In our previous blog, we discussed the: Shaft Alignment Measurement Mode: Continuous Sweep Method. In this blog, we continue with the next method: Multi-Point.

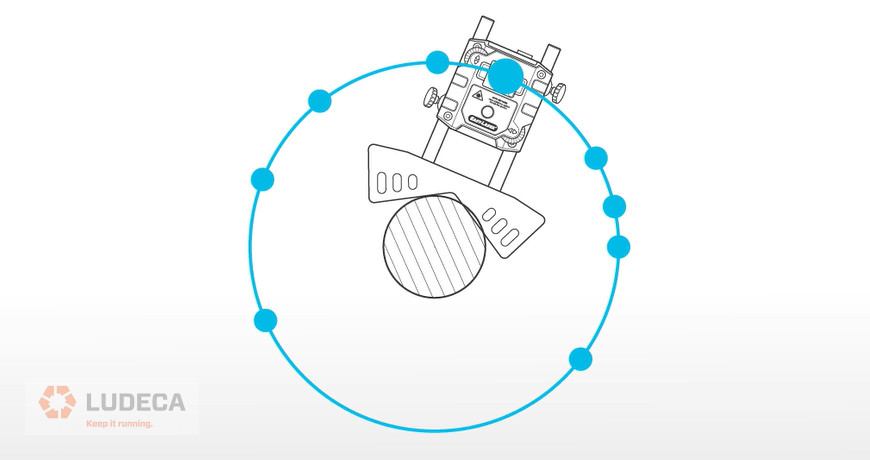

The Multi-Point measurement mode is among the most versatile measurement modes as it allows you to measure under any condition. It lets the user begin the measurement from any rotational position and take as many points as necessary to achieve excellent measurement quality every time. The points can be taken at any rotational position and can be as close together as 1 degree apart. A minimum of three measurement points is required, well distributed around the shafts to obtain accurate results. This measurement mode is designed for the Easy-Laser XT550, XT660, & XT770. Below are some examples:

-

Easy-to-rotate machines

- For machines that are easy to rotate, take a minimum of three points spaced approximately 120 degrees apart to cover a full rotation of the shafts evenly. However, taking more points is always better as it gives the system more data to work with.

-

Difficult to rotate machines

- For machines that are very difficult to rotate, the forces required to rotate the shafts may induce shaft deflection. Using Multi-Point we can relieve the rotational force and let the machine rest with each point taken, thereby avoiding shaft deflections completely.

-

Uncoupled measurement

- For uncoupled machines, trying to rotate both shafts together is next to impossible. Using Multi-Point, we can use the OLED display on top of each Laser/detector unit to align both the S and the M measurement units to the same angle. This will simulate the machines being coupled and allow us to get as many points as needed without any difficulties.

-

High vibrations

- For environments with high vibration from surrounding running machines or processes, using the Multi-Point measure mode lets us use the filter located at the bottom of the measuring screen to compensate for this environmental vibration. The higher the filter value the higher the vibration that can be compensated for. Since the shafts are allowed to rest at each measurement position as long as necessary to achieve stable readings, inaccuracies are eliminated.

-

Limited rotation

- For machines with obstructions to rotation or to line-of-sight for the lasers, the Multi-Point measurement mode allows you to accurately measure misalignment with as little as 40 degrees of shaft rotation. Take as many points as possible within the small arc of rotation available to you and you will still obtain reliable misalignment readings.

Watch our Shaft Alignment Know-How: Why Alignment to learn the benefits of precision machinery alignment.

Filed under:

Alignment by Carlos Bienes CRL