A few things that should always be inspected during belt PM’s are:

- Inspect grooves for V-belts for wear using a sheave gauge following supplier recommendations.

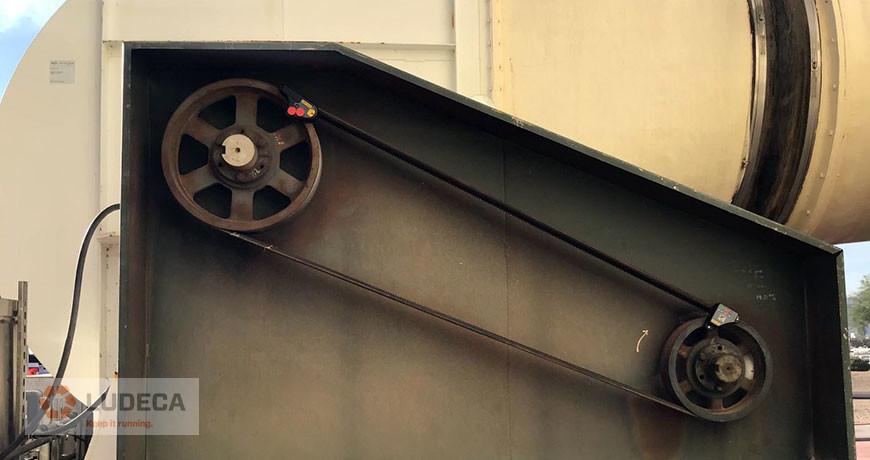

- Rusted or pitted sheaves should be replaced. Otherwise, belt damage/wear and premature failure can easily result.

- Shiny grooves should not be overlooked and can indicate heavy wear.

- Corrosion on the sheave and especially in the grooves will build up and rapidly wear the belt and result in premature failure. Sheaves should be replaced if corrosion is found.

- Bent sides can introduce wear and damage.

- Replace all belts and never a single belt. Mixing old and new belts results in the load not being shared evenly and could easily lead to damage, premature belt failure and sheave wear.

- The same manufacturer should always be used. In other words, do not mix and match belts from different manufacturers on the same drive.

- Noisy belts can be identified using a squirt bottle with soapy water. Spray the belt during operation with the soapy water. If the noise level changes, then the belt is part of the problem. It should be inspected for damage, proper tension, etc. If the noise remains, then most likely the belt is not part of the problem.

- Ensure that the sheaves are properly aligned. Misalignment will result in premature wear and damage.

Download our Belt & Chain Storage Best Practices which has some basics things to prevent belt and chain damage and contamination thus maximize parts life and performance.

Filed under:

Alignment, Maintenance Tips by Trent Phillips CRL CMRP - Novelis