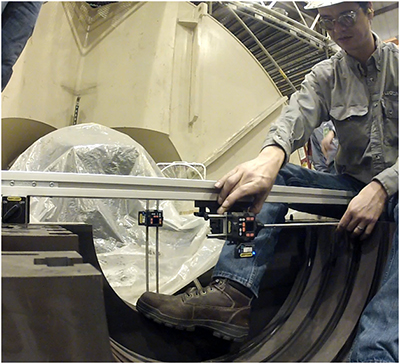

Steam turbine internal alignment applications require high precision, ease of use, and reliability. The Easy-Laser® E960 system is used to align diaphragms and internal components and delivers all these things.

Setup is fast and simple. There is no need to precisely center your detector to the bore or the laser to the rotor to perform position checks. Simply orient the sensor into laser range, and the display unit does the rest to calculate the center. Your rotor positions are entered digitally for greater accuracy and speed of setup. Wireless components streamline the setup—no cables to get in the way!

Setup is fast and simple. There is no need to precisely center your detector to the bore or the laser to the rotor to perform position checks. Simply orient the sensor into laser range, and the display unit does the rest to calculate the center. Your rotor positions are entered digitally for greater accuracy and speed of setup. Wireless components streamline the setup—no cables to get in the way!

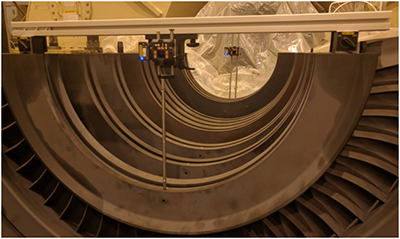

Take three points over 180 degrees on a bore just as you would with a tight wire, or use the multipoint measurement to find the center of bores and check for ovality.

The Easy-Laser E960 features an optional reference control sensor for greater reliability and precision. No more guessing whether your reference line (the laser beam), moved during measurement—you are in control of its position at all times. Even if the beam moves over time due to environmental factors, the reference control sensor allows the system to automatically adjust for such movement to ensure all your readings stay highly accurate.

Need to measure the flatness of the shell? Simply add the D22 rotating laser and flatness readings can be taken using the same sensor as the one you use for internal bore alignment. Both the top and bottom shells can be measured without having to remove the bolts.

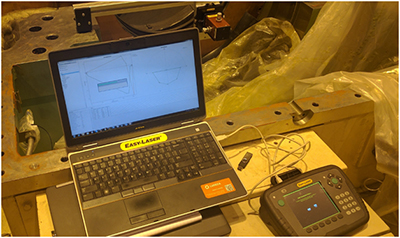

This system works with your existing processes. The Easy-Laser E960’s intuitive display allows for entry of diaphragm positions into your excel spreadsheets or takes advantage of the included Easy-Link software to present, process, and document the turbine alignment in one complete and easy to use package.

by Daus Studenberg CRL

Recently, I&E Central (along with a service partner) used the Easy-Laser E940 Machine Tool system to perform alignment on an automatic lathe similar to the photo above. The lathe has an automatic feeder for 20’ sections of tube stock which are supported alternately by V-rollers and then clamped by “steady rests” while being machined. The objective of this job was to have the stock in perfect alignment with the rotational center of the spindle when supported by either V-rollers or the steady-rests. In addition, there is a pusher system that advances the stock into the collet. The movement of the pusher needed also to be aligned with the spindle centerline. This was a challenging measurement made possible by the availability of a spindle laser that could be directed back through the collet.

Measurement Procedure:

A laser transmitter was mounted in the spindle with its beam directed through the collet. The laser was adjusted to the rotational centerline, then the spindle was turned at 200 RPM for measurement. In this way, the beam precisely marked the rotational center along the entire length of the machine.

The first measurement was the location of the center of each steady rest. A laser detector was mounted on a short piece of stock, which was locked in each steady rest for measurement. A center of circle straightness program was used to measure and adjust the position of each steady rest. These were adjusted “live” so that each steady rest held the stock in line with the spindle rotation.

Once completed, pk-pk deviation in the vertical plane was 0.0095”, in the horizontal plane it was 0.020”, well within the customer’s desired specifications.

The next step was measuring the straightness of travel of the pusher arm relative to the rotational center of the lathe. This was accomplished by grasping a similar piece of stock with the jaws of the pusher, then using the same program to measure and adjust its true position at 4 locations along its travel.

The final adjustment involved adjusting the V-rolls to support the tube stock in line with the center of rotation. This adjustment was actually done without the laser. A full-length piece of stock was secured in the collet with the other end supported by the pusher. Each V-roll in turn was adjusted with shims so that it supported the stock precisely on the centerline. The customer tells us that the machine now runs smoother than it ever has.

The measurement and alignment of this machine section were never performed by the customer or any service contractor in that they had no way to make the measurements. The power and flexibility of the Easy-Laser E940 system made this a straightforward job that was completed in 1 day.

Special thanks to Bob Dunn with I&E Central, Inc. for sharing this case study with us!

by Ana Maria Delgado, CRL

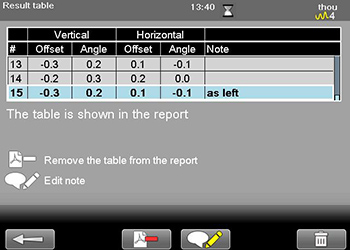

The new Easy-Laser 12.0 firmware now features a handy table that lets you instantly see how well your readings repeat and save comments for them. When performing laser shaft alignment it is a best practice to take two sets of readings immediately after system setup to establish repeatability. Bad repeatability can signal measurement problems such as loose or faulty components, brackets rubbing, backlash between shafts, loose bearings and other causes. The repeatability table lets you establish confidence in your readings before you proceed to carry out adjustments on the machines.

Hurry and upgrade your Easy-Laser E710 shaft alignment computer to this latest firmware. It’s free!

by Ana Maria Delgado, CRL

Reposted from EASY-LASER® blog

Engineering no doubt spends a lot of time deciding what machines should be specified and how best to set them up for optimal production. And you already know how important shaft alignment is. But there are other ways to make your machine perform even better and last longer. A careful base setup is key if you want to increase the machine’s lifespan and avoid unexpected downtime and other disturbances.

Why you should pay attention to the base setup?

Setting up the base properly is more important than many realize; it is crucial if you want to avoid unnecessary machine stress, and prevent costly problems in the long run.

First, the base has to be strong enough to support the weight of the machine. It also has to be able to withstand a large amount of torque and other loading that the machine produces. In addition, the base also needs to be flat and level.

An uneven or unleveled base can cause all kinds of issues for you: shaft misalignment, pipe strain, distorted machine frames (soft foot), etc. Even a small defect can have significant negative consequences on production.

The machine base – A great investment!

A base that’s flat and level will increase the machine’s lifespan and will save you unexpected downtime with costly repairs. You will also benefit from increased production time and greater efficiency of the machine with reduced energy consumption.

EASY-LASER E720 Alignment/GEO system

Don’t just eyeball the base to see if it’s flat. Use a laser. You might already be familiar with shaft alignment lasers. In this case, you need another kind of measuring tool, such as the Easy-Laser E720 system. The point laser will allow you to optimize both base flatness and shaft alignment. The Easy-Laser D22 (swiveling laser) will help you level the base. No other system on the market offers this type of flexibility.

by Ana Maria Delgado, CRL

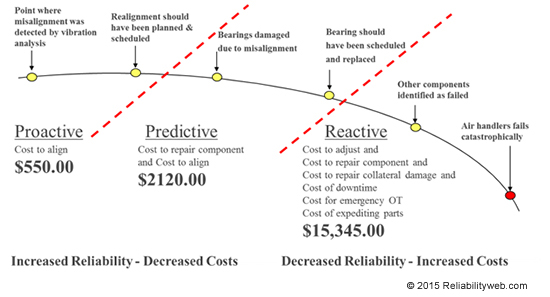

The Potential to Failure Curve (or P-F Curve) gives the user information on how an asset behaves before a failure occurs. This example is focused on failure due to misalignment. The goal of a reliability-focused plant is to be as far to the left on the curve as possible. While some companies are doing predictive maintenance work in an effort to reach the left side, many companies today are on the right domain of the curve, doing reactive work. Being in the reactive domain—putting out fires as they say— increases maintenance costs. This forces a company to perform unplanned work causes unscheduled downtime, and higher costs to expedite parts. Using technologies like ultrasound, thermography, and vibration analysis will catch an asset in a pre-failing state. This allows time to plan and schedule the repair to take place. However, with the right processes in place, the technician should recognize the misalignment of the machine before it causes components to fail. The ultimate goal is to be so far left on the curve, that it is off the chart, at the point where all the efforts (flat and rigid bases, accounting for thermal growth, eliminating soft foot, precision alignment, etc) are made so that the machine never runs misaligned.

by Adam Stredel CRL

Reposted from EASY-LASER®

There are many consequences resulting from having a poorly functioning measurement and alignment system. If there is any uncertainty concerning your laser system’s functionality, the measurement and alignment process could take longer than necessary. If the system isn’t in perfect working condition you might need to double-check your results more than once. The wrong alignment of the production equipment caused by incorrect measurements can lead to problems with the machines, as well as compromised product quality. Check calibration of your laser system at the recommended intervals or sooner to guarantee good alignment, peace of mind, and ensure that you always have the latest firmware version installed.

by Ana Maria Delgado, CRL

It can be argued that lubricants are the lifeblood of equipment. It is extremely difficult to assure equipment reliability when lubrication integrity is not maintained. The key is to keep the lubrication system clean, cool, and dry.

According to the Arrhenius Rate Rule, every 18-degree (F) increase in oil temperature in operation reduces oil life by half. Excessive lubrication temperatures can lead to additive depletion, oxidation, varnishing, hazards, corrosion, increased frequency of oil changes, and more. All of this leads to reduced equipment reliability and increased costs.

Reduced operating temperature is one of the many benefits associated with proper machinery alignment. This in turn will help you reduce the operating temperature of the lubricants (lifeblood) within your equipment. Best practice equipment reliability includes proper equipment alignment. Your best practice lubrication efforts should include making sure your equipment is operated within proper alignment tolerances. Doing so will help you maintain the “cool” required to ensure that the lifeblood of your equipment is protected.

by Trent Phillips CRL CMRP - Novelis

Problem: The machine shop of the engineering department of a prestigious Florida university wanted to identify the source of error in their tool room lathe. They had previously observed that when working pieces further away from the spindle chuck, there was an appreciable deviation in accuracy compared with close-to-the-spindle work.

The machine shop instructor suspected the problem to lie somewhere in the tailstock and asked us to confirm or refute his suspicions.

Solution: The Easy-Laser E940 Machine Tool laser alignment system was used to perform three types of measurements:

- Z-axis straightness measurement

- A spindle direction measurement

- A spindle-to-tailstock alignment measurement

In addition, the Values program was used to check for play in the tailstock sub-spindle bearings. An additional check was performed to verify whether the tool support returned to its original position when it was unlocked, and then locked again.

After accomplishing the above measurements and checks, it was determined that the straightness of the Z-axis was within tolerance, the spindle direction was ascertained and the alignment between the spindle and tailstock at the furthest distance revealed a small angle. There was no significant play in the sub-spindle bearings and the tool support check was good.

This data allowed the instructor to narrow down the possible corrective actions to take in order to achieve a better alignment and return the lathe to an optimum performance condition.

The ability to perform all of these checks and measurements to a high degree of accuracy allowed the university to quickly and more certainly identify worn components, which will save them a great deal of money in spares costs, as well as ensure that parts and workpieces fabricated on this lathe will turn out as expected, on time and within design tolerances.

by Oliver Gibbs CRL

May 2016 · Plant Services Magazine

Like a lot of reliability engineers, Joe Anderson, former reliability manager at the J.M. Smucker Co., appreciated – in theory – that precise pulley alignment is critical to preventing vibration problems and ensuring successful operations.

My understanding was, ‘Yeah, we need to do it,’ ” Anderson says. “But you always have these excuses.”

When the Smucker’s plant at which Anderson worked launched a dedicated vibration monitoring and control program a year-and-a-half ago, though, Anderson quickly became a convert to making precision alignment a priority.

The plant purchased a vibration analyzer (VIBXPERT®) and laser alignment tool (the SheaveMaster® Greenline) from Ludeca to help aid in identifying machine defects that appeared to be linked to vibration caused by misalignment. Laser alignment allowed for correcting vertical angularity, horizontal angularity, and axial offset – the three types of misalignment – simultaneously. Whoever was using the laser alignment tool, then, could be sure that adjustments made to correct one alignment problem didn’t create an issue on another plane.

Read the entire article to learn how J.M. Smucker Co. made precision alignment a priority: Get your alignment in line: Don’t jiggle while you work

by Ana Maria Delgado, CRL

There are many tools considered “accurate”. Dial test indicator can measure to the ten-thousandths and gauge blocks can be certified for even tighter tolerances. Even CNC machines can reach ten-thousandth’s accuracy given the right conditions. However, they are tools and they can’t perform to their maximum potential if not used properly or in the right application.

Laser shaft alignment tools follow the same rules. The sensors by themselves have varying degrees of accuracy but how the sensors are used and what application they are used for can vary this accuracy quite a bit. When searching for a “laser alignment system”, don’t be quick to commoditize the term and think all systems are the same just because it uses a “laser”. The most capable systems will work for their intended primary application— general shaft alignment. Should a specialized application arrive, such as an uncoupled spacer shaft with limited rotation, a system that has more functionality will be able to immediately handle the job over a basic system.

LUDECA can assist you in your decision. We provide a network of local solutions providers who are your highly experienced advisors for navigating all of the choices that a quick internet search can provide. They will make sure you know you are getting the right tool for your needs whatever your budget. We also have a team of engineers that will guide you in your applications. All this is provided for free! This is something to consider when purchasing on price alone. We will be there when you need us the most.

So let’s go back to the dial indicators, gauge blocks, and the CNC machine – they are not accurate in use without a trained operator. The same principle applies to laser shaft alignment. Most of our laser shaft alignment systems currently have 1-day free training on-site at your facility by your local solutions provider. Our laser shaft alignment tool is designed to improve your reliability and thereby reduce downtime. Avoid costly mistakes and wasted time by ensuring your operators are well trained to use these tools to their maximum potential.

by Daus Studenberg CRL

Often, welding operations such as MIG and TIG will be occurring in the presence of your laser shaft alignment system. The question often comes up: will this light energy damage the optics? The answer is no.

However, if you must weld in the presence of your laser alignment system, a greater source of damage could be from the heat, sparks, and electrical energy that is emitted from the process. We do not recommend leaving equipment attached to anything being welded due to these dangers. Welding is like having a continuous lightning strike occur and electrical voltage differences and resulting magnetic fields could cause electrical damage. Remove your equipment to protect it from such hazards.

As far as light energy goes, OSHA has standards for minimum eye-protective shade numbers ranging from “4” for gas welding to “11” for shield metal arc welding and finally up to “14” for carbon arc welding processes. NASA recommends a number “14” for directly viewing solar eclipses. All of this is for protecting the human eye, which is less resistant to damage from light than a laser detector. A laser detector is designed to continuously absorb direct laser light energy over a continuous period of time. This is far more light energy than the human eye would encounter from arcs and sunlight with proper protective gear. Warning labels caution you not to stare directly into the laser beam!

Many laser alignment systems have a special protective coating on the detector that is optimized for the specific laser wavelength of light it is intended to detect. This helps prevent interference from the bright sun from causing measurement errors. Many laser systems are used in bright sunlight, and some work better than others under such conditions. Since the welding energy would at most be of the same intensity as direct sunlight, this would most likely not cause damage. Of course, you could also put the protective caps on to be completely safe.

by Daus Studenberg CRL

The Mars Climate Orbiter was launched by NASA on Dec 11, 1998, to study the Martian climate. On its arrival at Mars on September 23, 1999, communication was lost shortly after an orbital insertion maneuver was performed.

The cause of the failure was a lower than anticipated altitude with a resulting burn-up of the orbiter. It was entirely due to human error. The error occurred because one piece of software entered the required force in pounds and a separate piece of software interpreted this as newtons. The result was a $125 million dollar lesson on the importance of consistency in units.

When performing an alignment, consistency with measurement units is the key to preventing costly errors. We recently conducted a training class for a company that worked on the metric system. Our alignment systems allow for easy conversion “on the fly” between imperial and metric units, so we simply operated everything in the metric system. We then started noticing that some students were taking much longer times on their alignments than usual. It became apparent they were misinterpreting the values of the shims, which are expressed in “thou” and thought they represented some form of a metric value. Fortunately, it was not a $125 million mistake as this can simply be a lesson to be learned in training.

When working with different units, consider all of the stakeholders involved in the project. Who will operate the tool? Who will make corrections? Who will interpret whether or not the alignment is acceptable? You will have to determine which units of measurement will be the standard for the entire project. Fortunately, if someone makes a mistake with units for corrections, they will most likely not see the alignment improving. However, if there is a mistake on units for acceptability criteria, this could be dangerous. There is a big difference between 1 mm and 1 thou! Avoid multiple conversions for the alignment process. Standardize on one set of units and remain consistent for the whole project. If there is a need to convert units during the alignment, make very sure everyone understands when this happens and why this is the case.

by Daus Studenberg CRL

In today’s world, video platform is the way to accomplish effective visual knowledge and a learning mechanism in many organizations. With the use of video, one not only is able to promote products and services but one can also strengthen a culture and demonstrate how-to scenarios easily and quickly.

LUDECA believes in communicating visually to help customers educate and train their personnel on precision skills. For this reason, we are pleased to announce the release of our new microsite www.LudecaVideos.com, which features a Shaft Alignment Know-How series plus a Know-How series for Vibration Analysis and Balancing. The video site features basic terminology, fundamental concepts, advanced measurements as well as product demonstrations. The videos are indexed by category but also searchable by keyword.

We felt there was a need to go back to basics and help educate on precision skills and related technology to improve asset reliability. Following the Uptime Elements™ holistic approach to reliability, alignment and balancing are key components of your asset condition management (ACM) program. We are happy to offer these videos to our customers for their personnel to access and for use in their training programs. We hope this content assists them and others in either improving their reliability program or in getting one started and leads to world-class reliability programs,” —Frank Seidenthal, president of LUDECA.

We encourage you to visit www.LudecaVideos.com and see for yourself the value behind each video.

by Yolanda Lopez

Guest post by Jeff Shiver, Founder of People and Processes, Inc.

As a maintenance planning and scheduling professional, I am often asked how to schedule maintenance activities when production is 24/7 or 24/6. An important question is whether the 24/7 operation is driven in part by a lack of reliability or if the organization is proactive and actually capacity constrained. In either case, the challenge is finding windows for work with the equipment stopped or shut down.

- Failure to identify smaller windows for work

- Give work to operators

- Lack of partnership between the operations and maintenance group

- Get the work done right

- Make resources available

- The right focus on preventive maintenance (PM)

- Identify failure

- Act, don’t react

- Don’t defer PM tasks

- Failure to take advantage of unplanned downtime for proactive work

- Manage the backlog

- Lack of effective coordination between the crafts

For more details, please read the full article.

by Yolanda Lopez

I recently participated in an alignment done on a boat. The alignment was between a diesel engine and V-transmission connected by a cardan shaft.

The Challenges:

- The offset between the gearbox and motor was a little over 1 inch.

- Aligning the engine to the transmission without removing the cardan shaft.

- Alignment is difficult because it has to be done while the boat is in the water, which means conditions can vary as the job is being performed.

The Solution:

- Use a ROTALIGN® ULTRA laser alignment system with compact magnetic brackets, which allow mounting the components even in very tight spaces. See Figure 1.

Using the Multi-point measurement mode allows measuring accurately even with the waves affecting the stability of the boat. This measure mode allows us to increase the number of points collected at each arbitrary measurement position. Multi-point also lets us use the “InfiniRange” feature which allows extending the measurement range of the detector during a set of readings, thus making it very easy to cope with the large misalignment across the cardan shaft.

by Carlos Bienes CRL

The need for bore alignment applies across a wide variety of industrial sectors including the marine industry, energy, oil and gas, chemical, and service companies. It is used to determine the centerline of a series of bores and setting the centerline relative to any fixed reference, or aligning the bores to a rotating shaft, and/or determining the out-of-roundness of bores. One common example is the alignment of large gas and steam turbines.

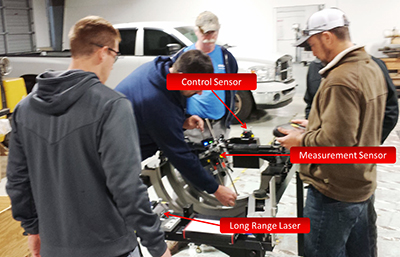

However, one problem often encountered with performing laser alignment on large turbines is that over long distances and long measurement periods, laser stability is subject to be impacted by variations in air density, temperature, or light, the cumulative effect of which is often referred to as “laser drift”. To ensure measurement accuracy, an additional fixed sensor, called a control sensor, can be installed to monitor the amount of laser drift at the far end of the turbine. When used with the CENTRALIGN® ULTRA EXPERT application, the laser drift data from the control sensor is automatically applied to the bore measurements taken by the measurement sensor to provide true bore center measurements under any conditions over longer periods of time.

by Tim Rogers CRL

- Right safety procedures before you align.

- Right machines to align.

- Right alignment procedure.

- Right alignment tool.

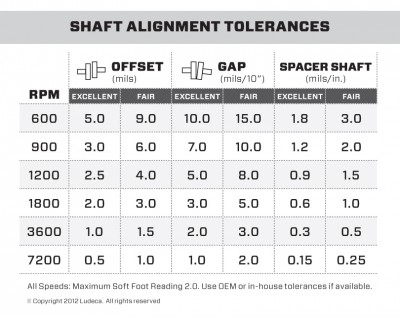

- Right alignment tolerances.

- Right alignment targets.

- Right soft analysis and correction.

- Right shims.

- Right moves.

- Right bolt tightening sequence.

- Right bolt torquing.

- Right alignment report.

by Ana Maria Delgado, CRL

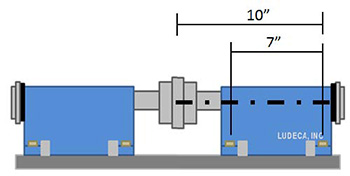

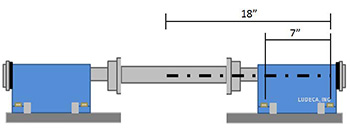

When using short-flex coupling tolerances, the centerline of rotation of each machine is aligned at the coupling center, which is the center between the flex planes, or the average center of power of transmission points. Using simple geometry, it’s easy to see why short-flex coupling tolerances are too tight when using spacer couplings. In this example, the only variable is the axial length of the coupling. A small short-flex coupling is compared to a long spacer coupling, but the machine used and feet corrections remain the same. This makes it easy to see how the length of the coupling affects the movement of the centerline of rotation at the coupling center.

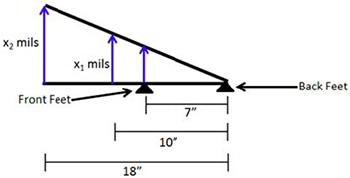

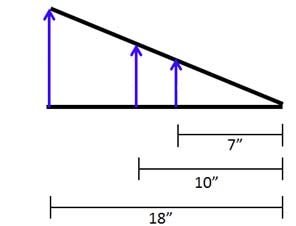

The dimensions required for this example are shown in the figures below. In Figure 1, the front and back feet of the machine are 7″ apart. The distance from the back feet to the centerline of rotation at the coupling center of the short flex coupling is 10″. In Figure 2, the latter dimension, which is 18″, represents the distance from the back feet to the center of a 16″ spacer coupling. Note that this coupling center extends 8″ (half of the spacer coupling length) past the first flex plane or first point of power transmission.

In the next step, a 2-mil shim is added to the front feet of the right machine, and the back feet are left untouched. This correction is arbitrary and can be represented using three equivalent triangles as shown below.

The total movement of the centerline of rotation at the center of each coupling type is represented by x1 for the short coupling (Figure 1) and x2 for the spacer coupling (Figure 2). These values can be found by setting the ratios of each triangle’s legs equal to each other.

(1 “mil” )/(7 “inches” )=(x_1 “mils” )/(10 “inches” )=(x_2 “mils” )/(18 “inches” )

The figure below shows the total movements at the coupling centers.

After adding 2 mils to the front feet of the machine, the centerline of rotation moved 2.9 mils at the short-flex coupling center and 5.1 mils at the middle of the spacer coupling. That’s a 76% larger movement at the spacer coupling center! This goes to show that the further away the coupling center is from the moveable machine’s feet, the more sensitive the movement will be. It may take all day to align the machine with a spacer coupling to short-coupling tolerances because a small movement at the feet turns into a large movement at the coupling center. The machine may even be aligned within an appropriate spacer shaft tolerance, but the tool will still show that there is misalignment if short-flex coupling tolerances are selected. As a rule of thumb, if the coupling length is smaller than 4″ between flex planes, use short-flex tolerances. If this distance is greater than 4″, use spacer shaft tolerances and make your life easier.

by Silvio Attanasio CRL

When there is a lack of repeatability, or unexpected results are obtained during laser shaft alignment, a simple functionality test can be performed on the alignment tool’s heads to determine if they’re working properly. This can be achieved on a laser-and-sensor system, such as the ROTALIGN® ULTRA IS, or a transducer-and-prism system, such as the SHAFTALIGN® OS3. If the system passes the functionality test, it is most likely working properly. However, this test does not replace an official calibration check.

Perform the following procedure if there is doubt that your laser alignment tool’s heads are not working properly:

- Mount the heads on a piece of stiff pipe about six to ten inches apart. Do not use pipes that are smaller than two inches in diameter. Also, do not use solid shafting or bar-stock. The pipe does not have to be perfectly straight, but its surfaces should be smooth enough for the brackets to be mounted on.

- Enter the dimensions. Use the halfway point between the heads as the coupling center. Set the coupling diameter to ten inches. The remaining dimensions are irrelevant.

- It is ideal to mount the pipe on V-blocks, but this step can be performed with your hands as well: Center the laser beam on the dust cap. Remove the dust cap and take a set of readings while rotating the pipe 360 degrees. The coupling results should be zero or very close to it.

- Repeat this procedure at least four more times. Position the laser at different locations on the detector each time.

It’s as simple as that. If the coupling results are not consistently close to zero, the heads will likely need to be calibrated. We recommend that you have your heads calibrated every two years for optimal performance.

by Silvio Attanasio CRL

LUDECA Inc. has been recognized by the Society for Maintenance and Reliability Professionals (SMRP) as an approved provider of continuing education and training aligned with key subject areas related to reliability and physical asset management.” said Ron Leonard, SMRP CMRP Chair of APEP Committee

As an SMRP Approved Provider, LUDECA is recognized for its best-in-class continuing education training programs for precision shaft alignment of rotating equipment and precision balancing as part of reliability and physical asset management. LUDECA is a Tier 2 Approved Provider with courses that are taught on-site, regionally, or at their own state-of-the-art training center in Doral, FL.

As an SMRP Approved Provider, LUDECA is recognized for its best-in-class continuing education training programs for precision shaft alignment of rotating equipment and precision balancing as part of reliability and physical asset management. LUDECA is a Tier 2 Approved Provider with courses that are taught on-site, regionally, or at their own state-of-the-art training center in Doral, FL.

The following are currently approved courses that map to SMRP’s Body of Knowledge Pillar #3 – Equipment Reliability:

- 3-day Advanced Shaft Alignment Course (21 hours)

- 4-day Comprehensive Shaft Alignment Course (28 hours)

- 3-day Balancing Course (21 hours)

We are thrilled to be part of this select group of training companies.” says Ana Maria Delgado, CRL, Marketing Manager for LUDECA. “Our company has always made it a priority to deliver quality hands-on training with alignment and balancing best practices to improve asset reliability. Our new SMRP Approved Provider status provides us with the opportunity to enhance our commitment to our customers and to the success of their reliability programs.”

About LUDECA

LUDECA is a leading provider of Preventive, Predictive, and Corrective Maintenance Solutions, including machinery laser alignment, vibration analysis, and balancing equipment as well as software, rentals, services, and training. For more details, visit www.ludeca.com

About SMRP

The Society for Maintenance & Reliability Professionals (SMRP) is an international, nonprofit society dedicated to promoting excellence in maintenance, reliability, and physical asset management. Its 4,000 members specialize in achieving improved efficiency and profitability across many industries by applying best practices and proactively managing operations, equipment, and people. SMRP provides ANSI-accredited professional certification to validate the critical knowledge and skills of the top practitioners in the profession. For more information, visit www.smrp.org.

by Ana Maria Delgado, CRL