Steam turbine internal alignment applications require high precision, ease of use, and reliability. The Easy-Laser® E960 system is used to align diaphragms and internal components and delivers all these things.

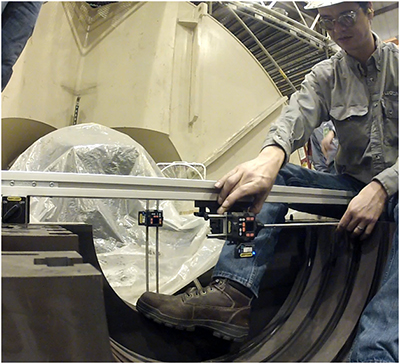

Setup is fast and simple. There is no need to precisely center your detector to the bore or the laser to the rotor to perform position checks. Simply orient the sensor into laser range, and the display unit does the rest to calculate the center. Your rotor positions are entered digitally for greater accuracy and speed of setup. Wireless components streamline the setup—no cables to get in the way!

Setup is fast and simple. There is no need to precisely center your detector to the bore or the laser to the rotor to perform position checks. Simply orient the sensor into laser range, and the display unit does the rest to calculate the center. Your rotor positions are entered digitally for greater accuracy and speed of setup. Wireless components streamline the setup—no cables to get in the way!

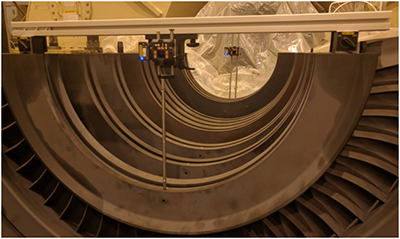

Take three points over 180 degrees on a bore just as you would with a tight wire, or use the multipoint measurement to find the center of bores and check for ovality.

The Easy-Laser E960 features an optional reference control sensor for greater reliability and precision. No more guessing whether your reference line (the laser beam), moved during measurement—you are in control of its position at all times. Even if the beam moves over time due to environmental factors, the reference control sensor allows the system to automatically adjust for such movement to ensure all your readings stay highly accurate.

Need to measure the flatness of the shell? Simply add the D22 rotating laser and flatness readings can be taken using the same sensor as the one you use for internal bore alignment. Both the top and bottom shells can be measured without having to remove the bolts.

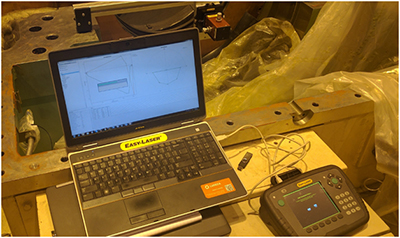

This system works with your existing processes. The Easy-Laser E960’s intuitive display allows for entry of diaphragm positions into your excel spreadsheets or takes advantage of the included Easy-Link software to present, process, and document the turbine alignment in one complete and easy to use package.

Filed under:

Alignment, Geometric Measurement by Daus Studenberg CRL