Reposted from EASY-LASER® blog

Are you the type of person who, going by the principle of “We’ve always done it this way, and it’s worked well”, continues to use a ruler or a piece of string to align your sheaves/pulleys? If so, you can definitely save some money, by reading this.

It is a common misconception that it doesn’t matter whether you align your pulleys or not. The belt is flexible, and can handle it, right? And if a belt or sheave becomes worn, it is easy to just replace it. But what you might not be considering is that the cost of energy is greater than the cost of buying new spare parts such as bearings, belts and pulleys. Studies have shown that with correct alignment it is possible to improve the efficiency of your belt drive saving you from 5 to 20% of your energy costs. This can quickly add up to significant amounts, particularly if your enterprise has tens or even hundreds of belt-driven machines.

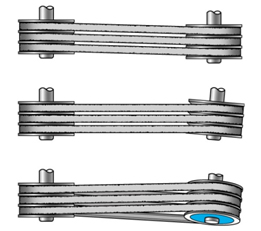

CONSEQUENCES OF GOOD AND POOR BELT ALIGNMENT

Poor alignment or incorrect installation are the most common causes of abnormal wear of sheaves and pulleys. On the other hand, increased productivity, fewer unplanned operational stoppages and reduced energy consumption are the result of well-aligned machines. In the long run, this is also positive for the environment. By aligning your belt-driven machines, you also reduce vibration that harms the machine and adversely affects the working environment.

One consequence of poorly aligned belt drives that is often overlooked is that incorrectly aligned or improperly tensioned belts can result in abnormal temperatures, caused by the belt’s friction against the pulley. Excessively high temperatures will cause the belts to harden, resulting in cracking. A toothed belt can lose teeth, leading to slipping and efficiency loss. Strong heat sources in the vicinity also affect belts negatively. A thermal camera can help to indicate potential abnormal temperatures.

WHERE DO I START?

Many belt manufacturers advocate preventive maintenance in order to avoid unforeseen stoppages. A scheduled operational stoppage is obviously more efficient and less costly than an emergency repair on a failed drive. However, having a maintenance program for your belt drives can also be efficient. There are a number of factors that determine how often you should perform preventive maintenance. Start by classifying your machines in these ways:

- How critical the machines are for your operation.

- The rotational speed of the machine.

- The drive’s impact on the environment.

- The current status of the drive (i.e., condition/quality of the belts and pulleys.)

When you have done this, you will be in a better position to know how to prioritize your maintenance work.

You should also think about the following:

- First and foremost, it is worth thinking about keeping the area around the machine free of dirt and debris, and ensuring that the base is in good condition.

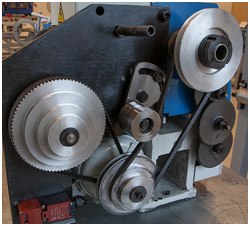

- It is important for the person carrying out the maintenance to have the correct training and equipment to carry out the work satisfactorily. A laser pulley alignment tool is highly recommended.

- Check the machine manufacturer’s specifications regarding how to set up your machine correctly. Write this down so that it is easily accessible the next time maintenance is to be performed. This saves time.

- Check the belt manufacturer’s suggested belt tension values. A spring gauge to measure belt tension is an essential item in the aligner’s toolkit.

- Mixing different belt types or brands is not recommended.

- If the transmission has several belts abreast, all the belts should be replaced together, even if only one is found to be defective.

- Measuring energy consumption before and after alignment is a simple way of verifying that you are now saving money.

- Listen to and look at the machine. If you suspect that anything is abnormal, you should investigate this. You should look out for unusual and abnormal wear or damage.

- Inspections should be performed frequently, perhaps as often as once a month.

- In addition, preventive maintenance should be performed at 6 to 12-month intervals.

- Follow the belt manufacturer’s instructions when replacing belts. Make sure that you also store belts correctly: don’t hang them, coil them flat! (Belts are a perishable product!)

Click here for examples of how much you can save by having your belt drives correctly aligned.

If you are ready to start improving the efficiency of your belts and sheaves, find the tool that best fits your needs.

Filed under:

Alignment, Maintenance Tips by Yolanda Lopez