It’s time to talk about torque! This topic is one of the most neglected aspects of Machine Maintenance. Equipment is designed to perform tasks reliably and efficiently. This can be accomplished if the machine is used as intended, and maintenance performed according to the specifications established by the manufacturer of the machine. There are always adjustments needed to accommodate local conditions, but those adjustments rarely mean making changes to specifications such as torque. If that specification is not adhered to, performance and reliability can suffer.

First, let us talk about what torque is. In a normal situation, the rotational force is applied to turning a fastener to achieve a specific clamping force. We are turning the nut or bolt until the resistance to that turning action reaches a certain point. After that point, we are stretching that joint into what is called the “elastic” working load range for that fastener. If this has been done correctly, the fastener should return to its pre-stretched length if the force is removed. In a case where that stretch does not go away, we have trespassed into the “plasticized” range for that fastener, and it can no longer create the clamping force needed for that joint. If you have ever felt a bolt have a lot of resistance to being turned, then all of a sudden it becomes easier to turn, you just went into that “plasticized” zone (provided you have not stripped the threads), and the bolt is now being stretched beyond its design parameters.

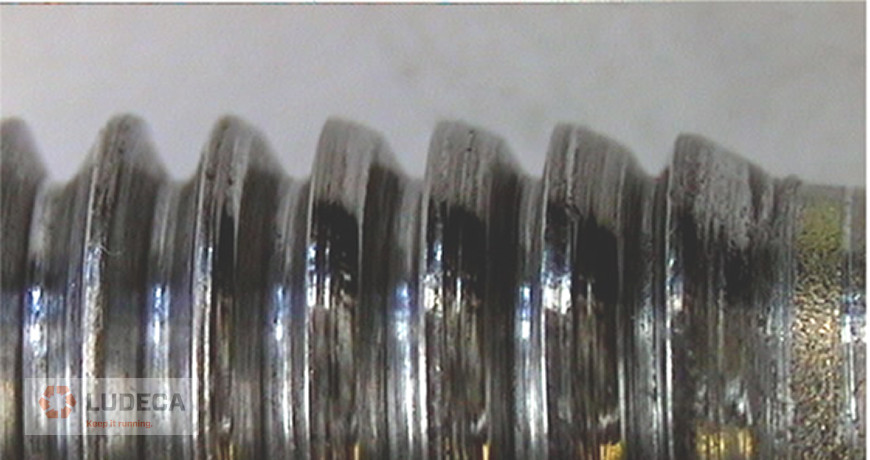

A common way to protect the integrity of a clamped joint is to simply use a longer fastener. The normal equation for grip length is to have 12 times the diameter of the fastener in length, to allow for the correct stretch but comfortably work within the “elastic” working range. (By the way, another minimum parameter to look out for is that at least three (but preferably five) threads engage in the joint.

Now that we have established that we need to achieve a correct clamping force, stayed tuned for Part 2 where I discuss how to get there!

Precision Maintenance: The Torque Wrench. Check Out These 15 Helpful Tips!

Filed under:

Alignment by Chris Greene CRL