Use ANSI Shaft Alignment Tolerances to help solve base-bound and bolt-bound situations. If a base- or bolt-bound situation presents itself during an alignment, take advantage of the outer limits of the tolerance envelope to help overcome the problem. It may be possible to optimally position the machine to meet the minimal ANSI tolerances and eliminate the bolt-bound situation altogether.

Say, for example, a machine is horizontally bolt-bound at the inboard feet. It is currently within precision angularity tolerance but is just shy of satisfying the offset tolerance. A possible solution for this is to try adjusting the offset by moving only the back feet and pivoting the machine about its front feet, thereby causing the offset to also fall within minimal tolerance, without compromising the angularity in the process. While this may cause the angularity to shift from precision to standard tolerance, this is perfectly acceptable so long as both the angularity and offset fall within ANSI Tolerances when you are finished. Some laser alignment systems even allow you to test the effect of proposed moves before you actually make them, thereby allowing you to determine if a proposed move such as the one described above will work before expending the time and effort actually trying it.

By evaluating the alignment situation objectively, and planning a move to remain within the tolerance limits of the alignment conditions, you can avoid unnecessary moves, machining, or hardware alterations to achieve the alignment. This will save you time and money!

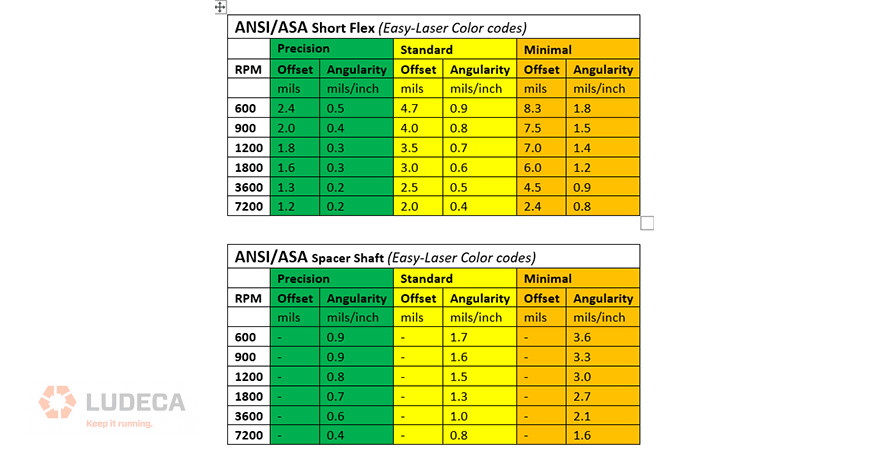

Below are the ANSI tolerance tables for both short-flex and spacer shafts:

Watch our Shaft Alignment Know-How: Bolt-Bound video and learn about the options of achieving alignment when in a bolt-bound or base-bound condition!

Filed under:

Alignment by Carlos Bienes CRL