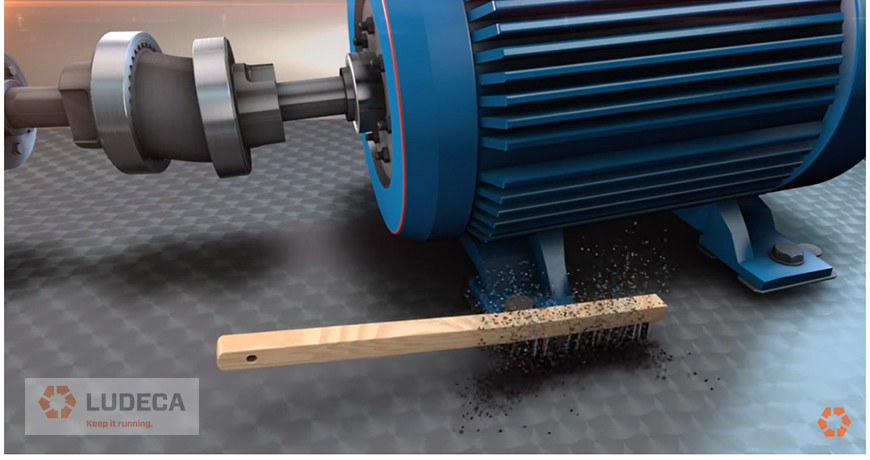

Before going on a trip, we typically plan ahead, what we’re doing and where we are going each day on the trip, and we pack accordingly. When starting an alignment job, it is not that different. Whether it means thoroughly cleaning the mounting base, having the right tools for the job, or allocating the right amount of hours, preparation can go a long way. Cleaning underneath the feet of the machinery will greatly decrease the chances of having a soft foot, thus increasing the machine’s ability to respond accurately to corrections. Also, check under the entire machine for loose debris. This might cause a soft foot as the machine comes down during alignment corrections, even though the feet of the machine are spotless.

Another thing that should be considered during pre-alignment, is to have the right set of shims. These must be the right size for your application, corrosion-proof, and made from high-strength material. They should also be free from burrs, bumps, nicks, and dents of any kind. Of course, tagging out/locking out the power of the machinery is the VERY first step before starting the alignment process. Having trained personnel can also cut down the hours it takes to perform the alignment.

Learn more about our precut SS shims.

Pre-Alignment Planning and Execution Steps for Rotating Machinery

Filed under:

Alignment by Adam Stredel CRL