There are two primary types of accelerometers: one is the ICP (integrated circuit piezoelectric) having voltage output, and the other is known as a CLD (current line drive) type, with a current output. The standard ICP accelerometer has a nominal output of 100 mv/g and the output of a standard CLD accelerometer is 9.81µA/g.

Cable movement during low-frequency measurements with ICP accelerometers can induce triboelectric noise.

Triboelectric noise results when two materials are rubbed together creating an electrical charge between them. Triboelectric noise can be generated by flexing or vibrating the accelerometer cable during data acquisition. Such movement can result in friction between the cable’s various conductors, insulation, and fillers. This friction can generate a surface charge resulting in triboelectric noise. Vibration data collectors will measure the voltage generated by this effect. This can cause data integrity issues with acquired data. CLD sensors output current rather than voltage and are therefore not subject to the triboelectric effect from cable movement.

by Gary James CRL

Recently I visited a customer’s facility to provide onsite training for the VibXpert® vibration data analyzer they had recently purchased. Before we could get started collecting data, we needed to build the equipment hierarchy and measurement templates required. Once the database was created, we loaded routes into the VibXpert and proceeded to collect vibration data.

The first room we entered had two large belt-driven overhung fans. At first glance, it was obvious that one of the fans was running extremely rough. We collected vibration data on both fans and paused to review the results. We noticed that the 1× amplitude on the rough fan was over 1.0 inches per second peek. The local CM technician immediately commented that the fan should be balanced and his observation was correct when simply looking at the vibration data.

The room was full of clues that explained the cause of the fan unbalance. This facility processed and manufactured wood products. Large amounts of wood dust are produced and these fans were designed to ventilate a high dust area. Everything in the room was covered with wood particles and dust. The only question was how much had accumulated on the inside of these fans.

I asked if the fan could be stopped for a short period and the inspection door opened. My request was honored and the fan was shut down and locked out. Our examination revealed the fan blades had amassed substantial amounts of wood particles. The fan blades were cleaned and resulting in a pile of wood chips weighing about 5 lbs. The fan was placed back into operation and allowed to run for several minutes. Vibration data was recollected on the fan and the 1× amplitude had reduced to 0.1 inches per second.

Fans require corrective action to eliminate unbalance conditions from time to time. However, the cause of unbalance may simply be a buildup of foreign matter on the blades. This fan was being allowed to beat itself to death due to product buildup. This facility learned a few lessons from the experience. First, inspections utilizing the human senses (touch, hearing, etc) could have been used to determine that this fan was in need of attention.

Second, periodic vibration monitoring would have identified a need for maintenance on this fan. Third, if a fan is properly balanced, simply cleaning foreign matter buildup may reduce the vibration, prevent equipment damage and maintain the reliability of the equipment. Make sure that you utilize these three steps during your daily maintenance efforts on equipment.

by Dave Leach CRL CMRT CMRP

Advanced vibration analyzers like the VibXpert® have powerful analytical features that often go underutilized. One such feature is the ability to acquire continuous (live) vibration measurements. This can be utilized to check for measurement signal stability and quality. However, it can also be used for additional analytical troubleshooting as well. Continuous (live) vibration data can be used to determine if electrical energy (faults, etc.) is present in electrical motors. Set your vibration analyzer to continuous monitoring. Identify and watch the peaks in question.

Turn the motor off while watching the peak(s) in the measured data. Peak(s) that disappear immediately when motor power is turned off are related to electrical energy. The remaining vibration data is associated with rotating components within the equipment.

Continuous data collection can be activated in the VibXpert analyzer by selecting the Multi-Mode icon and then the Data Collection icon that will be used. Press the Menu key, select the display setup option and toggle continuous measurement to “Yes” (it is set to “No” by default). Alternatively, you can activate the live mode by keeping the “Enter” key pressed when the measurement starts. The actual data collection begins when you release the “Enter” key.

by Mickey Harp CRL

Guest post by Brad Loucks, Mechanical Engineer at Pioneer Engineering

In a condition monitoring vibration program, determining the appropriate intervals of data collection is just as important as the data that is being analyzed. Properly scheduled data collection intervals of equipment provide data analysts with a better picture of how equipment is performing over a period of time. Having a history of data is important for an effective condition monitoring vibration program and this is done by establishing correct data collection intervals.

Data collection intervals should be established and executed with purpose, not done randomly. To establish intervals, it is important to know and understand how the equipment works. Determining the appropriate time interval between collections is done by identifying how often the equipment runs, how fast it runs, and the application. The calculations are based on the estimated life cycle of the bearings but also the estimated amount of time it takes to go from a defect to a complete failure.

Collection intervals should be a routine function. Many times data collection falls behind because the collection person is too busy to collect the data. One of the most common issues that I have come across is that plants will begin to collect data and then the person collecting the data gets pulled to do other work and the data collection gets missed and becomes more random. This is a slippery slope in that it almost always leads to the data no longer being collected. Then when an emergency comes up such as a bad-sounding machine, the analysis has not been collecting history on the equipment but they have also been out of the analysis for so long that they have a difficult time remembering how to analyze. The history and interval are just as important for proper analysis as it helps to give the analyst a more accurate analysis by allowing them to see the progression timeline.

Bearings often do not fail in a predictable time span. If this were the case, vibration analysis could be overlooked and time-based maintenance could be used. A bearing can go from a known defect to catastrophic failure over the course of a few years or it can happen within minutes. The collection intervals are calculated so that not only can data be collected and the severe defects be identified, but also to identify when a defect has formed and allowed for a history to be built in order to watch the progression of the defect. This can aid in determining whether immediate action should be taken or if the defect is at an early enough stage where proper planning and measures can be taken to avoid an immediate shutdown and loss of production.

If the equipment is deemed valuable enough or if unplanned downtime is just out of the question, then calculated collection intervals are a necessity of a proper condition monitoring vibration program. Through proper maintenance, a condition monitoring vibration program can save a plant both time and money in reducing or eliminating unplanned downtime, as well as significantly reduce the possibility of injury or death of plant staff due to catastrophic equipment failure.

by Ana Maria Delgado, CRL

Guest post by Ray DeHerrera, Mechanical Engineer at Pioneer Engineering

Vibration analysts use multiple tools to predict a potential fault in a machine; from transducers to accelerometers, the toolbox for vibration analysts is continually expanding to allow for more comprehensive and accurate data collection and interpretation. One tool that is absolutely important to the data analysis process is knowing how your equipment processes data. Vibration analysts need to know how results are being derived from multiple calculations within your equipment. This allows for the development of an efficient collection history that will produce more accurate results.

The calculations attempt to translate data banks into a model that can then explain the events occurring inside of your equipment. Often times the computer-processed model may develop imaginary information, thus leading to more questions than answers. With basic background and knowledge of variables that may affect your post-processed data, your questions will start to be answered.

To introduce the initial creation of our mathematical model that is displayed upon our data collector or computer screen, (such as the time waveform or spectrum) we will explore commonly used hardware such as the transducer. In general, the function of the transducer is to convert one form of energy into another. A commonly used transducer for case-mounted readings is an accelerometer. The accelerometer mimics mechanical vibrations to produce a usable signal. The usable signal is so small that typically an internal amplifier will be needed for your data collector to harness the information. This process is the initial creation of our mathematical model of data, which has been created from a response of a mechanical device (transducer) sitting upon a machine and is now being converted to a digital signal that has been amplified.

Now our signal must be stored for further analysis. There are a number of vibration collector types and manufacturers. The collector is very similar to a computer giving it the ability to quickly process the original signal into various mathematical models. One must take the time to do their research before purchasing a collector and the associated software. Many desired post-processing and collection capabilities may be limited such as sampling rates. With a good collector and setup, your mathematical models will be accurate. The accuracy and consistency in your collections are key when managing your periodic collections.

The basic knowledge of how your equipment generates your post-processed model will make your time more efficient and your results accurate. The analyst will be able to identify data that is imaginary and pick out what is real. Take the time to understand your hardware and how your computer generates each model.

by Ana Maria Delgado, CRL

Have you ever collected data and uploaded the data back into OMNITREND® only to realize that you have duplicate data in your database? As a technician, you are pressed for time and your boss needs that report like yesterday. Every so often, when uploading the data you can get distracted by other people or from trying to juggle too many things at once, and you inadvertently upload the data twice.

You can delete the duplicated data without having to delete each one by one! Here’s how:

• Click Tools

• Select Report

• Select OMNITREND Web

• Click OK

• Click Database

• Select Database Utilities

• Select Data cleanup

• Once the data cleanup is complete click Close

• In OMNITREND click Database

• Select Database Utilities

• Select Compact & Repair

Once the Compact & Repair process is complete you can go into Machinery Manager, drill down into your database, select the task and then click the Edit Meas. Data tab on the right-hand side of the screen, and you will notice the duplicate data has been deleted.

by Myrna Michel

For the highest confidence level possible while doing predictive vibration analysis work, the location and placement of your sensor are crucially important to you. However, sensor placement is sometimes a trade-off between time, safety, and precision.

Most equipment is mounted with the shaft oriented horizontally to the ground and the analyst must decide whether to take a radial horizontal measurement, radial vertical measurement, a shaft axial measurement, or some combination of the three. If the analyst has the time, there is good reason to take all three positions. When it comes to analysis, an analyst can always choose not to view data he or she has, but can never choose to view data he or she did not collect.

Where should I place my sensor? The answer to this question should come from a focused consideration of what each possible position offers to the overall analysis effort. The fundamental consideration in placing your sensor is that the vibration signal from the component or components of interest should take the path of least resistance to the sensor. This should be coupled with thought given to how every likely defect frequency presents itself relative to direction.

Many fault diagnoses are determined, or the level of confidence enhanced, by relating one location result to another. For example, a high 1× vibration in the horizontal direction on a direct drive center-hung rotor could mean a lot of things, if taken by itself. But if this information is coupled with the additional hypothetical data below:

- The axial vibration is also high: then possible misalignment or bent shaft becomes likelier.

- The axial is low, but the vertical is 1-½ times as high as the horizontal: Now looseness is probable.

- The axial is low, and the vertical is ½ of the horizontal: probable unbalance.

- The axial and vertical are both very low relative to the horizontal: In fact, the horizontal is 75 to 100 times the axial and vertical! Almost unquestionably there is a resonance problem.

In all of the above scenarios, a phase and visual inspection are required to deliver a truly confident diagnosis, but the directional aspect of data analysis is clearly shown.

Trending puts still further demands on the analyst by requiring each successive measurement to be taken in exactly the same place as before, to the extent possible. For parameters to be reliably trendable, operating states and data collection states need to be the same from measurement to measurement.

A real danger for the analyst using portable vibration data collectors lies in the monotonous repetition of placing a sensor hundreds of times in a day of data gathering and becoming careless when making that next placement. If feasible, routes should be kept small enough to help avoid the human factor. It’s too easy to daydream while collecting data. A route under 200 points helps keep the monotony away. The analyst should focus on both safety and data collection precision throughout each route. Happy defect hunting!

by Mike Fitch CRL

Proper location is very important when collecting vibration measurements on a belt system. If possible, one reading should be taken in line with the sheaves and one reading perpendicular to them on each bearing. Vibration data resolution should be taken into account so that proper separation between belt and driver frequencies can be obtained. Care should be taken to ensure proper belt alignment as well. A laser pulley alignment tool provides the most efficient means to properly align belts. Another issue is how the belts are installed. Was the equipment loosened and the belt put on properly? Were the belts instead rolled on by force, creating potential issues? Have you ever seen a Vee belt running upside down? This is usually caused by the cording in the back of the belt being broken often caused by rolling on the belts. Are sheave gauges being used to check the sheaves for wear? In some cases, the cost of a belt is more than the cost of a new sheave. These are just some of the things to consider for proper installation, maintenance, and identification of belt-related problems.

Don’t just assume that belts are simple and do not require best practice actions for proper operation.

by Gary James CRL

The scenario: You have just been informed that a corporate reliability initiative has begun. Your new assignment is to implement a vibration analysis program. You are disconcerted because you are not sure how to implement this new assignment or where to seek help. Many organizations implement a reliability initiative because their competition has already done so or management has become convinced of the financial value that can be gained from it. Unfortunately, as with most things in life, the devil is always in the details.

Company culture plays a critical role in the successful implementation of a reliability program. This shouldn’t be underestimated. Some companies implement program after program, each with the best of intentions. The objectives are always to increase operating efficiencies, achieve cost reductions, capacity improvements, shrink required manpower, etc. Many of these efforts fail after a few months because the program is replaced by something new, key management individuals did not support it, inadequate funding was provided, proper awareness was not instilled, and many other reasons. The new initiative falls into an abyss and is quickly forgotten.

Most seasoned employees who work in these organizations have seen this happen time after time over their careers.

Many employees and managers thus adopt a “wait and see” approach. This trait is learned after years of seeing efforts start and quickly fail. Why join the “flavor of the month” club and devote focus to something that will soon be replaced? It requires less energy to wait and see if the new program will remain a company priority and become successful. The financial value to your business is clear, but will only be realized if the program is correctly implemented and sustained. Senior management has to ensure that everyone understands this effort is not a passing fad. Key signs of support must be given with results-driven implementation.

Don’t let the vibration analysis program and other reliability efforts become a “flavor of the month” effort.

Become the champion that promotes the value of these efforts and helps to ensure the results are implemented.

Doing so can reap great rewards for yourself and pay great dividends for your company. Seek support and advice from technology vendors, co-workers, and the many resources available. You are not alone! Many individuals have been where they are now or faced the same challenges within their organization.

The road to success can be long and difficult to traverse. However, with proper implementation, persistence, and senior management support you can get there. Persevere!

by Dave Leach CRL CMRT CMRP

New portable and online-monitoring systems help extend the value of vibration monitoring into the heaviest of industrial operations. Here’s a look at how users avoided serious motor failure in mining and detected a critical bearing failure in paper-pulp production by using the right vibration products at the right moment.

Case Study #1:

A Phosphate mine is garnering big returns by monitoring numerous pieces of processing equipment with online solutions from LUDECA. The mills use several low-cost VIBNODE® online systems. The VIBNODE is a comprehensive entry-level online monitoring system that allows the end-user to access customized spectrums and time waveforms from a remote location. The system will notify the end-user via email or text message when the vibration level exceeds an alarm band.

The new monitoring system has helped the mine’s vibration group catch several problems with a newly rebuilt drive motor. The waveform showed a fuzzy amplitude modulation that increased and decreased with every RPM.

A look at the acceleration spectrum indicated a large amount of high-frequency noise well over 1g. Upon inspection, several internal retaining bolts were found to be backing out and contacting the frame of the motor rotor. The bolts were tightened to torque specifications, which was believed to have solved the problem. A week later, however, the problem reemerged as the bolts had once again backed out and began to rub. The bolts were again torqued to specification, but this time with an application of thread locker, which held the bolts in place.

Had this problem not been identified by the fuzzy waveform and a high-frequency acceleration band alarm from the VIBNODE system, the errant bolts would have quickly eaten into the motor rotor and caused a catastrophic motor failure. The motor rebuild or replacement is valued at well over $100,000. And losses to production would have been many more times this amount.

Case Study #2:

Low-speed equipment turning below 40 RPM is often difficult to analyze because of the low energy it produces. If there is not much energy, there is often not much to see. For this reason, the dynamic range of a vibration analyzer/data collector and its signal-processing quality become critical for low-speed machine analysis. Recently, a pulp mill using a VIBXPERT analyzer from Ludeca took a spectrum and time waveform on a slow-speed 35 RPM roll. The VIBXPERT is a portable, lightweight, 2-channel, FFT data collector/vibration analyzer for monitoring and diagnosis of machine conditions. As a data collector, VIBXPERT records all forms of machine vibrations, bearing conditions, process data, and visual-inspection information.

Because of the dynamic range of the VIBXPERT, the mill’s maintenance technicians were able to see a repeating pattern in the time waveform. The recurring pattern was present for every RPM and would increase slightly, then disappear for about three-quarters of the roll’s revolution. A delta cursor was placed on the repeating pattern and the source frequency was 420 CPM. This worked out to be the frequency of the inner race. A 25,000-line spectrum was also collected with a bandwidth of 7.5 CPM per line of resolution. The amplitude was very low below 0.0008 inches per second, yet a definite harmonic pattern appeared. The main harmonic pattern was at 420 CPM, with each peak having another underlying pattern of 35 CPM sidebands. The frequencies represented the inner race and roll RPM. Had this data been taken using a conventional spectrum with a resolution of 6400 lines or even 12,800 lines, this low-frequency/low-energy event would have looked like a spectrum ski slope and been ignored.

Upon removal of the bearing, a crack in the inner race was plainly visible. There was evidence the inner race had begun to walk around the shaft. If the bearing had been left in service it would have damaged the shaft and required that both the shaft and bearing be replaced. Instead, only a minimal two-hour shutdown was required to replace the bearing. Thanks to early detection, the cost of replacing a roll was averted, as well as saving the eight or more hours of lost production that a roll replacement would have required.

by Greg Lee

Every analyst has a few things they really don’t want to hear during the course of their work. These comments often indicate that proper maintenance activities have not been performed on the equipment, or convey unrealistic expectations of the analyst’s abilities. For instance:

- “It has always run like that!”

- “It really was making a noise before you arrived.”

- “We don’t have time to change the bearings. Just balance the machine so we can run it.”

- “How long will it last?”

- “Those bearings are brand new so I know they’re good.”

- “Yeah, we just use a torch to heat bearings to install them.” Use an EDDYTHERM® induction heater with automatic demagnetizing to properly install your bearings.

- “We don’t have a bearing heater so we use a pipe and hammer to drive the bearing on.” Use an EDDYTHERM induction heater with automatic demagnetizing to properly install your bearings.

- “All we collect are overall vibration values, they tell us everything we need to know.”

- “It doesn’t take us long to change belts cause we just roll them on.” Very bad practice! Use a laser tool like the SHEAVEMASTER and loosen the feet of the motor before installing the new belts.

- “We don’t use no fancy alignment tool. All we need is a straight edge.” A recipe for disaster! Get a good laser shaft alignment system like the SHAFTALIGN® —the money this will save in lost production and unnecessary repairs will more than pay for itself, not to mention the time saved for the analyst who can now dedicate himself to finding other more complex vibration problems.

- “My screwdriver does not confirm your analysis!”

- “You found the problem. Now go fix it.”

- “I didn’t realize you needed training.” Sign-up for a LUDECA vibration analysis training class.

- “I didn’t realize that this CM technology would create so much work.”

- “We need you to stop using that CM technology and turn wrenches this week.”

- “We didn’t realize you had identified and created a work order to fix that problem before it failed.”

No doubt you’ve heard a few more! Feel free to share them with us.

by Gary James CRL

As a vibration monitoring program becomes more mature, the number of monitoring points on a machine and throughout a facility can increase to a very high number. These additional monitoring points are required to identify potential failures and maintain a world-class reliability program. Unfortunately, these additional measurement points usually result in an increase in the time required to complete the data acquisition (routes).

Consider using a triaxial accelerometer with a magnetic base along with a vibration analyzer such as the VibXpert® II. This combination will allow the acquisition of multiple measurement points simultaneously and guarantee that proper data is being collected. You will be able to achieve the desired results with the highest analytical accuracy and greatest labor efficiency.

by Mario Rostran CRL

- Shaft speed of machine being analyzed

- Type of bearings involved (sleeve vs. rolling element)

- Rolling element bearing part number(s) and manufacturer(s)

- Internal configuration of equipment

- Machine History

- Proper data collection location

- Proper sensor to use for data collection

- Proper data collection setups to ensure correct data is collected

- Is the primary energy sub-synchronous, synchronous or non-synchronous?

- If the time waveform is collected in acceleration then what is the “g” level?

by Gary James CRL

Proper vibration data collection and diagnostics require knowing the accurate operating (turning speed) of monitored equipment. The most common tools used for measuring equipment turning speed are a tach (tachometer) and strobe (strobe light). If a means to determine equipment speed is unavailable, then an advanced vibration analyzer like VibXpert® may have additional capabilities to help you make a precise determination.

Set your vibration analyzer to acquire a velocity spectrum via the Multimode capabilities. A lower fmax is ideal because that is where the turning speed will be identified. Also, be certain that the lines of resolution (LOR) selected are high enough to accurately measure all of the frequencies around the turning speed. For example, improper LOR selection may result in the driver (motor) and driven (fan, etc.) frequencies being combined/merged together in one peak. This can make operating speed determination inaccurate or impossible. Please note that with higher LOR settings the data will take longer to collect because additional data is being acquired by the vibration analyzer. The number of averages should be set to a minimum of four to make certain any non-periodic energy is filtered out during data collection. Once data collection is complete, a cursor can be placed on the first high peak which usually indicates the turning speed of the asset.

Also, Multimode data collection can be set to a continuous mode allowing the data to be viewed live as it is collected. Once stabilized, the cursor can be placed on the spectrum to determine the turning speed of that asset as described above.

by Mickey Harp CRL

Maintenance departments are often expected to collect data on critical equipment in a consistent manner in order to monitor the efficiency and maximize the life of such equipment. Doing this manually can pose safety or health hazards to those responsible for collecting the data. The solution is to install permanently mounted sensors with wiring directed to a termination/switch box.

There are several ways to permanently mount the sensor to the machinery, but the most common are:

- Adhesive: This consists of using a strong epoxy-like adhesive that will allow for a sturdy mounting. It is very critical that the two surfaces be thoroughly cleaned with a steel wire brush to remove any paint and/or corrosion that can compromise the integrity of the bond between the sensor and the machine.

- Drilling and tapping: This consists of drilling a hole into the casing of the machine and then tapping the hole to the thread of the stud included with the sensor. This last method is the preferred method as it will guarantee a completely solid bond between the sensor and the machine

For whichever of the above methods is chosen, cabling will have to be routed. It is important to route the cable through the conduit so that it is protected from harsh temperatures or exposure that can potentially cause damage. When possible, utilizing a cable trough will help keep the cabling organized and away from any of the rotating components of the machine. Labeling the cables will guarantee that the final wiring in the termination/switch box becomes a smooth process. Once the routing of the cable is completed, thanks to the labeling of the cables, the wiring to the termination/switch box becomes very simple. Once the permanently mounted sensors are installed, the analyst in charge of the Condition Monitoring program can safely collect data with the help of a capable data collector such as the VibXpert® II. This will help the plant maintain a world-class reliability and maintenance program while ensuring the safety of its employees.

by Mario Rostran CRL

Vibration analysis can detect the following bearing fault conditions:

- Defects on raceways

- Defects on rolling elements

- Defects in cage

- Looseness in housing

- Excessive clearances

- Bearing turning on the shaft

- Misaligned bearing

- Cocked bearing

- Lack of lubrication

by Trent Phillips

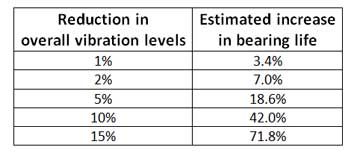

Have you considered the costs associated with allowing your equipment to continue operating at excessive vibration levels? Have you considered the benefits of reducing the vibration levels of your equipment? The reliability and cost benefits of reducing the vibration levels of your equipment may surprise you.

Below are some examples showing the estimated increase in bearing life attainable by reducing the overall vibration levels in equipment.

Do not deny your facility the increased equipment reliability and decreased maintenance cost associated with reductions in vibration levels.

by Trent Phillips

Alarms can save time and assist in the notification of impending issues when analyzing vibration data within your Condition Monitoring software. Of course, the correct alarms must be set in order for the analyst to perform his or her job correctly. Too many times the incorrect levels are set for alarms causing a machine to either be constantly in alarm or for the monitored conditions never to reach the required levels to alert the analyst of an issue that should be alerted.

OMNITREND® software has many different alarms that can be configured to assist the analyst in performing their job. Over time the running condition of a machine will change and it is important to make certain that the alarms are also checked and tweaked if needed. An alarm value might need to be changed many times over the life of a machine.

OMNITREND has a feature that allows the end-user to view the collected data and adjust or set alarms according to the machines’ vibration levels. These “smart alarms” should be set after collecting data for at least three months. The three-month period allows the analyst to view how that machine has operated over that time period.

The ability to display many different data readings at once on the same screen is provided. This allows for smart alarms to be configured using the vibration levels from the machine. Do remember that a machine’s vibration signature will change over time. Be certain to update your alarms with that information in mind.

If you have any questions or need assistance configuring alarms within OMNITREND please contact us. Our hardware and software support is offered at no charge to our valued customers.

by Mickey Harp CRL

What are some of the most common techniques that should be used every day in a vibration analysis program?

-

Spectrum Analysis

Spectrum Analysis is used to help identify the normal operating frequencies of a machine. Additionally, the defect frequencies and their characteristics can be routinely identified.

-

Waveform Analysis

Waveforms are one of the most overlook analysis tools. Waveforms can be used to identify fault patterns of equipment defects and help determine the severity of the defect.

-

Trend Analysis

Trend Analysis is a critical part of any vibration analysis or condition monitoring program. Trend analysis will help identify fault trends in equipment that may have gone unnoticed otherwise. Also, trend analysis can be used to help identify the severity and rate of progression of identified fault conditions.

-

Band Alarming

Carving up the entire spectral range into significant bands and setting alarms to indicate when a problem might be beginning is a good way to optimize the time of analysts and the efficiency of a vibration analysis program. This method can prevent fault conditions from being overlooked.

-

Shock Pulse

Shock Pulse is a way of harnessing the resonant properties of sensors to gain valuable defect information. This method can be used for early warning of bearing defects and to identify lubrication-related issues.

-

Envelope Demodulation

Enveloping is a generally valuable early detection method for anti-friction bearing defects and specifically very valuable for detecting such flaws in low and very low-speed equipment.

-

Phase Analysis

Phase analysis can be incorporated into everyday route data collection. This data can be used to distinguish between different faults that may have similar characteristics.

by Trent Phillips

Have you ever been notified by operations that a machine is experiencing an issue and asked to quickly help determine the nature of the problem? Does this happen repeatedly on the same machine? Even around the same time of day or week?

Have you considered that process changes could be affecting the equipment? Changes in flow rate, operational speed, temperatures, etc. can affect the normal operation of a machine. The effects can be increases in vibration levels, failures, etc.

Operators may be changing the operational parameters of a machine or process at the start of a shift or at certain times. These changes could be affecting the ability of the machine to operate normally. This could explain why the machine is experiencing problems and why the problems occur at certain times of the day or week.

Some studies have revealed that between 60% – 70% of equipment failures are preventable by operators.

Operational parameters should always be monitored and considered as possible causes for equipment issues.

by Trent Phillips