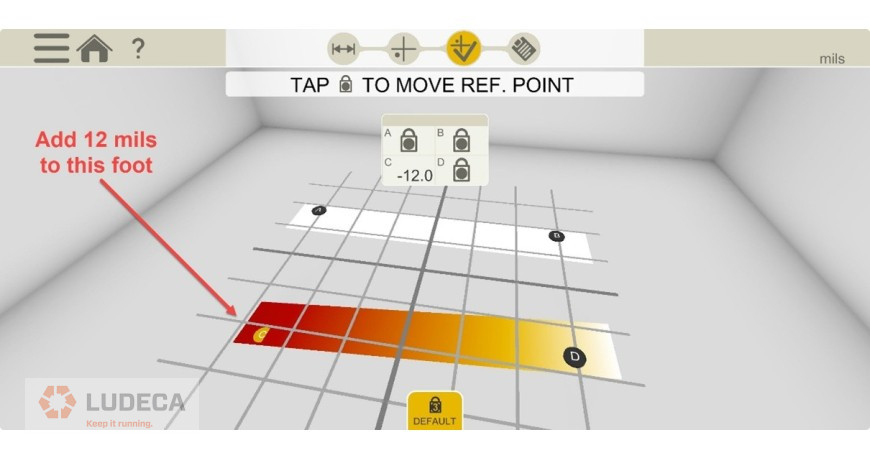

Once the measurement is complete, the Twist app will tell you which machine foot is off plane or not flat and it will tell you how many shims to add under the foot to compensate, see Figure 2 below.

Download our Flatness vs. Levelness using a laser to measure the two infographic for a reference guide to the concepts of flatness and levelness!

by Diana Pereda

Companies throughout America and the world use the Easy-Laser alignment systems as well as other laser systems for precision alignment. Ludeca has made it “easy and reliable” to perform precision alignment with a simple 5-Step Shaft Alignment Procedure that is easy to follow and accessible on Ludeca’s website in the Knowledge Center. Being a technical trainer for Ludeca, I always use this 5-Step Shaft Alignment Procedure in every training session!

This simple but straightforward guide will ensure that the mechanic, technician or millwright performing the alignment has a set procedure to follow “every time” an alignment is done. Using the Ludeca 5-Step shaft alignment procedure builds consistency into the alignment process for greater success.

It is very important when doing precision alignment that everyone is on the “same page!” So if you are a maintenance or reliability manager who has the responsibility of overseeing and ensuring that precision alignments are done correctly and done right the first time and you do not currently have a standard operating procedure (SOP) or an alignment procedure built into your best practices for your facility, then please consider implementing this at your workplace or at least drawing from this great resource. It takes your mechanics and millwrights step-by-step through a procedure that has proven itself time after time.

From Lock Out Tag Out all the way through final alignment documentation, Ludeca and Easy-Laser make it easy and reliable for you to Keep it Running!

What Machine Components Benefit from Precision Shaft Alignment?

by Diana Pereda

Chain drives are widely used in industrial settings throughout the world. Knowing the advantages and disadvantages of chain drives and how to properly maintain them can help you to keep them running as intended. Chain drives consist of a series of chain links which mesh with toothed sprockets. Chain Sprockets are locked on the shafts of the driving and driven machinery. Chain drives provide a positive form of power transmission. The links of the chain mesh with teeth of the sprockets and this action maintains a positive speed ratio between the driver and driven sprockets.

Chain Drive Advantages:

- Chain drives, unlike belt drives, do not slip or creep.

- There is no power loss due to slippage. This makes them more efficient than belt drives.

- Chain drives are more compact than belt drives.

- Chain drives are a better choice for slow speed drives.

- Chains can operate effectively at high temperatures.

- Chains do not deteriorate due to oil, grease, exposure to sunlight or age.

- Chains typically withstand chemicals and abrasive conditions better than belts in belt drives.

- Chains can operate in wet conditions.

- Chain drives are effective when several shafts are to be driven from a single shaft, as precise timing between the driven shafts is usually required.

- Chain stretch, due to normal wear, is a slow process.

- Chains require less take-up adjustment than belts.

Chain drive Disadvantages:

- Chains cannot be used where the drive must slip.

- Chain drives cannot accept much misalignment.

- Chain drives need frequent lubrication.

- Chain drives are noisy and can cause vibration.

- Chain drives do not have the load capacities of gear drives.

Download our 5-Step Sprocket Alignment Procedure – a simple and effective procedure for sprocket alignment of chain-driven equipment!

Align Your Belt or Chain-Driven Machines with Modern Laser Belt Alignment Systems!

by Diana Pereda

When a new technician enters their field of employment, the normal procedure for training is to send them out with older techs that have been doing the job for a while. This is a good old fashioned OJT (On The Job Training). The goal is to have the new tech up to speed quickly, and self sufficient to the point that they can be trusted to work on their own. Maybe, if they pan out, they can be sent later for formal training. Or, at least tested to achieve a certain level of certification. While they are learning the basics for operations and maintenance for their equipment, they will also be told to memorize certain numbers for the adjustments and settings for that same equipment. And this is where the problems start creeping in. Some of those numbers are being given as the specifications, with little to no understanding of how and why those numbers exist. Let’s look at alignment specifications, since that is what Ludeca deals with the most.

I am going to work with natural gas compression, since that is the industry where I have the most experience. The numbers that are always being tossed around are “5 & 5”, as in .005″ for offset and .005″ for angularity. I call that a classic field spec, not a true specification. There are so many things that those numbers do not address.

Here are a few of those things:

- How much thermal growth does each component have for this particular alignment? There are several different engine makes and compressor brands, which all have different models having different growth signatures.

- For instance, an Ariel JGK compressor is advertised by the manufacturer to grow .011″. And some of those can be coupled to a Caterpillar 3400 series engine, which is advertised to grow .015″. With this pairing, the engine would need to be left .004″ lower to compensate for that growth. Some compressors in that same size frame group can be coupled to a Caterpillar 3500 series engine, which grows .019″. That means the engine would actually need to be .008″ lower than the compressor when everything is cold, so that it will be in the correct position when the engine and compressor achieve full thermal growth.

- What is the Diameter of the coupling? While this has nothing to do with the tolerances, it changes everything if you are using the coupling diameter to reference a gap difference against. This comes from the old equation for correcting angularity when using dial indicators. AB/CD where AB is overall length of the movable component divided by the coupling diameter. And if you really worked it out, .005″ TIR on a 36″ coupling was much tighter than on an 8″ coupling. It makes it look like the entire industry was working on a sliding scale of accuracy, and when I asked about it, I was told that it didn’t matter as much on the smaller ones, because they are “cheap”.

- What is the rated speed of the equipment? Speed dictates the tolerances, plain and simple. Think of an engine built 60 years ago. To rev one up above, say, 5000 RPM would scare a lot of people. They would be sure that it would just come apart running that fast! Engines today rev much higher, with no thought being given to those extra few thousand RPMs. It has everything to do with the tolerances during the design and assembly process for the newer engines. We can run them faster because of the tighter specifications. Alignment is the same way. If a traditional Gas Compressor Tech tries to align a gas turbine the same way they would align an engine-driven compressor, it would be a short run and a long (and costly) repair.

And I know a lot of people will say, “but the coupling manufacturer’s specifications say that they can accommodate so much misalignment”. Yes, the specifications do indicate that a certain amount of misalignment can be tolerated, but only for intermittent lengths of time, like a cold start up, to allow the machines to “grow into alignment” with each other as they warm up and are put under load. The flex in a flexible coupling is normally to allow the machinery to run for a while, until full thermal growth and load is achieved which hopefully has everything in correct alignment. Much more important is to look at the internals of the equipment. How much misalignment can those parts withstand for extended periods of time? Certainly, much less than the coupling is built to take.

These were just a few of the things to consider when discussing tolerances and specifications. I was very careful to call the field numbers “Specs”, not specifications. Some of the specs given are just too arbitrary for the level of safety and operational efficiency needed for this type of equipment. Knowing the actual specifications, and even the reasons for them, is too important to ignore. With a little effort, using dealer contacts, available documentation, and a good search engine, correct Specifications can be found.

A Before and After of Alignment on a Caterpillar Engine mated to an Ariel Compressor

by Diana Pereda

In mechanical design, one of the core principles I learned is that “everything is a spring.” This concept underscores that all materials under stress behave like springs, which has profound implications for machinery installation and maintenance. Machines and the bases they sit on may seem to be perfectly rigid, but when the alignment tolerances required are at the nearest thousandths of an inch (0.02mm), more variables will need to be introduced.

A prime example is the use of torque wrenches, essential tools for ensuring precision. When installing components like a car engine’s valve cover, uneven torque application can distort the component, leading to gasket failures, leaks, or even structural breakdowns. This principle also applies to aligning rotating machinery, where even the slightest internal misalignment (referred to as “soft foot”) can distort machine frames.

The ANSI-ASA 2.75 shaft alignment standard specifies that soft foot should not exceed 2.0 mils (0.04 mm) per foot for optimal performance.

Torque wrenches play a critical role by providing consistent torque application, which is vital for making precise adjustments during alignment processes. This consistency eliminates variations in torque application that might occur with different operators or tools, simplifying what can be a challenging alignment task. Resources like Ludeca’s free Soft Foot Find-and-Fix Infographic offer practical guidance on this issue.

Moreover, understanding the nuances of torque application – whether it’s wet or dry (with or without lubricants) – is crucial for safety and functionality. Wet torque reduces friction; hence less torque is needed compared to dry scenarios where friction is higher. For detailed guidance, resources like the Machinery’s Handbook – Industrial Press are invaluable in any maintenance setting, providing standards and best practices for torque application.

In essence, recognizing that every component can act as a spring helps in anticipating how they will react under stress, thereby guiding the meticulous application of torque to ensure machinery operates at peak efficiency and safety.

by Diana Pereda

Cardan Alignment can be done without removing the bracket when the following requirements are met:

- There is enough room to rotate lasers and the shaft at least 40 degrees.

- A laser shaft alignment system such as the EASY-LASER XT660 or XT770 is available.

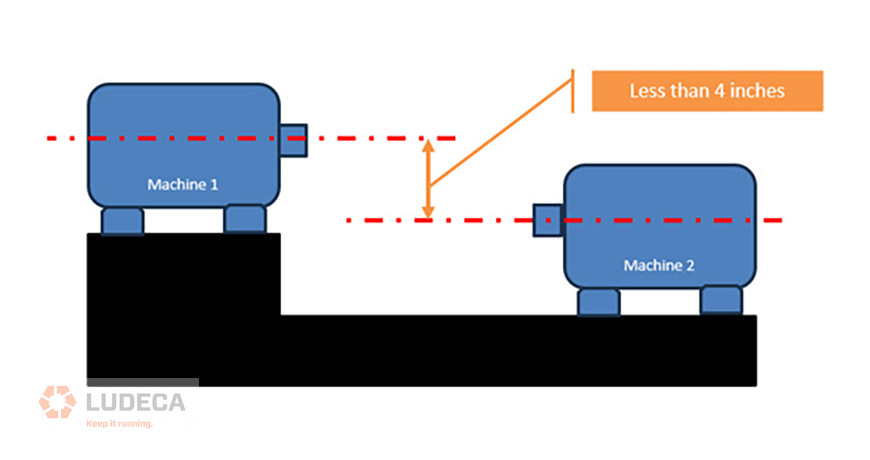

- The offset between machine shaft centerlines does not exceed 4 inches as shown in Figure 1 below.

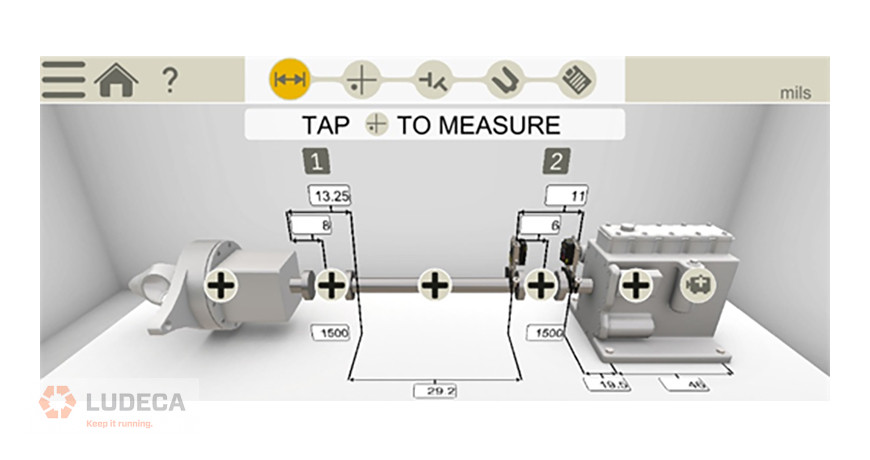

Using either of the recommended laser alignment systems, select machine train alignment and configure the machine train so as to make the cardan shaft the middle machine. Now measure the misalignment across the left-hand U-joint (Coupling 1) and then the right-hand U-joint (Coupling 2). See Figure 2 below.

Machines with a cardan shaft have a predetermined offset between them. Therefore, we only need to make sure that the two machines are parallel to each other by eliminating any angularity between them.

Correcting the angle of the movable machine can be done by making the position value of the front foot and rear foot of the movable machine the same with respect to the stationary machine.

Click here for additional information or to download the step-by-step procedure!

A Successful Cardan Shaft Alignment on a Boat using Multipoint Measurement

by Diana Pereda

This is where it all gets interesting.

Thermal growth is mainly caused by the temperature difference in a machine when it is offline (cold) vs. online (hot). High temperature causes metals to expand, and different parts of the machine will expand differently depending on the material. This can cause a machine that is perfectly aligned while not in operation to be misaligned out of tolerance when it’s running.

How do we measure thermal growth?

Thermal growth can be measured by first taking an alignment reading when the machine is cold and again immediately after it stops, when it has reached full operating temperature. However, this method might not always be practical due to safety concerns.

Easy-Laser’s dynamic measurement brackets and the program EasyTrend are specially designed to deal with this. The brackets allow us to mount the laser measuring units on the driver and driven machines and measure alignment values in real-time, while the machine is operating. They are specially designed to prevent the transfer of machine heat to the measuring units, as you can clearly see in the infrared image below.

Gearbox – generator alignment on site

Our partner SCI was recently called to perform an alignment job in an energy plant outside of the city of Puebla in Mexico. The machine train consisted of a combustion engine, a gearbox, and an electric generator. The customer stated that they had aligned the train before, aiming for a tolerance within 0.06 mm in cold condition. The manufacturer had not provided any information about thermal growth.

Fransisco Sosa from SCI explains:

“We decided to perform some measurements using the EasyTrend program to achieve precision alignment of the gearbox–generator coupling during operating temperature (hot condition).

In this case, the dynamic measurement brackets were very helpful. Once they were mounted on the machine, we started measuring from the startup of the equipment and then for approximately 3 hours to see the thermal growth.

We were able to see in real-time that the gearbox moved 0.53 mm in the vertical direction due to its operating temperature, which was almost 80 °C. Movement in the horizontal direction was negligible. The operating temperature difference between the gearbox and generator was approximately 30 °C.

When the equipment was turned off, we kept measuring the dynamic movement without vibration during the cool-down period (8 hours), to corroborate the result.”

The measurement report

The black line in the graph shows the offset and angularity in the vertical direction, and the yellow line shows the horizontal direction. The expected thermal growth can clearly be seen.

When checking the alignment after some time of operation it showed the equipment was well within tolerance, as you can see in the report.

In conclusion, dynamic measurement is a great complement that offers valuable real-time insights into your machine’s performance. It will not only help to extend its service life but also minimize downtime and maintenance costs – and at the price of two additional brackets, that is cheap insurance!

Thank you Easy-Laser for sharing this informative article with us!

Watch our Shaft Alignment Know-How: Thermal Growth video to learn the importance of accounting for thermal growth on rotating equipment.

Thermal Growth in Alignment Components: Achieve Reliable Results With These 4 Tips

by Diana Pereda

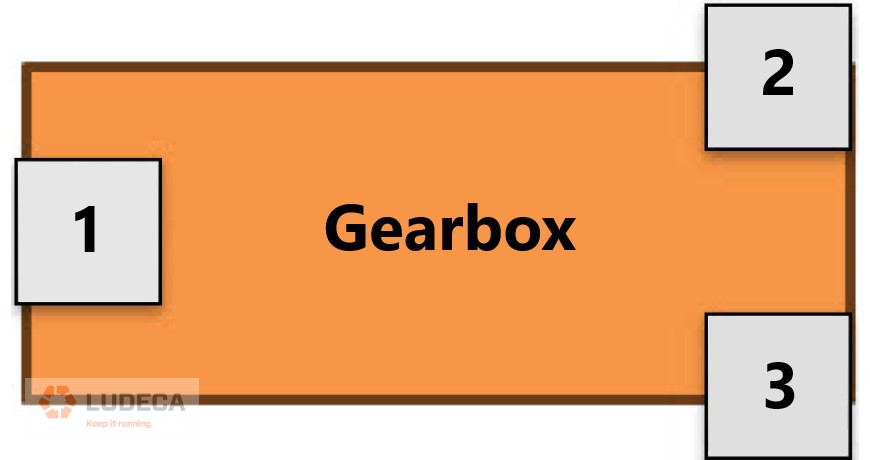

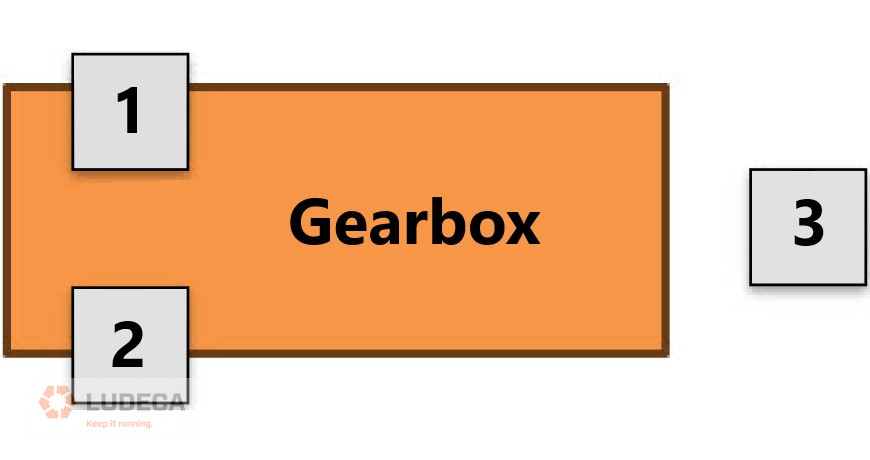

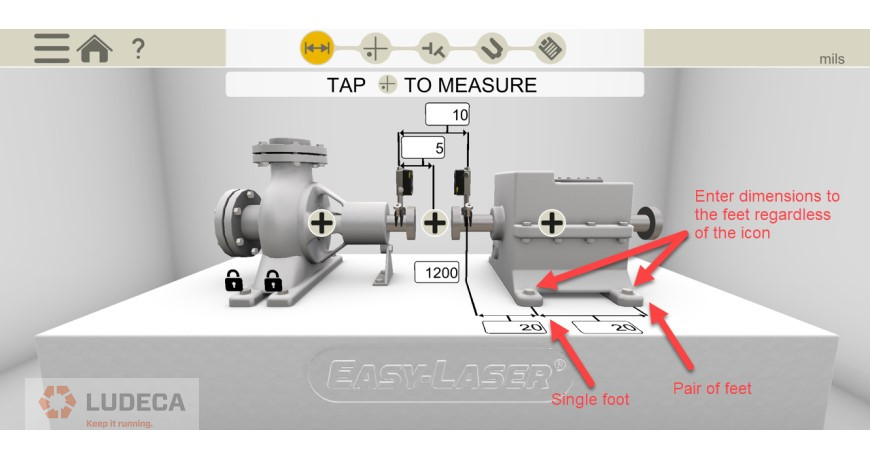

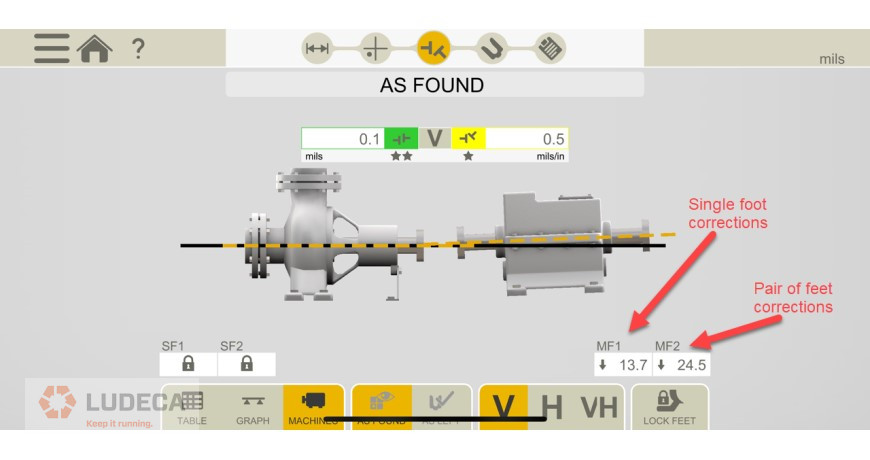

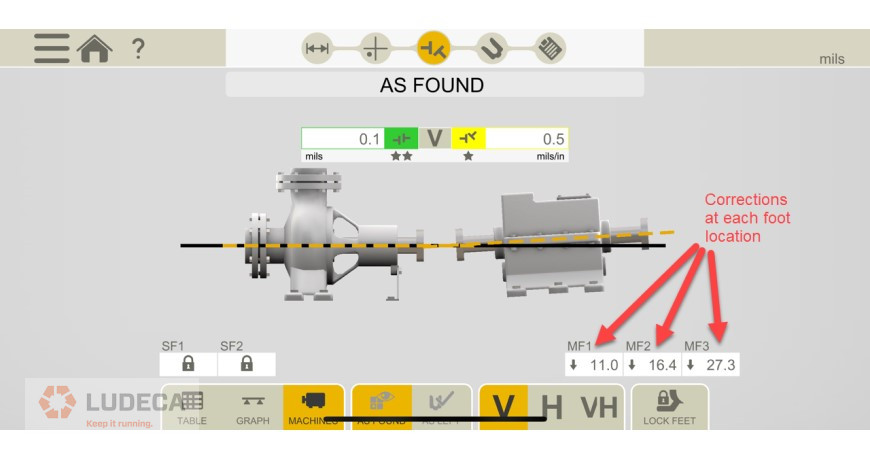

When dealing with the alignment of a gearbox that has 3 pairs of feet, there are three possibilities when using the Easy-Laser Generation XT systems:

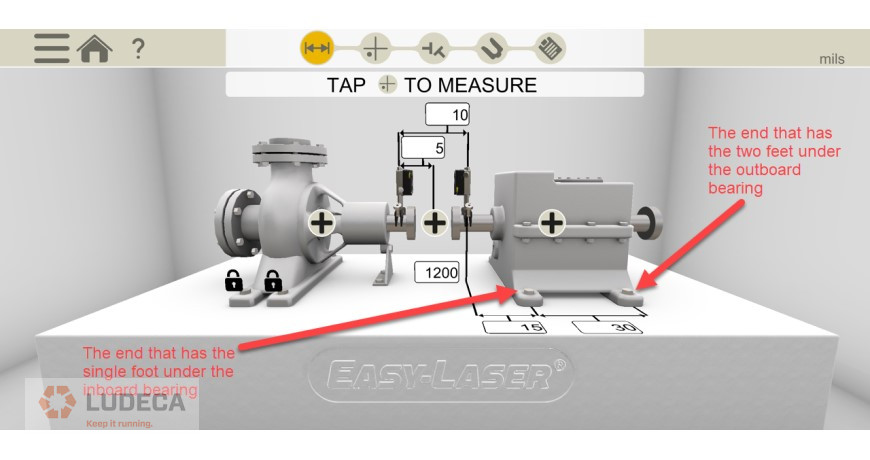

Option 1:

If the feet are located under the shaft and bearing housings, view the gearbox as a normal 4-footed machine. This will give you inboard and outboard corrections for the feet. The end that has the 2 feet should be corrected evenly, and the 3rd foot should be corrected as per the screen.

- Example foot configuration:

Dimensions set-up:

Results view:

Option 2:

If the feet are not located under the bearing housings, you will still view the gearbox as a normal 4-footed machine. Enter dimensions to the feet and disregard the icon or image of the machine on the alignment tool. Just like in Option 1, the end that has the 2 feet should be corrected evenly, and the 3rd foot should be corrected as per the screen.

- Example feet configuration:

Dimension set-up:

Results view:

*Note for Option 2: The location of the single foot will not affect the set-up or results. If the single foot was on the outboard side the process would be the same.

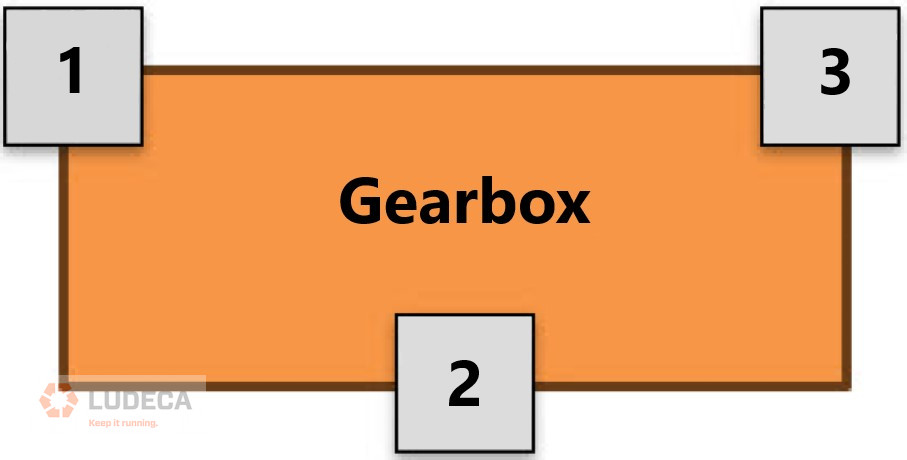

Option 3:

If the feet are on the sides of the gearbox, or not under that shaft or bearing housings, then configure the gearbox as a 6-footed machine. This will give you corrections for the inboard, middle and outboard feet. Correct accordingly at each foot.

- Example foot configuration:

Dimension set-up:

Results view:

3 Signs your Gearbox, Pump and Motor Shafts are not in Alignment

by Diana Pereda