Before going on a trip, we typically plan ahead. What we are going to do, what we are going to pack, where we are going to go, and places to visit each day of the trip. When starting an alignment job, it is not that different. We must plan ahead. This means being ready to thoroughly clean the mounting base, having the right tools for the job at hand, and allocating the necessary number of hours to get the job done right.

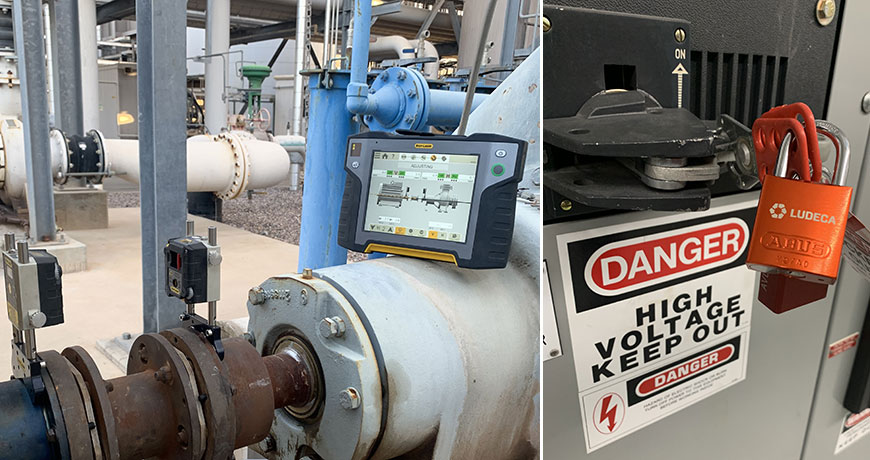

Proper preparation for success can go a long way. Cleaning underneath the feet of the machinery will greatly decrease the chances of having a soft foot, thereby increasing the machine’s ability to respond accurately to corrections. Also, check under the entire machine for loose debris. Foreign objects under the machine can cause soft foot as the machine is lowered during alignment corrections even though the feet of the machine and shim packs are spotless. Another thing that should be considered during pre-alignment is having the right set of shims. These must be the right size for your application, corrosion-proof, and made from high-strength material. They should also be free of burrs, bumps, nicks, and dents of any kind. But first and foremost is planning for safety. Locking out/tagging out the machines is the VERY first step before starting the alignment process. Getting the right training to operate your laser alignment system and understanding misalignment will also save time and ensure success.

Let’s summarize a few of these important planning and execution steps:

- Lock-out and tag-out

- Thoroughly clean the mounting base and feet

- Visually inspect for foundation, grout, and baseplate defects, and wear and tear

- Make sure to have the right tools for the job

- Make sure to have the right shims

- Inspect and replace damaged shims

- Allocate the right amount of hours

- Have the right training

- Make sure your high-quality laser alignment system, such as an Easy-Laser XT770, is charged and all components and needed accessories like specialty brackets are there.

Download our 5-Step Shaft Alignment Procedure for a simple and effective procedure for shaft alignment of rotating equipment!

Related Blog: Pre-Alignment Checks plus Essential Clean-up and Preparation Tasks

Filed under:

Alignment by Carlos Bienes CRL