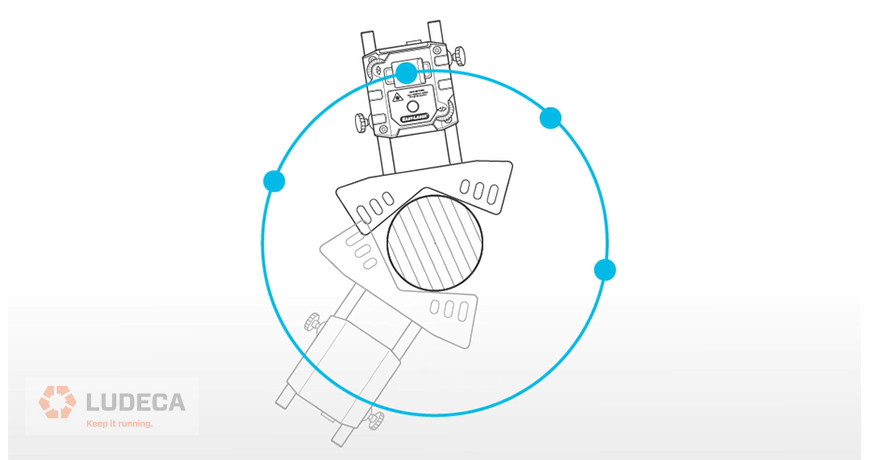

In our previous blog, we discussed the: Shaft Alignment Measurement Mode: Multi-Point Method. In this blog, we continue with the next method: Uncoupled Sweep.

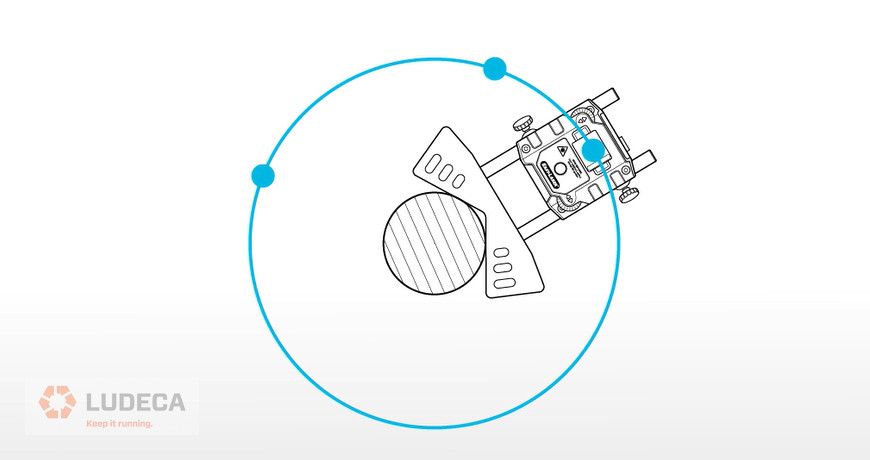

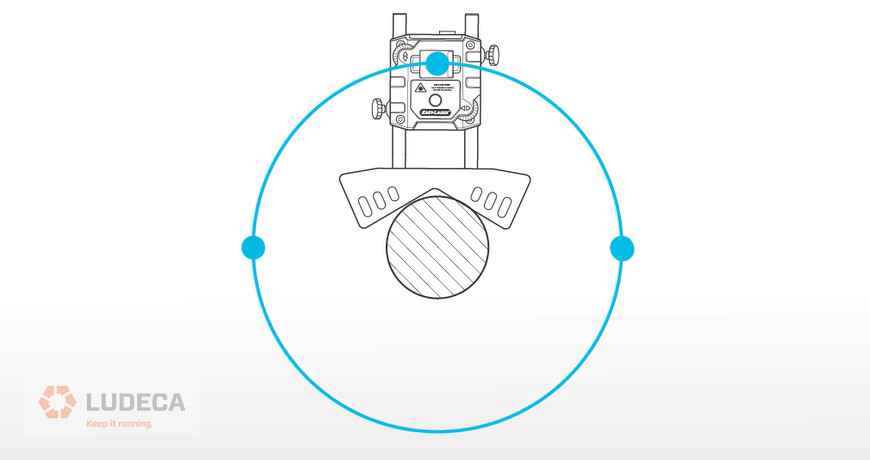

The Uncoupled Sweep Measurement mode allows you to measure uncoupled machines with ease. Start from any rotational position and take measurements by rotating the shaft with the S-laser in front of the shaft with the M-laser and vice versa, essentially passing one laser in front of the other, alternating. Uncoupled sweep is ideal for machines that are difficult to rotate or machines that cannot be rotated at all (in which case you slide the laser brackets around).*

Below are some examples of machines that are difficult or not possible to rotate:

- Gas turbines.

- Wind turbines.

- Gear boxes.

- Mine rock crushers.

- Ball mills.

This measure mode is available on the Easy-Laser XT770, XT660, and XT550 laser shaft alignment systems.

*Note that in these cases you will not actually be measuring centerlines of rotation, and the accuracy of your results will depend on shaft or hub, out of roundness and the care with which you reposition the measurement components each time.

Watch our Shaft Alignment Know-How: Repeatability to learn the importance of achieving repeatability of measurements before making alignment corrections.

Make Uncoupled Laser Shaft Alignment Easy with These Two Tools!

by Diana Pereda

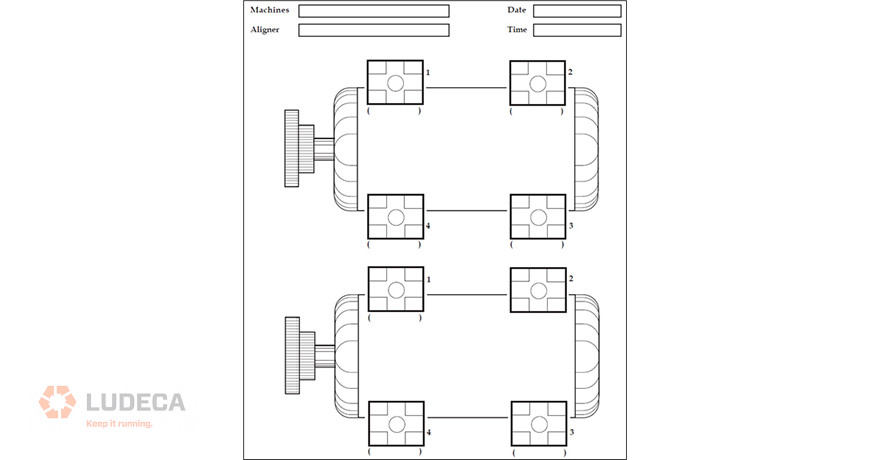

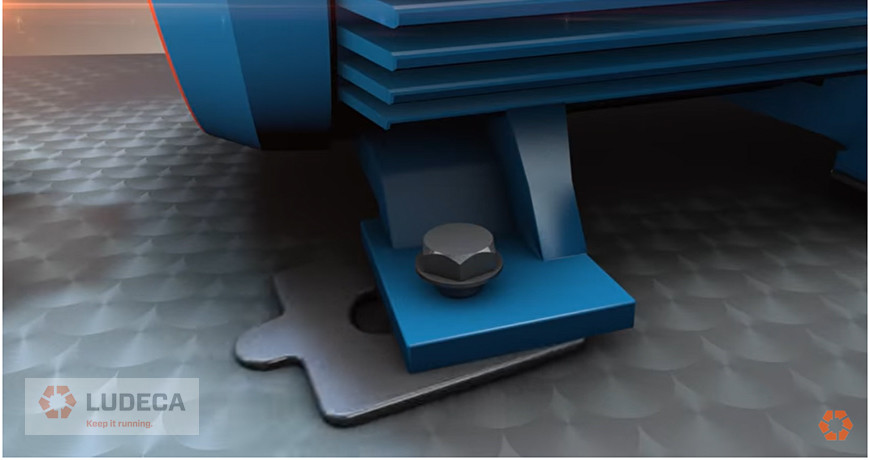

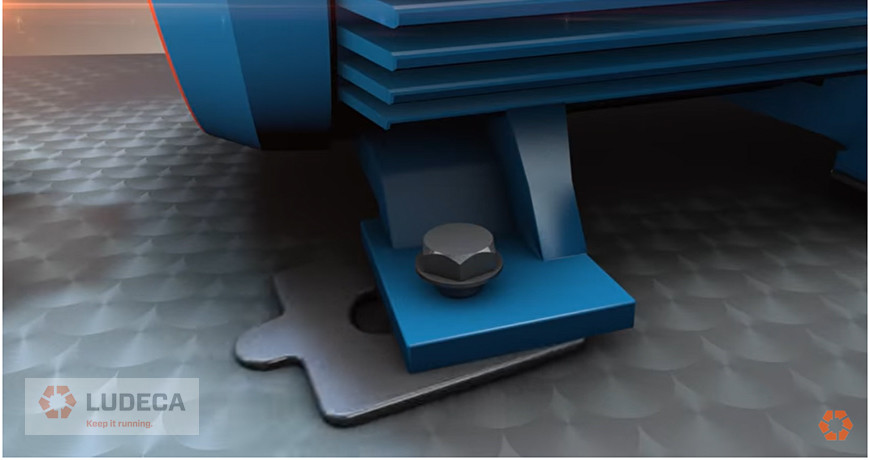

As part of our training program, we simulate various scenarios, to teach trainees how to see through a problem to a solution. To this end, the Soft Foot Analysis Form is a simple yet effective aid. Soft foot is machine frame distortion. It is evidenced by the movement of the machine shaft as the anchor bolts are tightened or loosened. How the shaft moves is subtle and depends upon the specific machine condition producing the casing distortion.

The Soft Foot Analysis form:

After reading all four feet with a laser shaft alignment system mounted on the machine shafts, the form asks you to feeler gauge the airgap at each corner of the feet that have been determined to be “soft”, with the other three feet tight. Miking the outer three corners of the foot is sufficient. Filling out the form allows you to visualize a “picture” of what is going on by comparing the shape of the airgaps to each other. This in turn leads to efficient diagnosis and correction of almost every kind of soft foot.

All the laser shaft alignment tools can do is detect if a soft foot condition exists since it is observing the reaction of the shaft as a foot is loosened. However, it cannot immediately tell you how to correct the problem.

The Soft Foot Analysis Form, when used in conjunction with our “Soft Foot Find-and-Fix Infographic”, helps you to determine which foot to shim and how much, or to determine if you have a ‘Bent’ foot condition.

The complete diagnostic procedure can be found in the LUDECA Shaft Alignment Training Manual, which every trainee receives as part of a LUDECA alignment training course. Please contact us for more information.

Watch our Shaft Alignment Know-How: Soft Foot to learn about the effects and importance of measuring and correcting Soft Foot when performing shaft alignment.

Make aligning your machinery easier, start by correcting Soft Foot

by Diana Pereda

In our previous blog, we discussed the: Shaft Alignment Measurement Mode: Continuous Sweep Method. In this blog, we continue with the next method: Multi-Point.

The Multi-Point measurement mode is among the most versatile measurement modes as it allows you to measure under any condition. It lets the user begin the measurement from any rotational position and take as many points as necessary to achieve excellent measurement quality every time. The points can be taken at any rotational position and can be as close together as 1 degree apart. A minimum of three measurement points is required, well distributed around the shafts to obtain accurate results. This measurement mode is designed for the Easy-Laser XT550, XT660, & XT770. Below are some examples:

-

Easy-to-rotate machines

- For machines that are easy to rotate, take a minimum of three points spaced approximately 120 degrees apart to cover a full rotation of the shafts evenly. However, taking more points is always better as it gives the system more data to work with.

-

Difficult to rotate machines

- For machines that are very difficult to rotate, the forces required to rotate the shafts may induce shaft deflection. Using Multi-Point we can relieve the rotational force and let the machine rest with each point taken, thereby avoiding shaft deflections completely.

-

Uncoupled measurement

- For uncoupled machines, trying to rotate both shafts together is next to impossible. Using Multi-Point, we can use the OLED display on top of each Laser/detector unit to align both the S and the M measurement units to the same angle. This will simulate the machines being coupled and allow us to get as many points as needed without any difficulties.

-

High vibrations

- For environments with high vibration from surrounding running machines or processes, using the Multi-Point measure mode lets us use the filter located at the bottom of the measuring screen to compensate for this environmental vibration. The higher the filter value the higher the vibration that can be compensated for. Since the shafts are allowed to rest at each measurement position as long as necessary to achieve stable readings, inaccuracies are eliminated.

-

Limited rotation

- For machines with obstructions to rotation or to line-of-sight for the lasers, the Multi-Point measurement mode allows you to accurately measure misalignment with as little as 40 degrees of shaft rotation. Take as many points as possible within the small arc of rotation available to you and you will still obtain reliable misalignment readings.

Watch our Shaft Alignment Know-How: Why Alignment to learn the benefits of precision machinery alignment.

by Diana Pereda

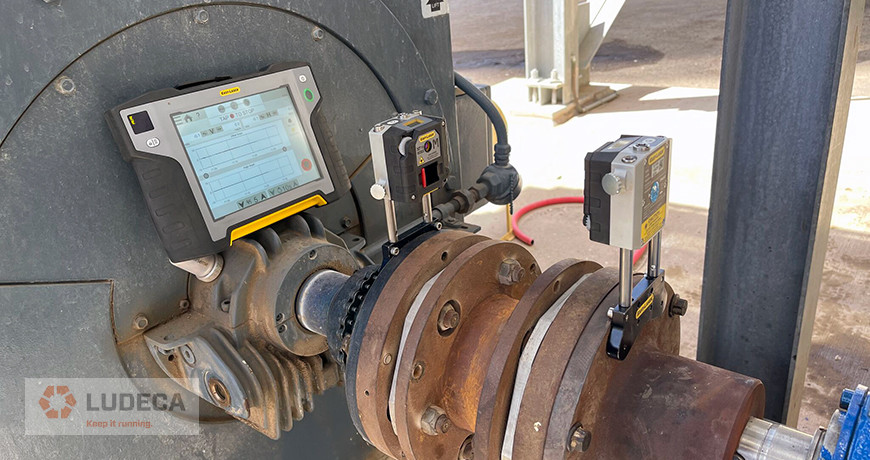

When purchasing a laser shaft alignment system, consider the following things to ensure you choose the most suitable and effective solution for your specific needs:

- Accuracy and Precision: Look for a laser shaft alignment system with high measurement accuracy and precision. The system should provide reliable and repeatable results for precise alignment adjustments.

- Ease of Use: Choose a laser shaft alignment tool such as the Easy-Laser XT-series that is user-friendly and easy to operate. Intuitive interfaces, built-in help, and straightforward procedures like LUDECA’s 5-Step Shaft Alignment Procedure contribute to efficient and error-free alignment processes.

- Versatility: Confirm that the alignment system is versatile and compatible with a diverse range of machinery types and sizes. A flexible system should adapt seamlessly to various measurement applications, including both horizontal and vertical installations. It should include checking for Soft Foot as well as compensating for thermal expansion of the machines (thermal growth).

- Durability and Build Quality: Assess the durability and build quality of the laser alignment system. It should be designed to withstand the conditions of industrial environments—ideally rated for both IP66 and IP67 water-, shock- and dustproof.

- Range and Reach: Consider the measurement range and reach of the system. Ensure it can cover the distances and dimensions relevant to your specific machinery and application requirements. Preferably, it should have a distance measurement range of at least sixty feet to easily handle applications such as cooling tower fans and deep submersible pumps.

- Flexibility: Various applications may demand specific alignment measurement approaches. Having different measurement modes such as Continuous Sweep and Multipoint allows the system to adapt to the specific requirements of each application.

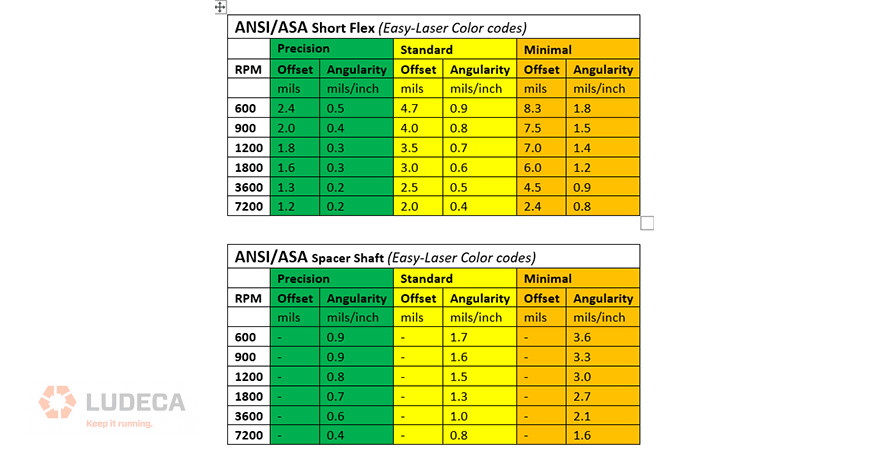

- Alignment Tolerances: Make sure the alignment system has a built-in tolerance check. The best laser alignment systems have built-in ANSI/ASA tolerances and perform their tolerance evaluation based on the condition displayed at the coupling and compare it to the standards for the operational speed of that machine. Even better systems allow you to use any alignment tolerances of your choice.

- Expandable: Choose an alignment tool that grows with your needs by offering the ability to add other measurement capabilities such as belt pulley alignment, vibration checks, straightness measurement, and flatness measurement.

- Reporting and Documentation: Look for a laser alignment system that generates comprehensive PDF reports containing alignment results, complete with photos and notes, and with the ability to email the report directly from the alignment computer. This detailed documentation serves as a valuable resource for maintenance records, ISO compliance, and quality assurance purposes.

- Training and Support: Check the availability of alignment training resources and support from the vendor. Adequate training ensures that users can make the most of the system’s capabilities, and reliable technical support is crucial for addressing any issues that may arise in the field.

By carefully considering these factors, you can make an informed decision when selecting a laser shaft alignment system that meets your specific requirements and contributes to efficient and reliable machinery alignment at your facility.

7 Reasons Why Machines Need Laser Shaft Alignment Technology

by Ana Maria Delgado, CRL

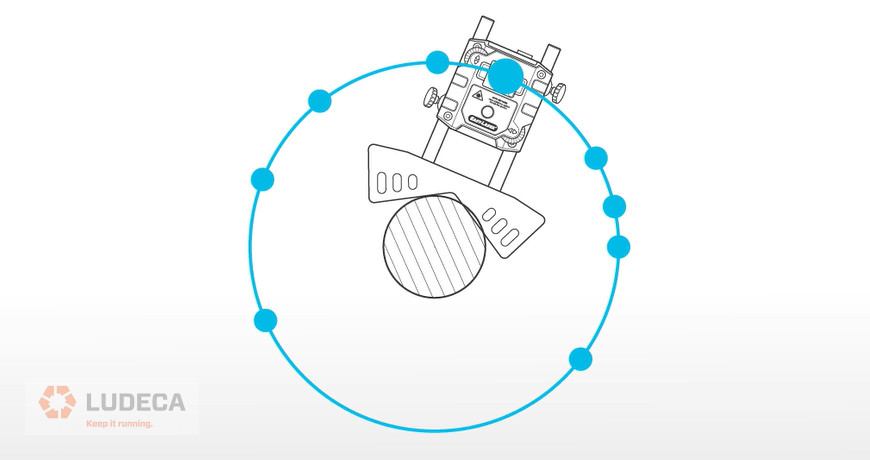

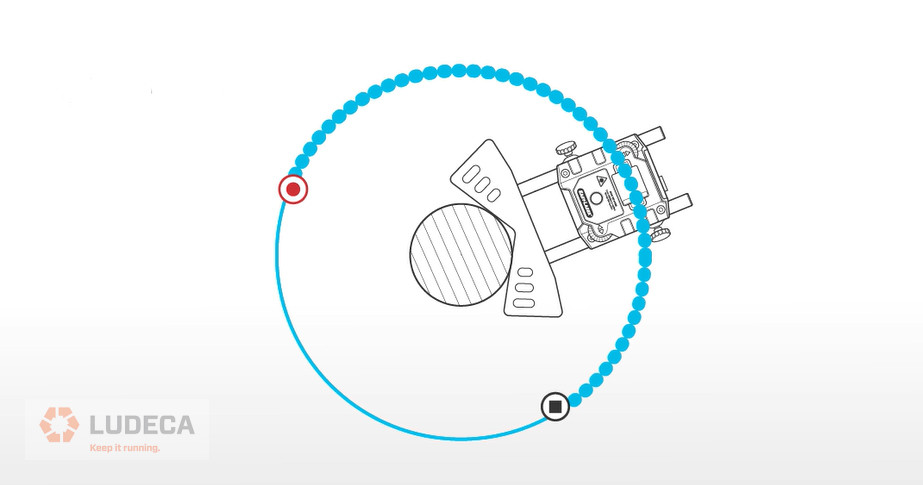

In our previous blog, we discussed the: Shaft Alignment Measurement Mode: EasyTurn™ Method. In this blog, we continue with the next method: Continuous Sweep.

The Continuous Sweep Measurement mode allows you to begin an alignment measurement from any rotational position. Simply rotate the shaft and let the tool record the points as you go around. With the ease of use, the capability to take hundreds of points, and a minimum requirement of only 40° of rotation, this measurement mode is the fastest and most straightforward way to measure misalignment. Sweep comes standard on the Easy-Laser XT660 and Easy-Laser XT770 laser alignment systems and can be used to tackle almost any alignment you encounter.

When to use the Continuous Sweep measurement mode:

- When the shafts are coupled together.

- When the difficulty in rotating shafts is easy to medium.

- When it is difficult to stop rotation once initiated.

- When only a small arc can be measured.

- Rotate slowly and collect as many points as possible.

Below are some tips on how to take excellent readings while using the Continuous Sweep measurement mode:

- Rotate the shafts smoothly.

- Always rotate in the same direction, preferably in the direction of rotation of operation.

- Try to make one continuous rotation.

- Slower rotation equals more points, and more points equals better results.

- Try to do a full revolution or 360 degrees of rotation if possible.

- Never take readings by rotating the shafts in different directions.

Watch our Shaft Alignment Know-How: Repeatability to learn the importance of achieving repeatability of measurements before making alignment corrections.

by Diana Pereda

In our previous blog, we discussed the: Shaft Alignment Measurement Mode: 9-12-3 The Classic Three-Point Method. In this blog, we continue with the next method: EasyTurn™.

The EasyTurn™ shaft alignment measurement mode allows you to begin the measurement from any location and take a total of three points. The points can be taken at any rotational position of the shafts and can be as close together as 20 degrees for a total rotation of only 40 degrees. This measurement mode is designed for the Easy-Laser XT440 laser shaft alignment tool and can be used to tackle almost any alignment you encounter. Below are some examples:

Easy to rotate machines:

- Take three points at approximately 120 degrees to cover a full rotation of the shaft evenly.

Difficult to rotate machines:

- Rotate as much as possible each time to take your three points. Keep in mind you need to turn at least 20 degrees before you take your next point.

Uncoupled alignments:

- Using the OLED display on top of each laser/detector unit, rotate both the S and the M measurement units individually to the same rotational position or angle. This will simulate the machines being coupled. This allows you to take the three points as if the machines were coupled.

High vibration:

- By using the filter located at the bottom of the measure screen we can compensate for environmental vibration. The higher the filter value the more filtration is applied. Select the lowest value where the readings stabilize.

Watch our 5-Step Shaft Alignment Procedure [Motion Graphic] which outlines an easy and effective way to align your rotating equipment and brings you one step closer to best practices for your alignment program.

by Diana Pereda

Measurement points are recorded at three fixed clock positions: 9, 12, and 3 o’clock. This is the classic three-point method which can be used in most cases. Below are some applications where this mode is preferred:

-

Vertically-oriented alignments:

- When performing an alignment on a vertical machine the automatic inclinometer used to determine the shaft’s rotational angle no longer works, because it is gravity operated. Therefore, use the 9-12-3 method so that you can manually set the angles or in this case clock positions.

-

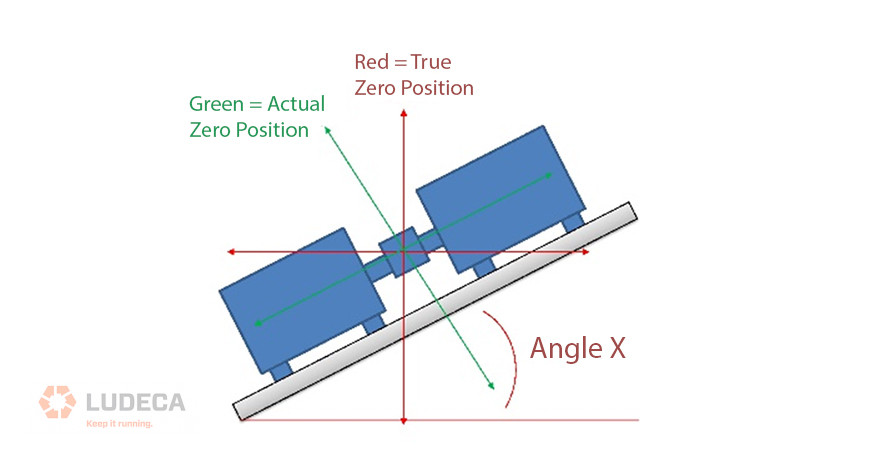

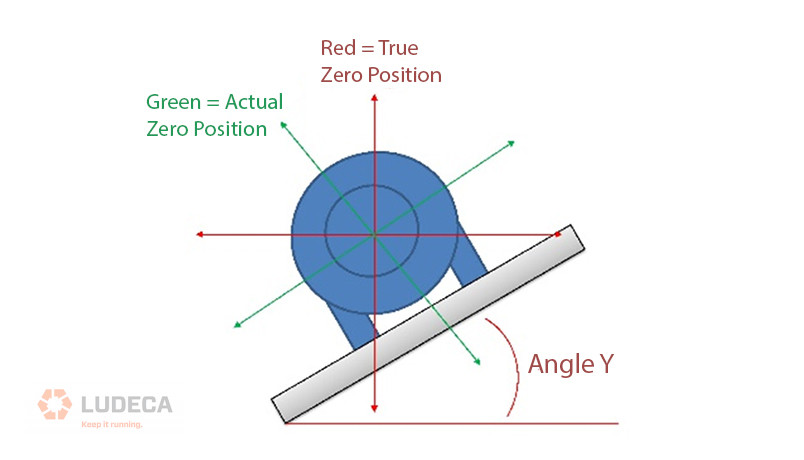

Horizontal machines which are installed at an angle due to specific industry or plant requirements. See examples below:

- Where the machine are at an angle axially and the sensor can’t determine true zero position. See Figure 1 below:

-

- Where the machines are installed at a rotational angle and the sensor true zero position does not coincide with the actual zero position. See Figure 2 below:

Download our 5-Step Shaft Alignment Procedure for a simple and effective procedure for shaft alignment of rotating equipment!

by Diana Pereda

Use ANSI Shaft Alignment Tolerances to help solve base-bound and bolt-bound situations. If a base- or bolt-bound situation presents itself during an alignment, take advantage of the outer limits of the tolerance envelope to help overcome the problem. It may be possible to optimally position the machine to meet the minimal ANSI tolerances and eliminate the bolt-bound situation altogether.

Say, for example, a machine is horizontally bolt-bound at the inboard feet. It is currently within precision angularity tolerance but is just shy of satisfying the offset tolerance. A possible solution for this is to try adjusting the offset by moving only the back feet and pivoting the machine about its front feet, thereby causing the offset to also fall within minimal tolerance, without compromising the angularity in the process. While this may cause the angularity to shift from precision to standard tolerance, this is perfectly acceptable so long as both the angularity and offset fall within ANSI Tolerances when you are finished. Some laser alignment systems even allow you to test the effect of proposed moves before you actually make them, thereby allowing you to determine if a proposed move such as the one described above will work before expending the time and effort actually trying it.

By evaluating the alignment situation objectively, and planning a move to remain within the tolerance limits of the alignment conditions, you can avoid unnecessary moves, machining, or hardware alterations to achieve the alignment. This will save you time and money!

Below are the ANSI tolerance tables for both short-flex and spacer shafts:

Watch our Shaft Alignment Know-How: Bolt-Bound video and learn about the options of achieving alignment when in a bolt-bound or base-bound condition!

by Diana Pereda

Within the industry, maintenance of machinery and plants is routine work. However, not everyone knows how to minimize future costs and risks for downtime from the start. Although it is so apparent!

Increased sustainability and reduced energy consumption

Everywhere in our society, machines are used for producing varying items, process materials, pump fluids, etc. These machines must be given the correct prerequisites to do the job for which they were designed. The importance of this increases with the naturally growing demands for sustainability and productivity that we face in our society. We are constantly reminded of the need for more energy-efficient solutions for the sake of our environment, right? This is where precision alignment with laser measurement systems comes in.

Flatness and level are fundamental

For a rotating machine to work as intended, it is fundamental that it is installed on a flat and level surface. This is to ensure proper lubrication of bearings, and that stresses on machine components equals that for which was calculated. With laser alignment systems from Easy-Laser you ensure a flat and level foundation, and that all base plates are plane-parallel in order not to force the machine into position when bolted in place.

Did you, for example, know that the recommended tolerance for machine foundation flatness is 0.2–0.4 mm/m, and that all feet plates should be coplanar within 0.05 mm? The next step is to set up the machines (for example a pump and motor) perfectly in line with each other, i.e., shaft alignment. And no, a straight edge and eyesight are not sufficient for the machines of today, as you understand!

Are you aware of dynamic forces?

Another thing often missed during machine installation are the dynamic forces generated when the machine is operational. They can be caused by pumped fluids, resulting in unwanted forces in pipe connections, or material expansion due to rising temperatures. This misplaces shafts, which in turn generate larger forces in bearings and sealings than the machine was designed for. An example from reality is a company that for many years never got one of their machines to work. Several so-called experts had been there and “proven” what was wrong, but the problems did not go away. With a quick dynamic movement check, we could show that the machine moved 1.3 mm horizontally after being started, which of course was devastating, and totally unexpected. With the right actions, the machine now finally runs as it should.

A laser alignment system quickly pays for itself

The great benefits of laser alignment systems are:

- Programs guide you step-by-step, which makes for ease-of-use.

- Versatile and quick to mount on most machine types.

- Highest reliability and precision (down to 0.001 mm).

Another great advantage with laser alignment systems is that you can document the work in a measurement report for you and the client, which shows that what has been done is within the tolerances required by the machine manufacturer.

In the longer term, this traceability is very important, as if constant problems arise in production, you can go back and see that the conditions were correct from the start. Or not. Then you know where to start problem-solving!

Even better is of course to do things right from the beginning – to give the machines the correct prerequisites for problem-free operation and optimum service life. The investment cost of a laser system is only a fraction of the costs for unplanned downtime and unnecessary high electrical bills. Increased competitiveness comes for free.

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

7 Reasons Why Machines Need Laser Shaft Alignment Technology

by Diana Pereda

When the beverage industry started to market its products in aluminum cans, a new by-product for industrial maintenance was created— soda and beer cans were sometimes used as shimming material for electric motors. Aluminum cans were flattened out and a slot cut into them to allow the shim to fit under the foot of the motor and accommodate the hold-down bolt. Of course, they only came in one thickness and the flattened pieces were not very even. Unfortunately, we came across such crude contrivances quite often.

Accurate machine adjustment is an essential element in any alignment process and a good-quality shim is a must. So… how to select a good quality shim?

- Use only slotted Precut Stainless Steel Shims since they eliminate material waste, time-consuming hand-cutting and deburring, and for heavy gauge shims the need to torch cut and mill.

- Stainless Steel 304, Monel, or other full hard materials protect against rust and deformation.

- Stock different precut shim sizes (A, B, C & D) for the correct fit on all motors and generators in accordance with their frame size.

- Shims should be etched (not stamped or inked) with thickness and size to facilitate identification and re-use.

- Thirteen standard shim thicknesses allow all possible shim change combinations up to 150 mils thick with just 3 shims, so make sure you always have all thirteen thicknesses on hand; this will actually save you money and prevent a “squishy foot” soft foot from too many shims under a foot!

- Always mike all shims 50 mils and thicker. These, while flat and even in their thickness throughout, may not necessarily be of the exact thickness marked on the shim, since these thicker thicknesses are always nominal and not exact.

Download our precut SS shims price list.

by Ana Maria Delgado, CRL

All rotating machinery is installed in trains. Trains mean there is a driver, the motor, and driven, which can be a pump, blower, compressor, or any other type of process machine. During the installation of rotating machinery, precision shaft alignment is performed. The shaft alignment will ensure that both shafts (driver and driven) are collinear. Collinear means that both rotational centerlines are positioned as if they were one.

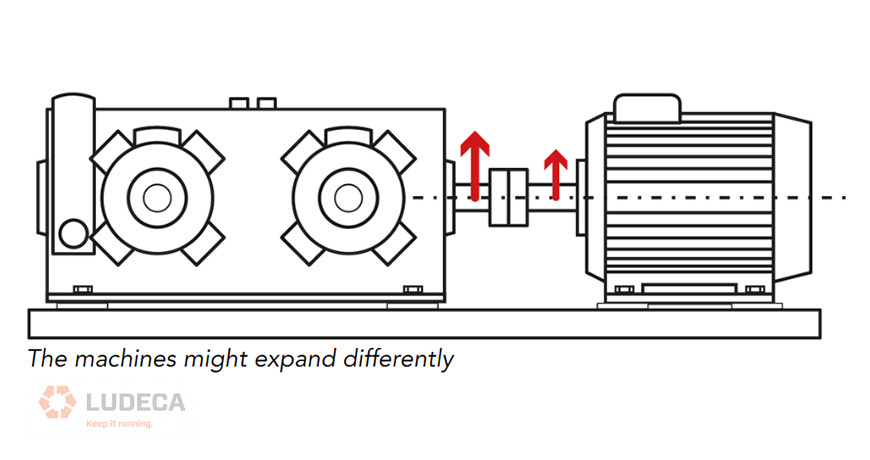

The effect of heat on driver vs. driven

When the machines are started, the driver and driven heat up in very different ways. A compressor in a hot environment will quickly increase in temperature due to friction of its internal rotating parts, and compression of the media will generate and add more heat. Comparing to the driver, which can be an electrical motor, the situation is very different. The temperature will increase to a certain level and then remain the same — two machines with two different behaviors.

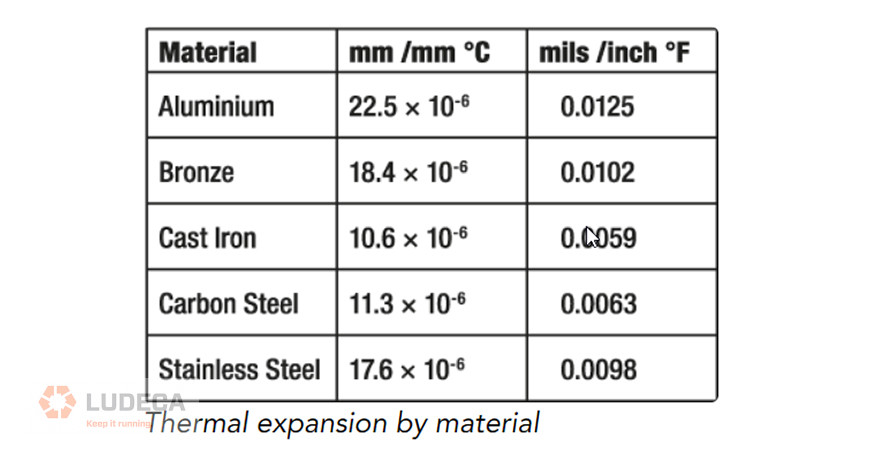

So, what happens when one of them increases its temperature relative to the other? It’s simple; the machine will start expanding. And when the machine expands, it will grow in all directions, move its rotational center out of collinearity and cause misalignment. But not only misalignment. Since there is a change in the machine geometry, pipe strain might also add more stress to the housing.

Take thermal growth into account from the start

There are so many consequences of thermal growth in rotating equipment. Misalignment will, for example, also result in a bent shaft. Bent shaft will result in improper distribution of forces in the bearing, which will lead to failure of the lubrication. Therefore, we must be able to anticipate thermal growth by using available information from the OEM, or by performing the calculation by ourselves. So how do we do that?

The key is to identify how much growth to expect. This number must be used when performing the shaft alignment to “intentionally misalign” the machines prior to start. Let us use the compressor as an example again. If we assume that the compressor will operate at a higher temperature than the motor, when aligning, we must place the compressor below the rotational centerline of the motor. How much below will be determined by the expected thermal expansion growth of the material.

Final test run

When the machine is aligned with the thermal growth considered, it must run and operate until it reaches its full operating condition. Then it must be stopped, and the shaft alignment verified. This is our test run of the machine, to confirm a proper and reliable installation, and to achieve full operational life. We want to test before we go to full production to ensure our thermal expansion calculation was correct.

Think about aircraft maintenance. When there is an aircraft engine replacement, the pilots perform test flights until it can be confirmed that everything is operating as it should. And you don’t want to be on the plane knowing nobody performed the test run, do you?

Watch our Shaft Alignment Know-How: Thermal Growth video to learn the importance of accounting for thermal growth on rotating equipment.

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

Thermal Growth in Alignment Components: Achieve Reliable Results With These 4 Tips

by Diana Pereda

In industrial facilities, the efficient operation of condensate pumps is crucial for maintaining production processes and avoiding costly downtime. Proper alignment is a crucial aspect in maintaining the performance of these pumps, with vertical alignment playing a critical role.

When aligning a vertical condensate pump, there are several key considerations to keep in mind. Here are a few:

- Shaft Alignment: The alignment of the pump and motor shafts is crucial for ensuring smooth operation and preventing excessive wear and tear on the components. Any misalignment can lead to increased vibration and potentially cause premature pump or motor failure.

- Base Plate Flatness: The base plate on which the pump is mounted must be level and flat to provide a stable foundation for the pump. A distorted or uneven base plate can cause misalignment and compromise the performance of the pump.

- Pump Shaft Bearings: Condensate pumps are typically assembled and bored in one operation to ensure bearing alignment. The pump components should be marked and pinned prior to bearing and pump shaft inspection to prevent misalignment during reassembling as the components may not be properly indexed to each other.

- Coupling Consideration: A condensate pump usually has a rigid type of coupling that supports the pump shaft. The coupling must be disengaged and the pump shaft should be centered to the bearing housing. The shaft alignment should then be checked between the static pump shaft and the rotatable motor shaft. If the coupling is flexible (such as a gear-type coupling as shown below), the measurement can continue using alignment methods that involve rotating both shafts.

By considering these best practices, you can ensure the optimal performance and longevity of your vertical condensate pump. Regular maintenance and alignment checks can also help maintain performance and prevent costly downtime.

Laser Alignment for a Vertical Water Pump with Easy-Laser XT

by Diana Pereda

It’s time to talk about torque! This topic is one of the most neglected aspects of Machine Maintenance. Equipment is designed to perform tasks reliably and efficiently. This can be accomplished if the machine is used as intended, and maintenance performed according to the specifications established by the manufacturer of the machine. There are always adjustments needed to accommodate local conditions, but those adjustments rarely mean making changes to specifications such as torque. If that specification is not adhered to, performance and reliability can suffer.

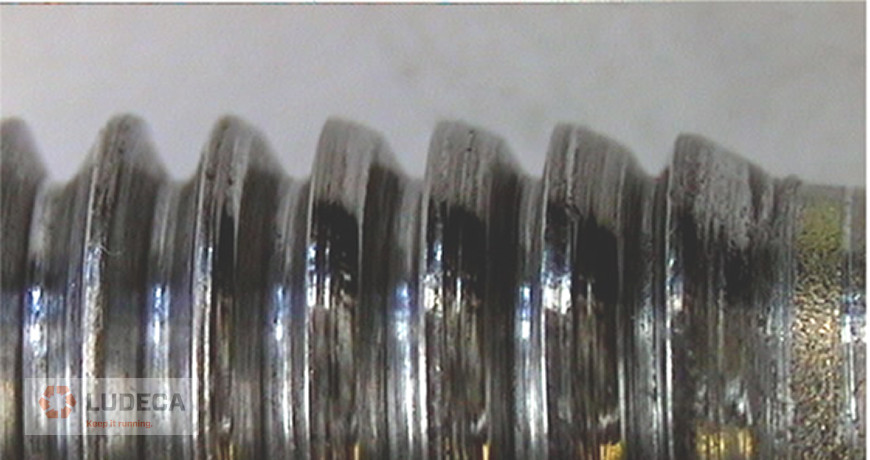

First, let us talk about what torque is. In a normal situation, the rotational force is applied to turning a fastener to achieve a specific clamping force. We are turning the nut or bolt until the resistance to that turning action reaches a certain point. After that point, we are stretching that joint into what is called the “elastic” working load range for that fastener. If this has been done correctly, the fastener should return to its pre-stretched length if the force is removed. In a case where that stretch does not go away, we have trespassed into the “plasticized” range for that fastener, and it can no longer create the clamping force needed for that joint. If you have ever felt a bolt have a lot of resistance to being turned, then all of a sudden it becomes easier to turn, you just went into that “plasticized” zone (provided you have not stripped the threads), and the bolt is now being stretched beyond its design parameters.

A common way to protect the integrity of a clamped joint is to simply use a longer fastener. The normal equation for grip length is to have 12 times the diameter of the fastener in length, to allow for the correct stretch but comfortably work within the “elastic” working range. (By the way, another minimum parameter to look out for is that at least three (but preferably five) threads engage in the joint.

Now that we have established that we need to achieve a correct clamping force, stayed tuned for Part 2 where I discuss how to get there!

Precision Maintenance: The Torque Wrench. Check Out These 15 Helpful Tips!

by Diana Pereda

Well-lubricated and properly aligned machinery are integral to the smooth running and continual functioning of your equipment and overall facility. Shaft alignment of rotating equipment is particularly important, as the unnecessary stress produced by misalignment will cause unexpected and costly downtime.

Poor vertical and horizontal pump alignment damages your equipment’s seals and couplings, which have been proven to cause lubricant leakages and consumption problems. Although you may think replacing the seals is a more affordable fix, seal failure, and lubricant loss is inevitable without addressing the cause.

Before we delve into vertical and horizontal pump shaft misalignment, let’s take a look at the problems caused by misalignment:

- Increased vibration and noise

- Premature coupling, shaft, and foundation bolt failure

- Excessive and costly seal lubricant leakage

- Premature failure of bearings and seals caused by excessive wear

- Increased friction which causes excessive wear, energy consumption, and possible premature equipment failure

To prevent these issues and make sure your equipment is running at peak efficiency, it is recommended the pump shafts need to be aligned in horizontal and vertical planes using laser shaft alignment equipment. When these shafts are misaligned, it can be due to parallel or angular misalignment – or likely a combination of both.

Parallel Misalignment

Parallel misalignment occurs when both shafts’ centerlines are parallel to one another in an offset way. It can be divided into poor vertical and horizontal pump shaft alignment.

Parallel Horizontal Pump Shaft Misalignment: In this case, your pump shafts are misaligned in the horizontal plane. The motor shaft has moved away from the pump shaft horizontally. However, both shafts are still operating in the same horizontal plane and are parallel.

Parallel Vertical Pump Shaft Misalignment: This refers to shaft misalignment in the vertical plane. Similarly, this means that the motor shaft has moved vertically away from the pump shaft, with both shafts operating parallel and on the vertical plane.

Angular Misalignment

Angular misalignment can also be divided into poor vertical and horizontal pump shaft alignment. This is when the motor shaft is at an angle with the pump shaft.

Angular Horizontal Pump Shaft Misalignment: Here, the motor shaft is operating at an angle to the pump shaft while operating in the same horizontal plane.

Angular Vertical Pump Shaft Misalignment: Again, your motor shaft and pump shaft are at an angle to one another and operating in the vertical plane.

Download our 5-Step Shaft Alignment Procedure a simple and effective procedure for shaft alignment of rotating equipment.

Thank you John Lambert with Benchmark PDM for sharing this blog with us!

by Diana Pereda

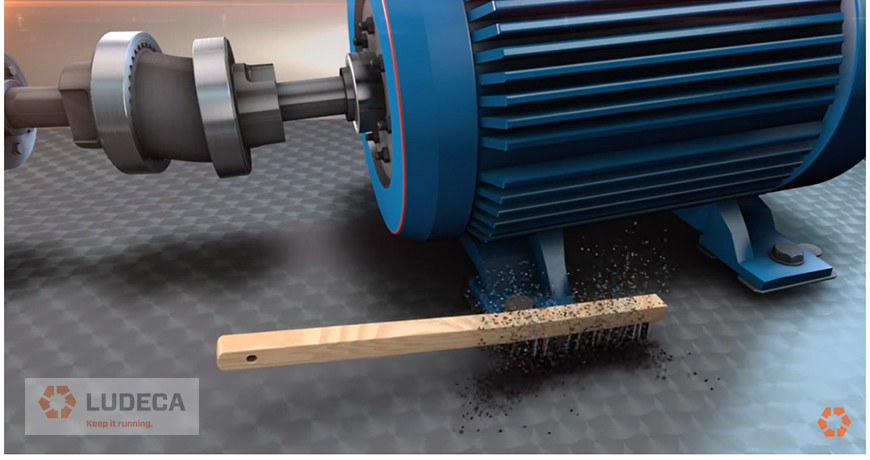

Before going on a trip, we typically plan ahead, what we’re doing and where we are going each day on the trip, and we pack accordingly. When starting an alignment job, it is not that different. Whether it means thoroughly cleaning the mounting base, having the right tools for the job, or allocating the right amount of hours, preparation can go a long way. Cleaning underneath the feet of the machinery will greatly decrease the chances of having a soft foot, thus increasing the machine’s ability to respond accurately to corrections. Also, check under the entire machine for loose debris. This might cause a soft foot as the machine comes down during alignment corrections, even though the feet of the machine are spotless.

Another thing that should be considered during pre-alignment, is to have the right set of shims. These must be the right size for your application, corrosion-proof, and made from high-strength material. They should also be free from burrs, bumps, nicks, and dents of any kind. Of course, tagging out/locking out the power of the machinery is the VERY first step before starting the alignment process. Having trained personnel can also cut down the hours it takes to perform the alignment.

Learn more about our precut SS shims.

Pre-Alignment Planning and Execution Steps for Rotating Machinery

by Adam Stredel CRL

Two new hires called into our office for help with an alignment they were doing with a newly bought Easy-Laser XT laser shaft alignment system. Fortunately, our chief engineer was able to remotely guide them through two successful gearbox-motor alignments. There was still an issue: these gentlemen were inexperienced and being tasked with aligning 20 additional similar setups for cooling towers, in peak Texas heat. The first alignment revealed that our motor, Machine To Be Moved (MTBM) was both base- and bolt-bound. The second alignment also found the motor to be both base- and bolt-bound. Every single cooling tower had identical gearboxes and identical motors that sat on identical “frames”. By the third alignment, a clear pattern formed. This was no coincidence, the jackshafts were 110 inches long, with machines that weren’t centered prior to installation. Small amounts of angular misalignment at the gearbox are enough to cause a bolt- and base-bound condition as the offset produced by the angularity is magnified across the long distance of the jackshaft’s length, making the resulting correction to be performed too large at the motor. An angularity of 0.5 mils/inch is enough to cause a 55-mil offset between the machine shafts at a 110″ separation. It is apparent that it doesn’t take much angle to run out of space in the anchor bolt holes at the motor. The motor sat higher than the gearbox while both machines sat angled slightly downwards, looking towards the center between them.

After realizing they were bolt-bound many experienced alignment technicians would elect to use “Chicago” bolts or undercut bolts, which are designed to allow for a little additional freedom of horizontal movement of the machine. Obtaining them likely would waste several hours, even with a machine shop on site. Another approach is to drill bigger holes in the feet. However, our two junior aligners saved on what could have amounted to several days over the course of all 20 alignments by instead performing optimal moves. An “optimal” move is a small adjustment made to the Stationary Machine (the gearbox in this case) that eliminates the need for the large projected corrections at the Motor. It is the smallest feasible move that will accomplish this objective. In these cases, both front feet were brought up, which is easy to do, since adding shims is always easier than removing them if they aren’t there to start with! This saves time and is generally the most efficient approach to the base-bound situation. In this case, the gearbox was free to move, no piping or another machine coupled to it, so it was a no-brainer. Undercutting bolts is popular because piping and electrical conduit along with other factors make it difficult and, in some cases, impossible to move one of the machines. In any case, an optimal move is worth considering at the very least. As long as your stationary machine is able to make the SMALL move necessary you will save yourself time. Very little risk considering it, bountiful rewards if it makes sense. It is up to the technician to use their judgement and experience to determine if this is possible and worth the effort.

The third alignment needed two vertical moves to get it within Precision (ANSI/ASA S2.75-2017) Tolerance. The first correction was to shim both gearbox and motor front feet up, this got rid of the base-bound condition at the motor. The second move was to shim all four motor feet up. One horizontal move was necessary via gearbox to get out of bolt-bound condition, no jackbolts on the machine so a hammer was used. Every setup was the same, allowing our junior aligners to employ the template feature of their XT laser system and save more time there as well.

by Ana Maria Delgado, CRL

At times, shaft alignment can become extremely frustrating almost as if it is possessed with a mind of its own. One set of readings may indicate that you make adjustments one way, the next set of readings then indicates something completely different. Quite simply, and almost without fail, if there are repeatability issues then something is loose with the laser alignment tool or there is some mechanical play.

Assessing Detector Movement

Here are some simple questions to work through to try and diagnose and address issues with looseness:

- Are the chain brackets tight to the shaft or hub?

- Are the detectors tight to the rods?

- Are the extension rods tight to the brackets?

- Is the sensor rubbing on something when positioning the shaft?

- When using magnetic brackets, do the magnets have full contact to prevent them from slipping?

- Did you bump something out of place?

Assessing Coupling / Bearing Play

Here are some simple questions to work through to try and diagnose and address issues with mechanical looseness or play:

- Are all the hold-down bolts on all pieces of equipment tight?

- If it is mounted to a hub instead of the shaft, is the hub tight to the shaft?

- For sleeve bearings, has the shaft come to rest so you know for sure it’s in the same spot for measuring?

- Is there coupling play or backlash?

- Is there any bearing play?

- For all the above, did you double check and are you sure?

Other Diagnostic Factors to Consider

There may still be base or foot movement that is causing looseness or it could be a torsional movement issue. Simply, you will be able to tell by addressing the operation of the machine to ascertain:

- If the feet are moving relative to the base

- If the base is moving relative to the feet

- If there is debris around the shims and base

- If multiple shims can be consolidated

Torsional movement addresses looseness in the coupling, whether it is being controlled in a consistent manner if the backlash in the gearing is being controlled, and if the chain or magnetic brackets are fitted tight to the shaft or hub.

Thanks to our colleagues at BENCHMARK PDM for sharing this blog with us!

by Ana Maria Delgado, CRL

Because of my many years of experience in the field of installation and maintenance of rotating equipment, I can say that installation is a fundamental thing. But why is this phase so important?

Well, because the installation has a direct impact on the machinery, and will determine operating conditions, performance, and life cycle cost. Basically, the way you install your rotating equipment is the way it will perform. And personally, I always ask myself why companies buy million-dollar pieces of equipment and let inexperienced installers do the installation. Then, they spend another million dollars on condition monitoring watching them fail.

Don’t get me wrong; condition monitoring is extremely important to understand what is happening to the machines and detect an early failure. But the fact is that most of the failures occur due to poor installation and design. Here, let’s focus on the installation phase of rotating machinery.

What do we expect from our machinery?

- Reliable operation – We expect our rotating equipment to deliver its intended purpose or service without failure.

- High performance – We expect our equipment to perform as per design.

- Long service life – If our equipment has been designed for 20 or 30 years of operation, that is what we want to achieve.

- Low maintenance cost – We expect not to spend any additional money after the investment has been made.

Responsibilities towards the installation

Communication, Procedures, and Integrity. These are responsibilities that are so important in the installation phase. Let me explain:

Communication

It is a must to assure proper communication among the Design, Engineering, and Installation teams. We know there are constant challenges to keep the installation work to be on time and within specifications. The teams must have constant communication to be able to solve any difficulties or changes. In the real world, not everything fits as it fits on the drawings. I think many of you have experienced this, right?

Procedures

Installation procedures must be created according to design specifications and every member of the team must be familiar with them. Depending on which industry, the procedures will differ from each other. It is not the same thing to perform the installation in the nuclear plant compared to the pharmaceutical industry. There should always be a reference to which specific standard belong to the site where the installation is taking place. API Recommended Practices for Machinery Installation and Installation Design (API 686) are the perfect foundation to start with.

Integrity

Integrity is an important part of the installation phase and it starts with Safety. Everyone who participates in the installation must go through safety training. Specific trainings must be performed such as working in heights, confined spaces, fire protection, or chemical handling. Breaking the safety rules will put the project behind the schedule therefore it is very important to follow them.

Always do things in the right order

The installation of rotating equipment must follow a certain order. The order of the installation procedure is designed to always start from the base. Foundations are the cornerstone of the entire installation. They are designed to hold rotating machinery and transfer and dissipate stresses and dynamic forces produced by pulsations and processes. Therefore, special attention must be paid to the foundations. They must be flat, coplanar, and levelled. If we skip the order of the installation procedures, we will not be able to complete further steps and not achieve reliable operation of our rotating equipment.

Finally, all the work must be properly documented during the process by creating digital reports to be able to review and compare the values and data. This is important for the references because further work will depend on the results.

Thank you Roman Megela with Easy-Laser for sharing this informative article with us!

Download our 5 Elements Machine Installation infographic which outlines 5 important elements of machine installation including Foundation, Anchoring, Isolation, Baseplate Level and Flat plus Alignment.

by Diana Pereda

MYTH: “You should always do your shimming first and then make your horizontal moves.”

TRUTH: This is generally true for the final alignment after soft foot has been corrected, but is not universally true for all alignments. In fact, for the initial rough alignment, you should correct the plane with the largest misalignment first, even if this means making a horizontal move first. Reason: If you have gross misalignment, you could be binding the coupling, deflecting the shafts, and imposing undue load on the bearings. By relieving strain from excess misalignment, a truer picture of the alignment condition emerges, and you eliminate an important outside force that creates machine frame distortion (soft foot).

Therefore, the correct sequence of events in any alignment job is:

- Safety: Lockout & tag out plus clean up

- Rough Align

- Find, diagnose, and eliminate Soft Foot.

- Final Alignment: shimming first, then moves.

Download our 5-Step Shaft Alignment Procedure a simple and effective procedure for shaft alignment of rotating equipment.

by Diana Pereda

There has been a lot of improvement because of the laser shaft alignment and laser geometric alignment systems. They help you to identify the failures in your machinery and eliminate them easily. That’s why it is always critical to make necessary alignment activities to keep your equipment working stably and consistently with accuracy, less effort, and less training. We can also use straight edge method for rough coupling and alignment or otherwise reverse indicator method which is sometimes affected by obstacles like vibration effects which can be used when the technician is experienced enough to know exactly what he is doing for accurate results. However, these methods are not as efficient and accurate as the use of the laser is.

The major types of misalignment are the offset and angular misalignment. The laser alignment is definitely faster and cost-effective but the use of this technique needs some training for good outcomes.

There are couple of very common phenomenon that occur while working in the workshops and they are:

- Thermal growth in which some parts of the machines suffer expansion because of the over-running or heating mechanism which causes the problems of misalignment because of the change in relative positions of the parts due to the growth in the machine parts.

- The secondary cause of the misalignment is soft foot which causes the distortion in the frames of the machines that are coupled directly to each other.

Now there are some steps that you can take to resolve these alignment issues. The first step is to lock out and tag out the machines to work for safety. Then you should clean the area around the machine feed. In the end, check for soft foot and then align the machines properly and recheck them if needed for surety. You should also document these problems that you found and resolving methods for specific issues according to ISO 9000. Preventative maintenance is always better for which your bases should be strong to avoid any soft foot failures in the first place. At best, what you can do is to buy the laser alignment equipment from the best vendors who can work with you when you need them and give the workers some training for best results.

You should always check for failures and correct them on a regular basis to make sure it’s the perfect alignment for longevity. Implementing a complete formal alignment procedure is always an edge in the field of reliability and maintenance.

Hear more from Alan Luedeking in this podcast by James Kovacevic to know where to start with precision maintenance and how to keep your equipment aligned to avoid common problems so you can increase productivity and efficiency.

5 Things You Need To Implement A Precision Maintenance Program

by Diana Pereda