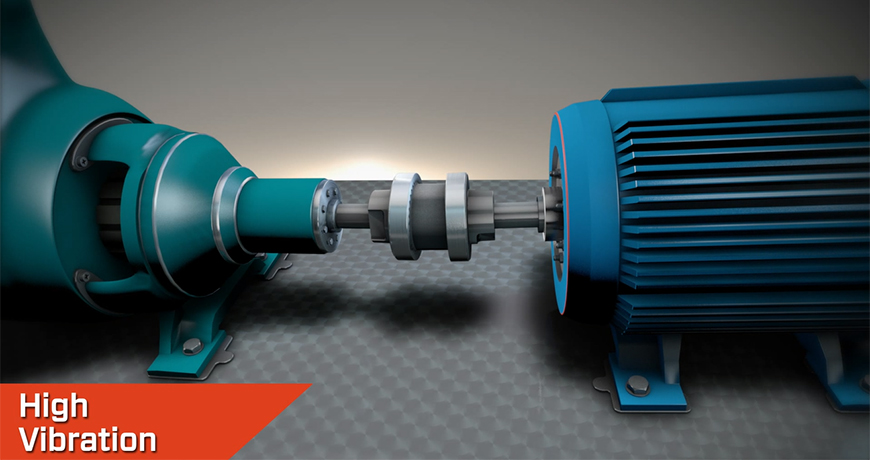

Vibration is everywhere! Vibration is a “back and forth” movement of a structure or component. Vibration can also be referred to as a “cyclical” movement. It can be inherent in a piece of equipment or can be induced by another form of energy. The real question is whether the vibration is detrimental to the equipment and its internal components.

Vibration is typically monitored through some form of analyzer, either online or offline such as the VIBWORKS analyzer.

What causes vibration? Here are just a few causes, but there are so more which can lead to elevated vibration levels. More importantly, if caught early enough, they can be corrected and thereby maximize the life of our equipment:

- Installation of the machines

- An improperly mounted bearing can cause severe vibration. This can lead to damage of the bearing as well as other components within the machine.

- Operation of the machine

- Pushing our machine beyond its recommended maximum output. Our machines respond by vibrating more than the recommended allowable limits and will eventually fail.

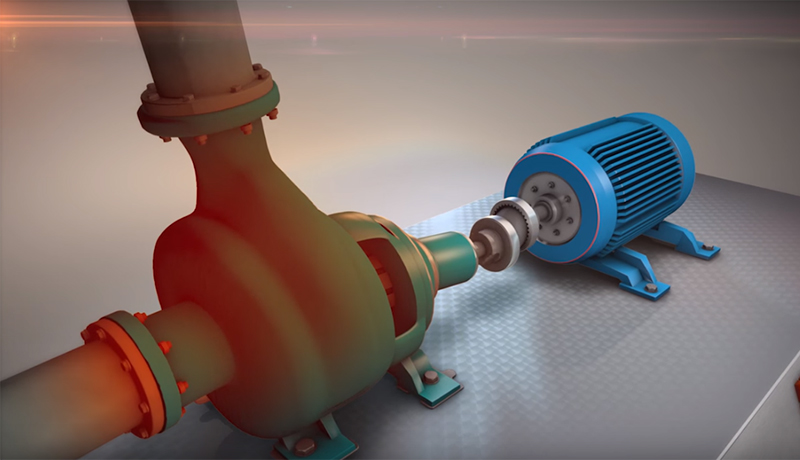

Watch our video ‘What’s Misalignment’ to learn more about the causes and effects of having misalignment in your rotating equipment

Some common machine problems that generate mechanical vibration:

- Misalignment

- Misalignment is one of the most common issues that leads to high vibration and eventually failure of the machine. It can be easily detected and corrected. Take the time to laser align machines properly to the recommended tolerance.

- Unbalance

- Unbalance is another easily missed problem that causes severe damage to our equipment. It can also lead to cracks of the housing itself. If not detected and corrected soon enough it can lead to dangerous catastrophic failure. Unbalance can be easily detected and corrected extending the life of the equipment.

We never have enough time to do things right the first time but always find time to do them again.”

These few issues can be easily detected with properly set-up software. Often, the setup is incorrect and inaccurate. Invalid data is captured in the FFT. Please consult an expert to make certain you are utilizing your condition monitoring software to its fullest potential. Remember… If it’s Critical and Rotates it should be Aligned, Balanced, and Monitored.

by Ana Maria Delgado, CRL

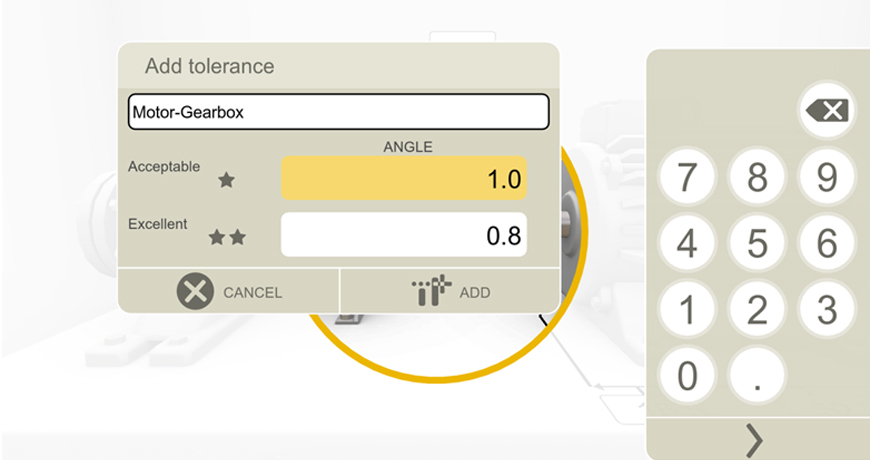

A couple of months ago, we were hired to perform an alignment on a motor/gearbox setup with a 9-foot spacer coupling in between. The obstacle this time around was that the spacer coupling was going through a steel support beam. The coupling is round but the hole in the beam was square, just big enough for the coupling to go through. With a circle going through a square, only the corners of the hole were open. This meant that line-of-sight between the two lasers was limited. Because of the obstruction there was no way to obtain data with a continuous reading. Using our dual-laser XT660 system, we decided to take readings in each available corner. We could have taken one point at each 45 degree position. However, taking more points is always beneficial. We decided to take three points (close together) in each of the corners. With two rotations, we obtained excellent repeatability. Once we had repeatable readings, we moved the machine according to the calculated alignment results and aligned it to our customer’s customized tolerances.

Many times we are faced with awkward alignment situations. It is helpful to have an alignment tool that is very easy to use, yet versatile to adapt to these situations. It helped that the Easy-Laser® XT660 allowed us to change measurement modes (in this case to Multipoint mode). It also helped that the tool allowed us to adjust our tolerances to the customer’s particular needs. The customer did not want to use the built-in Easy-Laser tolerances, nor the ANSI standard tolerances that are included in the system. Instead, they were looking to align the machines to within 0.1 thou/inch (or 1.0 thou/10 inches) of angular misalignment at each flex plane. So we created a custom tolerance instantaneously within the tool for this job. The customer was satisfied with the alignment and the report generated with their tolerances.

Learn more about Precision Alignment from Adam Stredel at our Rethink Maintenance Training Roadshows

by Ana Maria Delgado, CRL

As Published by Maintworld March 2018 issue

When it comes to shaft alignment, experts from industrial service provider Bilfinger have relied on the co-operation with Swedish company Easy-Laser for nearly two decades. Now, the company is introducing a new generation of devices, which will greatly simplify the alignment process for clients and employees, especially in potentially explosive environments.

Maintenance Personnel at Bilfinger Maintenance in Höchst have been using laser-based measurement and alignment systems from Easy-Laser since 2001.

In addition to cost factors, the main deciding factor in our collaboration with Easy-Laser was their user interface, which is easy to understand and, there-fore, very user-friendly, explained Karl-Heinz Bank, head of Machine Technology and Service Technicians at Bilfinger Maintenance in Höchst.

In spring this year, the good working relationship strengthened further. After Easy-Laser had officially launched their XT550 EX shaft alignment system at the Hannover trade show, the innovative measurement system was delivered to Bilfinger, who was the first customer.

Without doubt, the old systems that had been in use for a long time were still reliable, as confirmed by Mr. Jurgen Rabe, Head of Pump and Engine Technology at Bilfinger in Höchst. However, the industry had been waiting with great anticipation for a new shaft alignment system.

Read entire article: “Bilfinger Maintenance Ensures Innovative Shaft Alignment“

by Ana Maria Delgado, CRL

MYTH: “You should always do your shimming first and then make your horizontal moves.”

TRUTH: This is generally true for the final alignment after soft foot has been corrected, but is not universally true for all alignments. In fact, for the initial rough alignment you should correct the plane with the largest misalignment first, even if this means making a horizontal move first. Reason: If you have gross misalignment, you could be binding the coupling, deflecting the shafts and imposing undue load on the bearings. By relieving strain from excess misalignment, a truer picture of the alignment condition emerges, and you eliminate an important outside force that creates machine frame distortion (soft foot). Therefore, the correct sequence of events in any alignment job is:

- Safety: Lockout & tag out plus clean up

- Rough Align

- Find, diagnose and eliminate Soft Foot.

- Final Alignment: shimming first, then moves.

Download 5-Step Shaft Alignment Procedure

Check out our SS Precut Shims.

by Yolanda Lopez

December 2018 – EFFICIENT PLANT

The recently released Alignment Standard (ANSI/ASA S2.75-2017) from the American National Standards Institute, Washington (ansi.org) took nearly three years to develop. A committee of alignment experts discussed every aspect from safety procedures to the mathematics involved in defining the new standard. Alan Luedeking, CMRP, CRL, of Ludeca Inc., Miami (ludeca.com) a member of that committee, has been involved in the development of alignment standards for significantly longer than three years.

Luedeking remembers the “old days” well. Back then, personnel simply aligned components to the best of their abilities with straightedges or dial indicators. “Those alignments,” he said, “usually weren’t that good, due to sag, span limitations, obstructions to rotation, or whatever. But you did the best you could, and that was good enough because it was all you could do.”

In 1982, Ludeca introduced the world’s first computerized dial indicator alignment system (from the now-defunct Industrial Maintenance Systems Inc.), followed in 1984 by the world’s first laser-alignment system. With the improved measurement resolution and accuracy afforded by the laser sensor, a more precise definition of what constituted a good alignment became necessary. So, according to Luedeking, after poring through the sparse alignment literature that existed, Ludeca developed tolerance tables for short and spacer couplings, which, for lack of anything better, end users readily accepted. “Over time,” he noted, “these tolerance values came to be accepted as the U.S. industry standard and were adopted as the official tolerance standard by various corporate and government entities, including NASA and the U.S. Navy.”

So what are alignment tolerances, and why are they important? As Luedeking described them, “Tolerances exist because absolute perfection does not. No matter how hard you try and how long you work, you will never get a shaft alignment absolutely perfect.” He offered the following detailed discussion as to why, along with some expert advice on the meaning of the new standard and how it can help you improve your operations. Read the entire article “Alignment Tolerances Carved in Stone”

Check out the Easy-Laser XT Series, the only laser alignment platform on the market today with the new ANSI alignment tolerances built-in giving the user the freedom to choose between traditional tolerances, the new ANSI standards, or custom tolerances of the user’s own choosing.

by Ana Maria Delgado, CRL

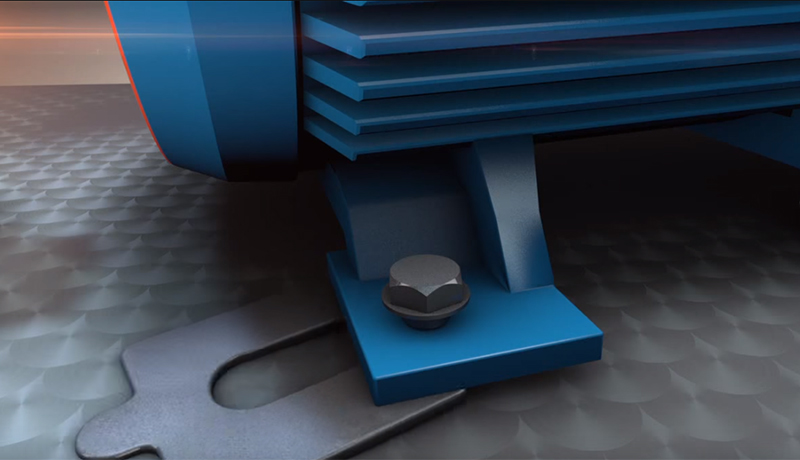

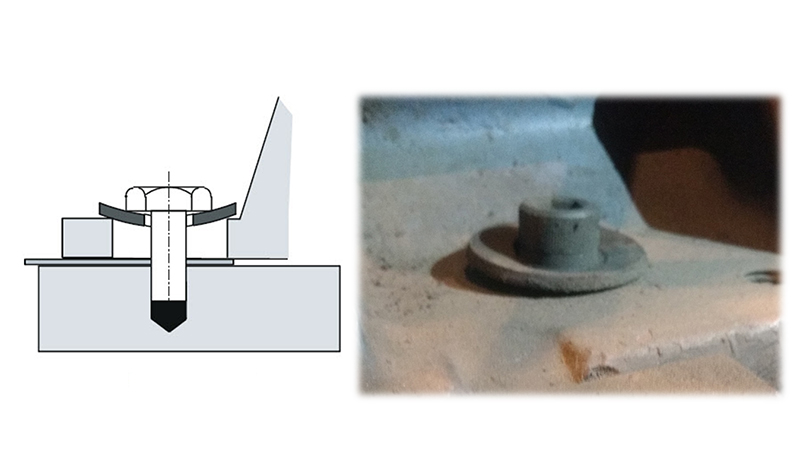

Often, maintenance departments invest in good quality Bolts and Nuts (Grade 8), but neglect to do the same with flat washers. The importance of a good washer cannot be overstated. If you use a typically thin Grade 2 (or worse) flat washer under the bolt head of the hold-down bolts of your machine, this washer will easily be distorted or warped into the hole in the foot upon tightening the anchor bolt. This is particularly true if the difference in shank diameter of the bolt and hole diameter in the foot is significant. This will often be the case when the hole in the foot has been enlarged to overcome a bolt-bound problem. The result of having “dished” washers is that when the anchor bolts are tightened after completing the alignment, the washers will try to center themselves in the hole in the foot and in doing so will pull your machine out of alignment again. This effect is virtually impossible to overcome, resulting in a badly misaligned machine after you just did a good alignment!

Often, maintenance departments invest in good quality Bolts and Nuts (Grade 8), but neglect to do the same with flat washers. The importance of a good washer cannot be overstated. If you use a typically thin Grade 2 (or worse) flat washer under the bolt head of the hold-down bolts of your machine, this washer will easily be distorted or warped into the hole in the foot upon tightening the anchor bolt. This is particularly true if the difference in shank diameter of the bolt and hole diameter in the foot is significant. This will often be the case when the hole in the foot has been enlarged to overcome a bolt-bound problem. The result of having “dished” washers is that when the anchor bolts are tightened after completing the alignment, the washers will try to center themselves in the hole in the foot and in doing so will pull your machine out of alignment again. This effect is virtually impossible to overcome, resulting in a badly misaligned machine after you just did a good alignment!

Solution: Always discard warped washers and use high quality thick flat washers that will not distort or warp into the hole. This will allow the washers to do their job of supporting the bolt head’s load on the surface of the foot.

Take a look at our Shaft Alignment Tools!

by Yolanda Lopez

MYTH: “All Soft Foot can be corrected by proper shimming.”

TRUTH: Soft Foot is Machine Frame Distortion. This can sometimes be caused by problems not easily fixable by shimming, like pipe strain, which can only be properly corrected by adjusting the piping and interface with the machine. A good laser system with positional change monitoring capability (such as EASY-LASER XT770 with Easy-Trend) is the best way to detect and measure the effects of pipe strain.

Watch and learn more about Soft Foot!

by Yolanda Lopez

MYTH: “Pipe Stress makes the alignment difficult.”

TRUTH: Pipe stress does not have any significant influence on the alignment unless you make corrections on the machine with the piping attached. In most alignment, the corrections to eliminate misalignment are performed on one machine only, typically the one that is easier to move. In a pump-motor set, the corrections are done on the motor. If there is sufficient room to shim and move, excellent alignment can be achieved regardless of how much pipe stress there is on the pump. Of course, pipe stress is undesirable and should be eliminated prior to the alignment.

Watch and learn more about Pipe Stress

by Yolanda Lopez

We often hear “Coupling alignment tolerances provided by the coupling manufacturer are good enough for shaft alignment.” or “There’s no need to align your machines tighter than the tolerances allowed by your flexible coupling.”

This is wrong because good quality flexible couplings may be built to withstand much more misalignment than what is good for your connected machines, in terms of the vibration and other forces created. Bearings and seals may wear out and fail faster than a highly misalignment-tolerant coupling. The reason for this “extra misalignment capacity” in flex couplings is that they may need to withstand significant positional changes resulting from thermal growth or dynamic load shifts. This lets you deliberately misalign machines to “cold alignment” targets.

Take a look at our Shaft Alignment Tools

by Yolanda Lopez

We just returned from performing a stern tube bearing carrier alignment on a large container vessel currently in construction at a leading US shipyard. The one-meter diameter bearing carriers needed to be set to specific tolerances with respect to an established datum line along the longitudinal axis of the ship. Historically, this was accomplished using optics, piano wire and depth gauges. The procedure was time consuming and considering the sizes of some of the vessels being fabricated, performing an alignment was tedious and time consuming work. Sunlight on the hull can cause considerable movement; therefore a faster alignment process would be desirable. Therefore, we were asked to bring in the Easy-Laser E950-B bore alignment system. The quick setup and operation of this wireless laser alignment system made taking bore straightness readings a breeze, saving valuable time on a warm sunny morning in dry dock. The client was pleased with the speed with which the job was performed and the ease of understanding results—a testament to the straightforward design of the E-Series software.

by Yolanda Lopez

Reposted from People and Processes, written by Jeff Shiver CMRP, CPMM, CRL

Do you find yourself wondering why your employees haven’t taken the initiative and approached you for additional training? Well, they must not want the extra training, right? Wrong! Sometimes, employees do want training, but they just don’t ask. Here’s why:

1. THEY HAVE FEAR OF REJECTION

People don’t like to be told no! The majority of employees don’t understand the organization’s vision, goals, brand promise, or key initiatives.

2. THEY FEEL UNSUPPORTED

Employees get worn out from a culture of mediocrity being tolerated, commitments not honored, and requests being ignored.

3. THEY DON’T KNOW HOW TO ASK

Operators, Mechanics, Planners, and even Managers may not understand how to equate the returns of training.

4. THEY DON’T KNOW WHEN TO ASK

Many employees don’t know when there is flexibility within the budget.

5. THEY ARE AFRAID OF BEING NEEDY

If no one else is asking for training, then why should they expect to be treated differently?

6. THEY FEEL AWKWARD OR UNCOMFORTABLE

There must be a commitment for development and the line of communication should be open.

7. THEY DON’T FEEL CHALLENGED

They may be topped out and let with nowhere to go from a promotional perspective.

8. THEY DON’T KNOW WHAT THEY DON’T KNOW

When people have never been exposed to anything else, they don’t know what else is possible.

Keep these things in mind the next time you offer training, or feel that your employees should ask you if they want it. A better approach may be discussing this with your employees individually.

Check out LUDECA training offering for alignment, geometric measurements, vibration analysis, balancing and ultrasound.

by Ana Maria Delgado, CRL

Guest Post by Ricky Smith, CRL, CMRP, CMRT

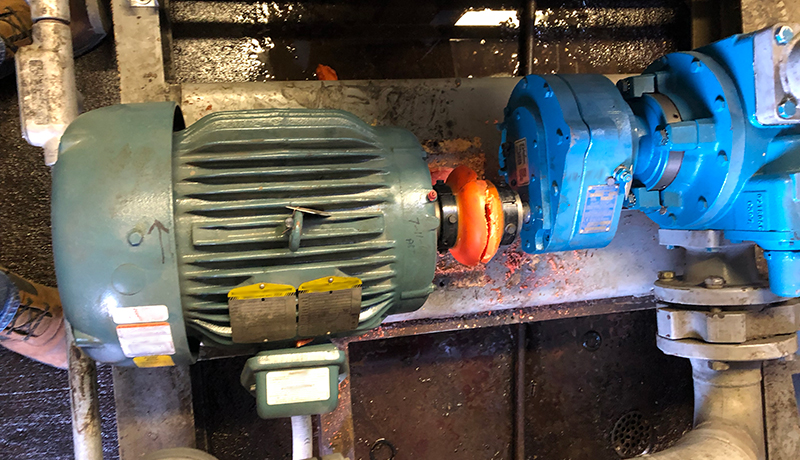

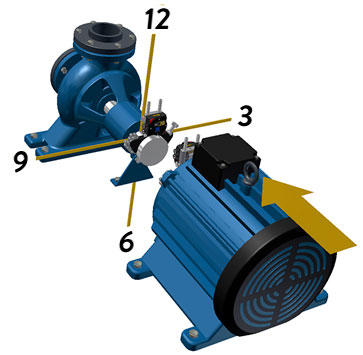

Pipe stress is caused by misalignment of the mating surfaces of two pipe flanges creating abnormal internal stress of pump bearings, seals, motor bearings, and couplings, and can possibly change the displacement of a pump.

General Rules which must be followed by maintenance personnel and contractors: (if you truly want to stop a long term pump problem)

- Pipe flanges attached to pumps must be aligned where the gap does not exceed the thickness of two gaskets or the tolerance established by your company’s engineering standards.

- Pipe flange bolts must drop in without assistance.

- Cable pullers, come-a-longs, or long bars should not be used when aligning a flange that is connected to a pump.

- Validate the elimination of pipe stress by following the guidelines listed below.

Failure Modes experienced from Pipe Stress on Bearings:

- Wear caused by seals leaking

- Wear caused by static vibration

- Indentations caused by overloading while static

- Corrosion caused by inadequate lubrication caused by abnormal loading (seal leaking)

- Flaking caused by misalignment and excessive loading

WARNING: Ensure your contractors follow the same process to eliminate pipe stress. Pipe stress elimination should be validated during the commissioning of a new pump.

Follow this process if you want to inspect your pumps that may have pipe stress:

- Align the two shafts between your pump and driver (typically an electric motor) to the tolerance recommended by the equipment vendor or your company’s engineering standards.

- Validate misalignment to insure motor and pump shafts are aligned to specification.

- Disconnect the outlet flange on the pump.

- Revalidate laser alignment of shafts.

- If alignment has moved then you have pipe stress. Do the same for the inlet flange.

- Make corrections as stated in the following procedures to eliminate pipe stress.

Elimination of Pipe Stress – “The Ricky Smith Method for Pipe Stress” as learned from Dan Turner (his maintenance and engineering manager at Exxon during his career in the 1970s)

- Bolt flanges to pump and insert blind flange gasket along with two regular flanges between pump and mating flanges (cover the hole between the welding area and inside the pump).

- Attached welding ground to flange. (do not attach ground lead to pump; welding group must always be attached to flange) WARNING: Failure to accomplish this one task properly will cause bearing failure by “electric arcing” which is a failure mode of bearings.

- Tack weld flange into place reverse welding each tack.

- Allow cooling for 10 minutes.

- Reverse stitch weld on opposite sides on the flange is similarly used for cast iron welding.

- After initial reverse stitch weld then weld normally using electrode recommended by the American Welding Society (typically E-6010 5P or GTAW)

- After root pass; weld in any direction you wish.

- Allow to cool and then disconnect flange, replace gaskets and;

Validate bolts will drop into holes without a pry bar.

Validate gap between flanges is no more than two gaskets thick.

To learn more about the effects of running equipment with pipe stress, watch the LUDECA Shaft Alignment Know-How Pipe Stress tutorial video.

by Yolanda Lopez

Guest Post by Bob Dunn from I&E Central, Inc.

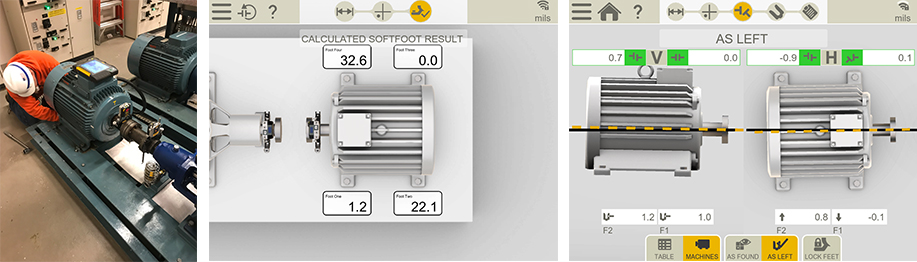

I had the opportunity to use the Easy-Laser XT440 to assist a customer in aligning a machine that had perpetually given them problems, with bearings always running hot. They had recently aligned the machine with dial indicators, but when we checked, it was off by .007, and this was on a 3600 RPM motor. We removed their old shims and did a soft foot check indicating .032 under one of the feet. Further inspection showed an angular gap under one foot. It turns out that when new, someone had ground down the feet on the motor to better align to the pump – obviously not a precision job. We step-shimmed to fill the angular gap, then aligned the machine in a single move. Several of the techniques we used were unfamiliar to these mechanics.

Takeaways:

- Do your pre-alignment homework to detect and correct foundation issues.

- Be sure mechanics are really trained in alignment – not just how to push the buttons. By the way, Ludeca Inc. and I&E Central provide excellent training.

- The Easy-Laser XT-Series is a fast, accurate, and incredibly easy-to-use tool for coupling alignment and more. If you use something else, you should see what you are missing!

by Ana Maria Delgado, CRL

As Published by Solutions Magazine March/April 2018 issue

by Ana Maria Delgado, CRL and Shon Isenhour, CMRP CAMA CCMP, Founding Partner at Eruditio LLC

During the many root cause analysis (RCA) investigations we facilitate and coach, we notice some themes that continue to manifest themselves in the findings. Often, they are grouped under the heading of precision maintenance or lack thereof. Let’s take a look at some of them and determine if they are also killing your reliability.

The six killers are grouped into three areas: Lubrication, Misalignment, and Undiagnosed Wear.

Click here to read the full article.

by Ana Maria Delgado, CRL

Guest post by John Lambert at Benchmark PDM

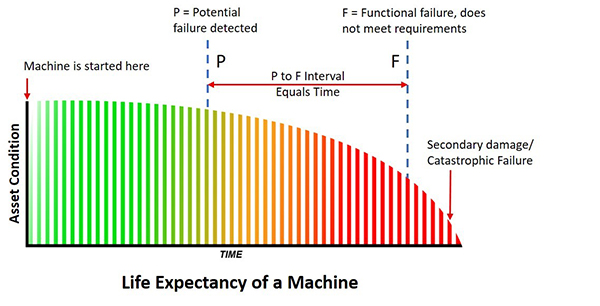

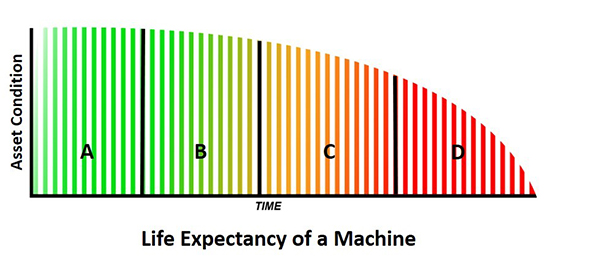

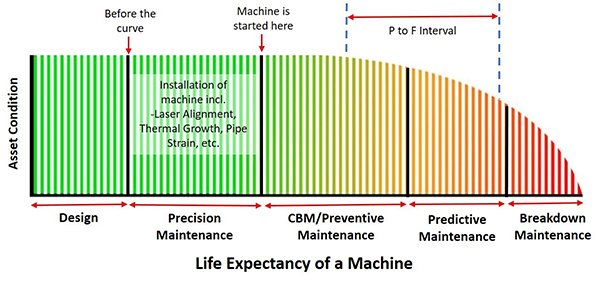

Recently I have been seeing the P to F interval curve popping up a lot on my LinkedIn feed and in articles that I have read. It was a concept that I was first introduced to when I was implementing Reliability Centered Maintenance into the Engineering and Maintenance department at the plant where I worked at the time. It was a great idea, that if done correctly is a maintenance benefit. Why, because it’s cost savings and cost avoidance. Let me explain this.

The P to F curve was used as a learning tool for Condition Based Maintenance. The curve is the life expectancy of a machine, an asset. The P is the point when a change in the condition of the machine is detected. The F is when it reaches functional failure. This means that it is not doing the job it was designed to do. For example, if it were a seal that is designed to keep fluids in and contamination out and is now leaking, it’s in a state of functional failure. Will this put the machine down? Probably not, but it depends on the importance of the seal and the application. This is an important point because the P (potential failure) is a fixed point when you detect the change in condition but the F (failure) is a moving point. Not all warnings of failure put the machine down very often you have options and time. Consider this: If I have a bucket that has a hole in it, it is in a functional failure state. But can I still use it to bail out my sinking boat? You bet I can!

Failure comes at us in many ways and obviously, we have many ways to combat it. If you detect the potential failure early enough (and it can be months and months before actual failure) it means that you can avoid the breakdown. You can schedule an outage to do a repair. It’s not a breakdown, the machine hasn’t stopped, it’s no downtime. This is cost avoidance and the plant can save on the interrupted loss of production because of downtime costs.

There are a lot of examples of cost avoidance and also of cost savings. For instance, at the plant I worked at we used ultrasound to monitor bearings. We detected a very early warning in the sound level and were able to grease the bearing and the sound level dropped. We saved the bearing of any damage, and we saved a potential breakdown so this is cost savings. Even if there is some bearing damage, the fact that we are aware of and monitor the situation lets us avoid any secondary damage.

It’s one price to replace a seal and it’s more if you have to replace a bearing in a gearbox. However, it can be very expensive to have to replace a shaft because the bearing has sized onto it and ruined it. Secondary, ancillary damage can mount up very quickly if you don’t heed the warning you are given with the P of potential failure. This warning of potential failure gives you time before any breakdown. The earlier the detection, the more time. Time to plan, and view your options. And what people tend not to do is failure analysis while the machine is still in service. A failure analysis gives you a great start on seeking out the root cause but starts right away, not when the machine is down.

Condition monitoring or as it’s often called Condition-based maintenance (CBM) does work. However, for me, there is a downside to this and I will explain why shortly. CBM is based on measurement, which is good because we all know to control a process we must measure.

Consultants (and I’m guilty) like to put labels on things and you may see:

1. Design, Capability, Precision Maintenance

2. CBM, Predictive Maintenance

3. Preventive Maintenance

4. Run to Failure, Breakdown Maintenance

For me, the P to F interval curve starts when the machine starts. That means Design and Precision Maintenance is not in the curve and this happens before startup. A small point but it takes away from the interval meaning.

We use predictive maintenance technologies in CBM. Vibration, Ultrasonic, Infrared, Oil Analysis, NDT (i.e. pipe wall thickness), and Operational Performance. They are all very good technologies, yet it is a combination of cross-technologies that works best. As an example, vibration may give you the most information yet ultrasound may give you the earliest warning on a high-speed bearing. And then there is oil analysis which may be best for a low-speed gearbox. It all depends on the application you have which dictates what’s best for you. A lot of time and effort was placed on having the best CBM program and buying the right technology.

This, I believe, lead to the maintenance departments putting the focus on Condition-based maintenance! This I think is wrong because we still have failure. This means that CBM is no better than Predictive Maintenance. This doesn’t mean that I don’t recommend CBM, I do. To me, it’s a must-have but it does not improve the maintenance process because you still have machine failure. Machine failures fall into three categories Premature failure, Random failure, and Age-related failure. We want the latter of these. We know from studies that say that 11% of machine assets fail because of age-related issues. They grow old and wear out. This means that 89% fail because of some other fault. This is a good thing because it gives us an opportunity to do something about them.

These numbers come from a very famous study by Nowlan and Heap (Google it!) that was commissioned by the US Defense Department. It doesn’t mean these numbers are an exact reflection of every industry but the study but it has stood the test of time and I believe it has led to the development of Reliability Centered Maintenance. But let’s say it’s wrong and let us double the amount they say is age-related (full machine life expectancy). That would make it 22% and 78% would be the number of random failures. Even if we quadruple, it’s only 44% meaning random is at 56% and we are still on the wrong side of the equation. The maintenance goal has to be to get the full life expectancy for all their machine assets.

In order to get the full life expectancy for a machine unit, I think you have to be assured of two things. One is the design of the unit which includes all related parts (not just the pump but the piping as well). The other is the installation.

If you’re like me, and you believe that Condition Based Maintenance starts when the machine starts then you understand that there is a section of the machine’s life that happens before. You could make an argument that it starts when you buy it because, as we all know, how we store it can have an effect. However, what is important at this stage is the design and installation of the machine. In most cases, we do not design the pump, gearbox, or compressor but we do size them so that they meet the required output (hopefully). We do quite often design the piping configuration or the bases for example. All of which is very important but the reality is that maintenance departments maintain already-in-place machine assets. So, although a new installation, requiring design work is not often done, installation is. Remove and Refit is done constantly. And the installation is something that you can control. In fact, it’s the installation that has the largest influence on the machines’ life. The goal is to create a stress-free environment for the machine to run. No pipe strain, no distorted bases, no thermal expansion, no misalignment, etc.

Precision Maintenance was a term I first heard thirty years ago. It’s part of our M.A.A.D. training program (Measure, Analyse, Action, and Documentation). It’s simple, it means working to a standard. Maintenance departments can set their own standards. However, all must agree on it and adhere to it. This is the only way to control the installation process. This is the way to stop random failure and get the full life expectancy for your machine assets. The issue is that we do not have a general machinery installation standard to work to. Yes, we can use information from other specific industry sources such as the American Petroleum Institute (API) or the information from the OEM (both of these are guidelines) however nothing for the general industry as a whole. Well, this is about to change. The American National Standard Institute (ANSI) has just approved a new standard that is about to be published. I know this because I worked on it and will be writing about it shortly.

If you look at the life cycle of a machine, we need to know and manage the failure as best we can. If we only focus or mainly focus on the failure, we will not improve the reliability of the machine. We cannot control the failure. What we can control is the installation and done correctly this will improve the process giving the optimum life for the machine.

I sell laser alignment systems as well as vibration instruments. If a customer were to buy a vibration monitoring tool before they bought a laser system. I would think their focus is on the effect of the issue, not the cause. What do you think?

by Ana Maria Delgado, CRL

In the 35+ years of experience that LUDECA has in shaft alignment, we have been asked this question many times. How long does it take to do an alignment? People in charge of scheduling have a tough task when allotting time for technicians to do an alignment with precision. In many cases, they may just take a guess, based on the average time it has taken in the past. The answer is not so simple. During a one-day seminar, I had to perform an alignment on a motor to a pump to show the proper steps when aligning a machine. When the time came to start the alignment, all the safety procedures had been taken care of, and the machine had been rough aligned. The soft foot values were within tolerances. So I was able to align the machine in under 45 minutes, within the tolerances specified for 1200 RPM.

On another occasion, I was hired to help align a generator to a turbine. Quite a few things went right as well. The safety procedures had been taken care of by the time I got there. The coupling guard and coupling element had been removed. The machine had also been rough aligned. The special-order shims for the generator feet were available on-site. Even with all these things going my way, this alignment took a day and a half to finish. There are things that come up during an alignment that cannot be planned for. One of them is a soft foot condition. Not checking for soft foot can greatly increase the time it takes to align a machine, mainly because the response to corrections stipulated by your alignment tool will not be accurate. Therefore, knowing the soft foot condition and minimizing it, is key. However, that in itself can take up a long time, depending on the condition of the baseplate, the condition of the anchor bolts, washer, pipe stress, etc.

In both cases, they were a single coupling alignment. Aligning a large generator is obviously more difficult than a 200HP motor. In the first case, I was able to turn the motor with a strap wrench by myself. In the case of the generator, it needed to be uncoupled because the two machines could not be turned together. In most cases, a larger machine takes longer to align because breaking the bolts loose, alone, could take 20 to 30 minutes. Furthermore, there can be a large difference in the amount of time it takes to finish an alignment, between two identical machine sets. The information obtained here can help reduce the alignment time.

I recommend downloading our 5-Step Shaft Alignment Procedure and/or requesting our Shaft Alignment Fundamentals Wallchart for your alignment team. The point is that there is no fixed amount of time required for an alignment of a machine. If a scheduler should err, it should always be on the conservative side.

by Adam Stredel CRL

Reposted from Easy-Laser®

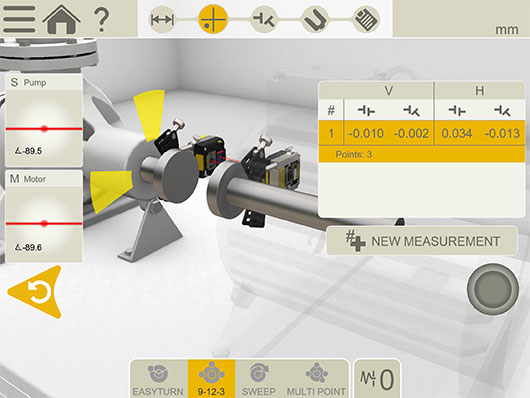

The latest addition to Generation XT, Easy-Laser® XT660, gives you access to four different measurement methods for shaft alignment. Each with its own advantages. Read more to find out how to use them best!

The four measurement methods are 9-12-3, EasyTurn™, Multipoint, and Continuous sweep. Here we describe them individually so that you know when best to use them.

Method 1: 9-12-3

The clock method, or 9-12-3 as it is also known, is the origin of all shaft alignment. Anyone who knows how to use analog dial indicators will recognize this method. A dial gauge is mounted on each shaft, and the measurement values are taken at three different points, corresponding to the 9-12-3 positions on a clock, or the angles 0-90-180 of a circle. It is based on geometry (and trigonometry), more specifically circle mathematics. The mathematical assumption is that if we can measure the semicircle, we can then work out what the whole circle will look like, and consequently determine the center of the circle (rotational center) for both shafts. These centers can then be compared to each other and we can thus work out how well-aligned the machines are to each other. And with a laser-based measurement system, also obtain direct feedback from the adjustment of the machine in real-time.

When should this method be used? One answer is that this method can always be used when you are able to rotate the shafts freely, and there are no other physical obstructions preventing you from measuring from the 9-12-3 positions. However, the restriction is that you must position the measurement devices at 9-12-3 as accurately as possible and that the system does not use the built-in inclinometers to calculate the position (in other words, you must check this yourself).

There is, however, one application when you must use the 9-12-3 method; during shaft alignment on-board seafaring vessels. This is because the inclinometers would move in conjunction with the vessel’s movements on the waves, potentially corrupting the collected measurement values. We, therefore, recommend using the 9-12-3 method as the inclinometers are switched off.

Method 2: EasyTurn

EasyTurn is a unique further development of the 9-12-3 method, with the freedom to choose at which clock position (which angle) you start collecting measurement values. With the help of some mathematics, we can also restrict the total measurement range to 40 degrees full rotation. From a practical point of view, this means that you can use this method where there is limited possibility of rotating the machines, due to the lack of space around the shafts.

This method is the standard-setting in most Easy-Laser shaft alignment systems (except XT660, which uses ”Continuous Sweep” as the standard method, see below).

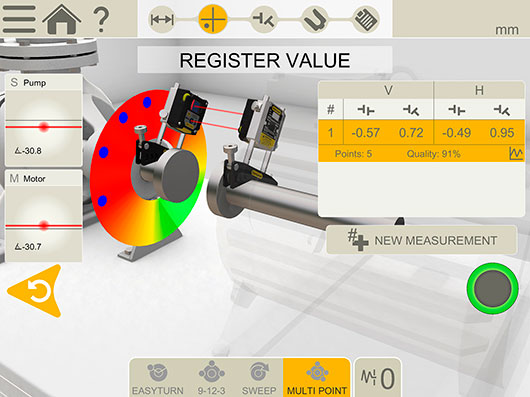

Method 3: Multipoint

Multipoint is, in turn, further development of EasyTurn. Multipoint also means that you can start collecting measurement values from any clock position (angle), and complete collection across as small a rotation as 40 degrees. However, as the name suggests, this method means that values are collected from more than three points.

This is advantageous if taking measurements from larger machines where it is difficult to rotate the shafts. Collect the measurement values across a shorter rotation to increase the mathematical probability of obtaining good measurement values. This method also gives a quality evaluation of the measurement series. The evaluation takes into account shifts in temperature, measurement direction, and a number of measuring points.

Method 4: Continuous Sweep

Continuous sweep can be described as Multipoint with automatic, continuous measurement value collection. In practice, this means that you can collect measurement values continuously with the measurement devices in motion. I.e. you start measurement value collection (at any clock position/angle) and then rotate the shafts without stopping, in one direction. Continue until you have collected enough measurement values to achieve a good quality calculation (quality evaluation is also performed here just as in Multipoint).

In the end, the shafts’ rotational center is calculated and presented graphically via images and text. This method is very useful in instances where it is difficult to stop the machines to take stationary measuring points, for example, when aligning large turbines.

We hope you now have a clearer picture of the various measurement methods and when best to use them.

The Easy-Laser XT Alignment App can be downloaded free of charge from the App Store and Google Play to try out.

by Ana Maria Delgado, CRL

We at LUDECA proudly share the excitement with our partners at Easy-Laser® for winning the Red Dot Design Award 2018 with their XT11 display unit.

The distinctive Red Dot is established internationally as one of the most sought-after quality marks for good design. Here are some of the things they considered in their evaluation:

• Degree of innovation

• Functionality

• Formal quality

• Ergonomics

• Durability

And yes, this is their second design award with the excellent development and capabilities of the XT11 display unit. They won the iF Design Award in 2017. XT11 has some smart functions, like the screen-lock button which prevents unintentional clicks on the touch screen when you move around the machine you measure. As an option, you can fit your XT11 with a thermal imaging camera, opening up even more possibilities to optimize your machinery for smooth operation.

Easy-Laser XT11 runs the XT Alignment app, which can also be run on iOS and Android phones and tablets. This is a unique feature in the alignment industry – the user can combine display units and different types of measuring units to suit their needs and budget – but will only have to learn one alignment program!

Congratulations to our partners at Easy-Laser for winning this great award for this excellent product!

Contact us if you would like to see the Easy-Laser XT11 display unit in action or watch the XT11 video.

by Ana Maria Delgado, CRL

An arc-second is a measurement unit for angle. It is often used in describing level and plumb.

1 arc second = 1/3600 degree = 0.000278 degree =0.0000048 inches/inch =0.0048 mils/inch = 0.0048 mm/m

1 degree = 17.347 mils/inch

1 mil/inch = 1 thou/inch = 1 mm/m (The metric-imperial relationship is purely a coincidence!)

A high accuracy machinist bubble level, a commonly used tool to check the level of baseplates and foundations, is typically 0.24 mils/foot (often mentioned as a “quarter of a thou per foot” in the field) = 0.02 mils/inch = 4.15 arc seconds.

by Daus Studenberg CRL

“Mil” and “thou” are the same. They are imperial measurements both are synonyms for 0.001 inches. This unit is normally referred to as a “thou” (which is short for a thousandth), or (particularly in the United States) a mil. Mil has its origins in the metric prefix “milli”, which is Latin for “one-thousandths”. The plural of a mil is mils and the plural of thou is thou.

by Daus Studenberg CRL