In our previous blog, we discussed the: Shaft Alignment Measurement Mode: 9-12-3 The Classic Three-Point Method. In this blog, we continue with the next method: EasyTurn™.

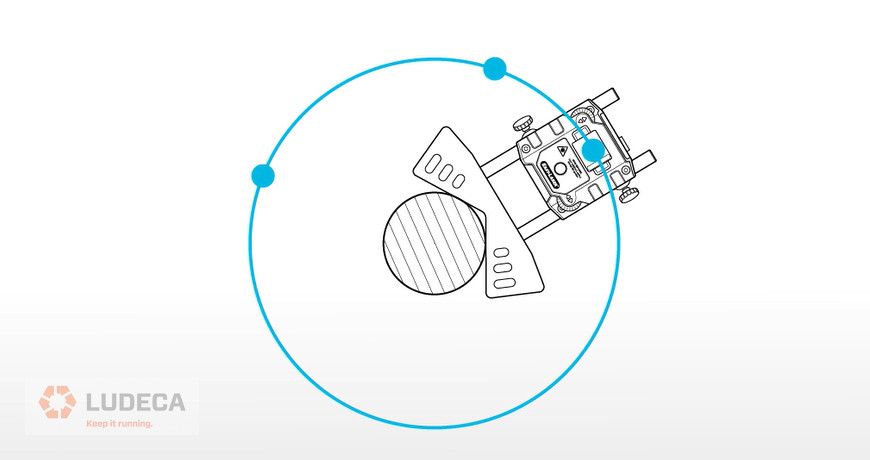

The EasyTurn™ shaft alignment measurement mode allows you to begin the measurement from any location and take a total of three points. The points can be taken at any rotational position of the shafts and can be as close together as 20 degrees for a total rotation of only 40 degrees. This measurement mode is designed for the Easy-Laser XT440 laser shaft alignment tool and can be used to tackle almost any alignment you encounter. Below are some examples:

Easy to rotate machines:

- Take three points at approximately 120 degrees to cover a full rotation of the shaft evenly.

Difficult to rotate machines:

- Rotate as much as possible each time to take your three points. Keep in mind you need to turn at least 20 degrees before you take your next point.

Uncoupled alignments:

- Using the OLED display on top of each laser/detector unit, rotate both the S and the M measurement units individually to the same rotational position or angle. This will simulate the machines being coupled. This allows you to take the three points as if the machines were coupled.

High vibration:

- By using the filter located at the bottom of the measure screen we can compensate for environmental vibration. The higher the filter value the more filtration is applied. Select the lowest value where the readings stabilize.

Watch our 5-Step Shaft Alignment Procedure [Motion Graphic] which outlines an easy and effective way to align your rotating equipment and brings you one step closer to best practices for your alignment program.

Filed under:

Alignment by Carlos Bienes CRL