Strobe lights are an inexpensive tool typically used to determine the operational speed of the equipment. Strobe lights should be readily available to vibration analysts and maintenance mechanics. A strobe can be used as a proactive tool for many things. For example, visual inspection of belt damage (slippage, wear, etc), coupling damage, loose components, and much more can be identified with this handy tool, while the equipment is running. Don’t overlook the value a strobe light can provide beyond just the simple determination of the operational speed of a machine. But keep two things in mind: SAFETY must be first and foremost in your mind at all times when using a strobe light. Since a strobe can appear to “stop motion” on moving components, the temptation to touch the object you are looking at can be strong at times. Avoid this temptation and always stay focused on what you are doing. Also, people prone to epileptic seizures triggered by flashing lights should avoid exposure to a strobe light.

by Trent Phillips CRL CMRP - Novelis

As Published by COMPRESSORtech2 Magazine October 2016 issue

by Karl Hoffower – Condition Monitoring and Reliability Expert for Failure Prevention Associates

Combining ultrasound and vibration sensing adds precision to recip valve analyses

Over the past decade, ultrasonic condition monitoring of reciprocal compressor valves has become more widely known. However, it does not seem to be widely used.

Ultrasonic testing measures high-frequency sound waves, well above the range of human hearing.

These ultrasound devices record the high-frequency signals for analysis later. Trending valve cap temperatures is the most common condition monitoring technique for monitoring

compressor valve health.

Ultrasonic testing of compressor valves and vibration monitoring of rotating components is an informative, preventative-maintenance practice. Compressor valve deficiencies with opening, closing, or leaking may be diagnosed using the ultrasound recording functions.

Steven Schultheis, a Shell Oil Co. engineer, addressed the issue in a paper presented at the 36th Turbomachinery Symposium in Houston in 2007.

“Trending valve temperatures have proven to be valuable in identifying individual valve problems, but are most effective if the measurement is made in a thermowell in the valve cover.” Schultheis wrote. “Ultrasound has proven to be the preferred approach to the analysis of valve condition.”

Failure Prevention Associates completed an experiment with a major midstream gas transmission company to see if this type of condition monitoring tool can effectively find fault conditions well before another technology is used.

Ultrasound meters (such as the SDT270 from SDT Ultrasound Solutions) have digital readouts that indicate the level of ultrasound detected. These devices have been used for decades to “hear” air, gas, and vacuum leaks. The intensity or amplitude of the signal is expressed in decibels — microvolts. (dB[A] μV). The dB(A) is a common intensity unit for sound intensity; μV designates the engineering reference unit being used with a piezoelectric sensor.

Converting an airborne ultrasound detector with a contact sensor allows a technician to monitor what is happening inside a machine, whether it is a bearing, steam trap, or valve.

Ultrasound detectors are designed to operate in a specific and narrow frequency band. Then through the “heterodyning” step high frequency sounds down into an audible format that the technician can hear through headphones. During the heterodyning process, the quality and characteristics of the original ultrasound signal are preserved.

Read full article complementary-condition-monitoring-boosts-reliability-article

by Yolanda Lopez

As Published by Maintenance Technology Magazine August 2016 issue

Clinging to a single approach that made economic sense for your plant ‘back in the day’ could be an expensive strategy.”

Overall values are the most common measurements and calculations used in vibration analysis. What’s more, some reliability and maintenance programs rely solely on them. The goal is to remove monitored equipment from service once the overall vibration level exceeds a certain threshold. Although this approach would appear to be quite cost-effective, in reality, it frequently isn’t. In fact, overall vibration monitoring can become extremely costly for a facility.

If you are asking yourself questions such as: What should you do once an overall vibration level exceeds your target amplitude and the equipment is removed from service? Who should collect routine vibration data? What other valuable condition-monitoring data might be missing? Or how do you motivate others to take corrective actions? then this article is definitely a must-read.

by Trent Phillips CRL CMRP - Novelis

How do you obtain the desired return on your assets? Availability, maintainability, and reliability are foundational elements required for a proper return on your equipment. Condition Monitoring is a tool that can help you build these elements and obtain the desired returns. Condition Monitoring can be completed while equipment is running to maximize uptime and help provide better overall reliability. Conditional changes can be identified before functional failures that result in downtime occur, preventing other unwanted consequences.

Unneeded work can be avoided (unnecessary PMs, failures, etc.), and better planning and improved scheduling achieved through CM.

Use Condition Monitoring as a means to build a solid foundation for your facility!

by Trent Phillips CRL CMRP - Novelis

May 2016 · Plant Services Magazine

Like a lot of reliability engineers, Joe Anderson, former reliability manager at the J.M. Smucker Co., appreciated – in theory – that precise pulley alignment is critical to preventing vibration problems and ensuring successful operations.

My understanding was, ‘Yeah, we need to do it,’ ” Anderson says. “But you always have these excuses.”

When the Smucker’s plant at which Anderson worked launched a dedicated vibration monitoring and control program a year-and-a-half ago, though, Anderson quickly became a convert to making precision alignment a priority.

The plant purchased a vibration analyzer (VIBXPERT®) and laser alignment tool (the SheaveMaster® Greenline) from Ludeca to help aid in identifying machine defects that appeared to be linked to vibration caused by misalignment. Laser alignment allowed for correcting vertical angularity, horizontal angularity, and axial offset – the three types of misalignment – simultaneously. Whoever was using the laser alignment tool, then, could be sure that adjustments made to correct one alignment problem didn’t create an issue on another plane.

Read the entire article to learn how J.M. Smucker Co. made precision alignment a priority: Get your alignment in line: Don’t jiggle while you work

by Ana Maria Delgado, CRL

Guest post by Karl Hoffower – Condition Monitoring and Reliability Expert for Failure Prevention Associates

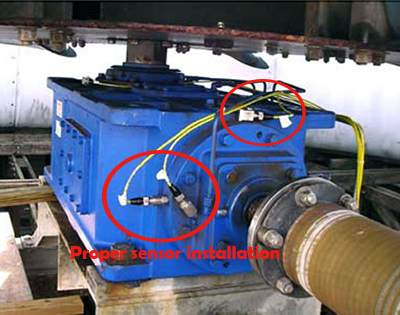

Location and placement of your sensors are crucially important when doing predictive vibration analysis.

1) Below is an example of proper sensor installation on a cooling tower gearbox. These two sensors are placed in different directions to follow both the gearbox vibration as well as indicate if the fan blades become unbalanced.

Read Vibration Sensors for Cooling Towers case study from CTC for details on proper sensor installation on cooling towers.

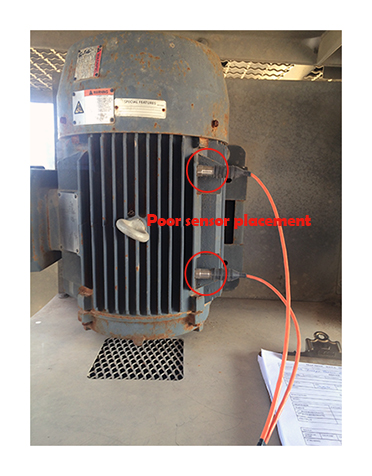

2) This example of poor sensor placement is on a vertical motor using a belt drive for a fin fan.

PROBLEM

- The vibration sensors pictured on the left are attached to one of the motor fins. Watching these sensors, one could visually see the fin and sensors oscillating as if on a trampoline.

SOLUTION

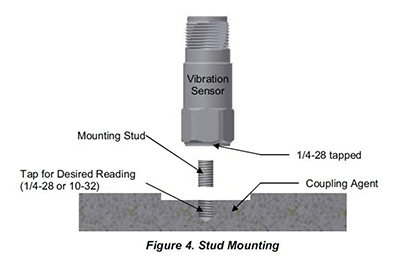

- The choices are to face, drill & tap (see figure #4 below).

- The other option would be to epoxy a mounting pad to the bearing housings. Then screw the sensor into the mounting pad.

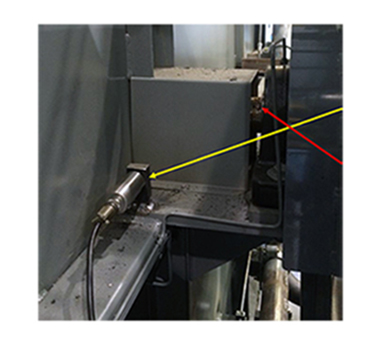

3) Another example of poor sensor placement on a 4-20mA shutdown switch on a gas recipient compressor at a facility in Texas.

PROBLEM

- The vibration sensor (yellow arrow) is a 4-20mA accelerometer used for asset protection in an automatic shutdown setting. It is monitoring the overall vibration levels emanating from the bearings and shaft (red arrow).

SOLUTION

- The better choice would be to use a mounting pad attached to the pillow block bearing.

by Yolanda Lopez

Does your maintenance staff have to wait on parts, wait for the equipment to be available, search for tools to do their job, work lots of overtime, travel long distances to the job, etc? Most maintenance staff work in pairs. This means that when you see one of your maintenance staff struggling to do his job, then his counterpart is struggling as well. What is the result? You may have a hidden cost (twice the labor) that you did not realize!

What can you do to avoid this? Make sure that your work is correctly planned. Job plans should be created, and be accurate and available. The required parts should be staged once the work is planned. Machine drawings, special tools, permits, etc., required to complete the maintenance activity should be identified in the job plan and be available as part of the job kit. Once all of this is done the work should be scheduled. These steps will help your maintenance staff focus on work and not on searching for the resources they need to complete their assigned maintenance tasks. You will save money and have more reliable equipment.

by Trent Phillips CRL CMRP - Novelis

Maintenance and reliability professionals track many key performance indicators (KPI’s) to measure the success of their efforts. These indicators can be overwhelming but are necessary to confirm the proper direction and achievement of desired results.

It is important that your CMMS (computerized maintenance management system) has the ability to categorize work orders. Condition monitoring work orders should be categorized by main types and by sub-types (vibration, lubrication, thermography, ultrasonic, electrical, etc.) upon creation within the CMMS.

Your CM and Reliability team should actively track condition monitoring work orders by total created, their type (vibration, lubrication, etc.), status (in process, scheduled, completed, etc.), the average length of time to completion, rejection results, and so on.

These indicators will allow you to ensure that a healthy amount of CM work is available and that this work is given priority, being properly planned, scheduled, and executed. It does no good to detect and report a conditional change in equipment only to have it ignored, not properly repaired, and then result in a functional failure.

Additionally, technology alarm status can be compared to open corrective work orders in your CMMS. For example, a corrective work order should exist addressing each severe alarm condition (red) reported by a CM technology. If a corresponding work order has not been created, then you should ask “Why”? Is it due to a bad technology alarm? Did the CM analyst miss something or fail to report the condition or repair? Or did the planner or scheduler simply overlook or ignore it?

Monitoring these indicators can help ensure that your CM program is providing continual results that will move your reliability efforts forward.

What indicators do you track to determine success with condition monitoring efforts within your company?

by Trent Phillips CRL CMRP - Novelis

As Published by BIC Magazine December 2015 issue

A world-class reliability program is not achieved overnight, yet you must start somewhere. Your first step is to vest your entire human capital in its success. Reliability is a culture, not a goal, and it flows from the top down.

Therefore, executive sponsorship with integrity and enforcement is a must. Obtain buy-in to the culture of reliability from everybody in your organization, or the effort is doomed to fail. Start with this realization, and your reliability effort will ultimately succeed, and you and your stakeholders will reap its rewards.

The reliability workflow must be well organized and underpinned by a Computerized Maintenance Management System (CMMS). Let’s look at how it works in a world-class program.

Ultrasound analysis detects a bearing fault in a critical motor early in the P-F curve. The analyst enters this data in the CMMS and trends it. The analyst decides to request a work order with recommendations. This is Stage 1 in the work order process.

The work order is now reviewed by both maintenance and operations, thereby ensuring buy-in from operations as well. This is Stage 2. This review process ensures only truly needed or valuable work is approved. Also, older open work orders can be combined with this one to further streamline planned activity on the asset. For instance, an earlier work order was created to align the machine, but the work was never carried out, resulting in the bearing damage the ultrasound analyst has now detected. The review process would catch the older open order and add it to the present order. This would prevent the millwright from going out to align the machine tomorrow only to have a repair technician go out the following week and repair the motor but do no alignment on it. This review process tries to eliminate inefficiency, duplication, and detrimental work sequences.

Stage 3 assigns the work order to the maintenance planner for action. Only approved and truly necessary work enters the planner’s backlog. The planner ensures work is properly prioritized. Two things are needed: The criticality ranking of the asset (ascertained from systems’ criticality analysis) and its operational criticality. Both of these factors can be multiplied together to create a more accurate prioritization of the workflow. The planner creates a new work plan if needed and should consult with maintenance supervisors and technicians; valuable insights may be gained into what parts, tools, and equipment should be specified in the work plan. Next, the planner orders the maintenance, repair and operating materials (MRO) spares, and tooling required to complete the job and verifies the parts are available and kitted (best practice). The planner should not concern himself with scheduling.

Now on to Stage 4: assignment to the scheduler. The scheduler allocates the HR and necessary time to accomplish the task, with a cushion for unforeseen complications. He too should consult with the maintenance supervisor and technicians to obtain cooperation and buy-in to the schedule. Coordination with operations is crucial. Operations “owns” the equipment and must sign off on the schedule to bring the asset down.

Stage 5 assigns the order to the appropriate maintenance and electrical supervisors, who in turn assign specific tasks in the work plan to their respective repair technicians, electricians, and millwrights, and verify MRO spares has delivered the parts kit to the proper location.

Now the work order enters Stage 6: the work execution phase. Once the technicians have completed the work, they report to their supervisors, who return the asset to active duty status in the system. Operations is notified the asset is ready for service, and MRO spares is notified of any unused parts and supplies that should be returned and reintegrated into the MRO spares inventory. Technicians and supervisors should feed their observations and data into the CMMS system.

Stage 7 sees the ultrasound analyst performing follow-up data collection on the asset to ensure all is well. The work now goes back to the planner to be formally closed. This ensures all important data has been accumulated and distributed within the system, enabling key performance indicators to be updated.

As good data accumulates, reliability engineering will use it to improve the entire reliability and maintenance process, discover frequent failure patterns, identify training needs, drive out defects, streamline production and help to improve the design process. As the plant becomes more efficient and productive, greater resources can be allocated to defect elimination and strengthening condition-based maintenance technologies, further impelling the transition to a proactive, reliability-centered culture. Reliability is a never-ending journey of continuous improvement.

by Alan Luedeking CRL CMRP

In today’s world, video platform is the way to accomplish effective visual knowledge and a learning mechanism in many organizations. With the use of video, one not only is able to promote products and services but one can also strengthen a culture and demonstrate how-to scenarios easily and quickly.

LUDECA believes in communicating visually to help customers educate and train their personnel on precision skills. For this reason, we are pleased to announce the release of our new microsite www.LudecaVideos.com, which features a Shaft Alignment Know-How series plus a Know-How series for Vibration Analysis and Balancing. The video site features basic terminology, fundamental concepts, advanced measurements as well as product demonstrations. The videos are indexed by category but also searchable by keyword.

We felt there was a need to go back to basics and help educate on precision skills and related technology to improve asset reliability. Following the Uptime Elements™ holistic approach to reliability, alignment and balancing are key components of your asset condition management (ACM) program. We are happy to offer these videos to our customers for their personnel to access and for use in their training programs. We hope this content assists them and others in either improving their reliability program or in getting one started and leads to world-class reliability programs,” —Frank Seidenthal, president of LUDECA.

We encourage you to visit www.LudecaVideos.com and see for yourself the value behind each video.

by Yolanda Lopez

Have you ever been asked “How much longer will it run” or “Can we make our production schedule” or other ‘crystal ball’ type questions? These types of questions can be very difficult or virtually impossible to answer. They often place a reliability professional in a difficult position.

Some future indicators are (or should be) available to the organization that will help you answer the above questions when asked. Four of those indicators are:

- Preventive Maintenance (PM) Completion Rate

Low PM completion rates directly correlate to increased future equipment maintenance work. High PM completion rates mean that needed equipment maintenance is being completed and future maintenance issues will be avoided. - Ready to Work Backlog

This is an indicator of preparedness and efficiency to complete maintenance work. - Outage Schedule Compliance

This is a very important metric to track and is an indicator of future maintenance work. A lack of adherence to outage schedules creates deferred equipment maintenance. This results in increased risks and the likelihood that equipment performance will decrease at a future time, leading to lower capacity, increased downtime, and greater expenses. - Equipment Asset Health Reporting

Proper utilization of condition monitoring technologies like vibration analysis, IR thermography, lubrication analysis, ultrasound, and others are a proactive strategy to ensure that hidden failures become known and corrected before they result in equipment downtime or other unwanted consequences. Tracking these indicators together can provide insights into future asset health. A lot of “red” assets from these technologies will result in future unwanted equipment maintenance and unwanted downtime if corrective action is not taken. Additionally, this can be used to help prioritize equipment maintenance efforts if a good critical equipment ranking system is in place.

by Trent Phillips CRL CMRP - Novelis

Certain technologies have been used for a very long time to identify corrective actions required to keep equipment operational and reliable. Vibration analysis, ultrasonic monitoring, infrared thermography, motor condition evaluation, and lubrication analysis are examples of these technologies. Many terms have been used to describe their usage within a facility. One term often used is “Predictive Maintenance”. Unfortunately, this term can be used in the literal sense with dire consequences.

Many facilities mix all of the required ingredients together to create a successful maintenance and reliability program. Regrettably, many others fail in their efforts. Two of the primary elements for success are predictive maintenance and work execution. The predictive maintenance effort may be quite effective at identifying conditional changes in equipment that should be addressed before functional failures occur. Those efforts will not be fruitful if the results are not executed. The predictive maintenance team has to generate work that is planned, scheduled, and executed. If the results of their efforts are not executed, then the facility will plainly predict costly failures that will be experienced by the facility. Basically, the effort will shift from “Predictive Maintenance” to “Predictive Failures”.

Make sure your facility is not predicting failures. Make certain the results of the predictive maintenance technologies are executed before conditional changes result in equipment failures.

by Trent Phillips CRL CMRP - Novelis

One of the big problems I’ve seen people run into when doing alignments is a lack of repeatability due to high vibration from nearby machinery. It’s obviously pretty difficult to align something that’s moving several thousandths. There are still ways to get accurate readings with some laser alignment tools.

Let’s say you are in the same situation but aligning with dial indicators. The indicator needle is jumping back and forth between 35 and 42. Most likely, you will settle for the average midpoint of 38 or 39. You can do the same with lasers.

The first thing to do would be to switch over to one of the “manual” measure modes (like Multipoint mode) rather than the fully automatic measurement modes (like Continuous Sweep or Pass Mode.) In Multipoint, you can adjust the averaging (sampling time) for each reading and spend a little more time taking each point. A longer sampling time will allow the tool to take much more data at each measurement position and average the data together very accurately, unlike guessing as with the dials. It is also a good idea to take several positions (8 or more) around 360 degrees of rotation. While the minimum required is 5 points over 70 degrees of rotation, the more points and the more rotation you have, the better your results will be. Check your repeatability. If it’s not good, look at your Standard Deviation values. These should be very low. If they’re not, then perhaps your averaging still isn’t set high enough to overcome the surrounding vibration problems. If you can’t get repeatable numbers, spend a little more time taking readings. No one likes chasing their tail making fruitless or inaccurate corrections.

Live move can also run into some problems in high vibration scenarios. Make sure you adjust the averaging value for the Move Function to the same value with which you took successful readings. It may take longer for the results screen to update but will steady the move and greatly improve its accuracy.

The thing to keep in mind is that a good laser alignment system measures down to 1/25,000 of an inch. If the laser is moving, it will affect your readings. Just know how to overcome the problems when you run into them.

We recommend that you take a look at our Alignment Matters Repeatability Video Tutorial

by Tyler Wulterkens CRL

A lot of facilities assign condition monitoring intervals based upon arbitrary schedules such as 30, 90, 180 or 365 days. Often, this is due to a lack of understanding of how equipment fails, misunderstanding of how conditional tasks such as vibration analysis work, available labor, and lack of importance placed upon condition monitoring efforts. These arbitrary collection intervals can actually lead to failures that go undetected and a loss of value from the effort.

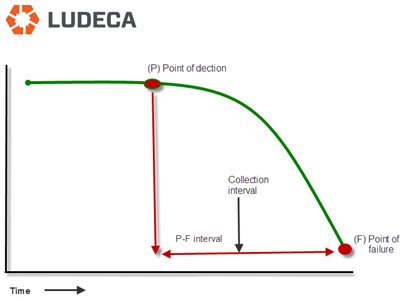

To appropriately determine monitoring intervals, a couple of things should be known. First, the point in time (P) that the potential failure becomes detectable must be known (detected with vibration monitoring, for instance.) Second, the time (F) at which the potential failure would degrade to a functional failure must be known. This difference in time (P-F Interval) is the window to take corrective action and avoid the negative consequences of the failure. This difference in time will determine how often conditional tasks such as vibration monitoring must be done to detect potential failures from such things as bearing issues, etc. Typically, the monitoring interval would be set to half of the P-F interval. This allows enough time for the technology to detect the problem and for corrective action to be taken. However, in certain circumstances, it may be necessary to collect data at shorter intervals than half of the P-F interval.

It is important not to assign monitoring intervals based upon gut feelings, arbitrary calendar intervals, and so forth. Let the equipment tell you how often monitoring must be completed. Not understanding the process above can lead to costly results!

by Trent Phillips CRL CMRP - Novelis

The following blog relates to those who field balance using a photo or laser tach and reflective tape.

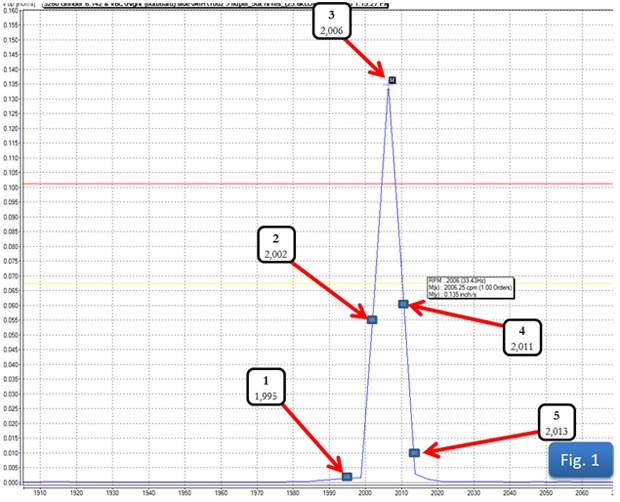

By far the most common pitfall to field balancing is a problematic tach signal. When one balances a rotor using one’s field balancing unit (VIBXPERT® II, VIBXPERT, or VIBSCANNER®) the equipment is recording the energy displayed at the frequency of the signal from the tachometer. To help visualize the importance of a clear tachometer signal that is exactly 1 pulse per revolution, look at figure 1.

What amplitude will your equipment record if the tach pulses:

1. 1,195 times per minute?

2. 2,002 times per minute?

3. 2,006 times per minute?

4. 2,011 times per minute?

5. 2,013 times per minute?

We often start a balance job by haphazardly placing our tach and tape. Because both the tach and tape are well-engineered, we may go on without a problem. But just a little attention to some of the common tach signal problems is usually all it takes to avoid having to restart a botched attempt at field balancing. What should be avoided when setting up a tachometer?

1. Don’t place your tach too close to the rotor. Most tachometers are used in the fieldwork sending some type of light out and bouncing it back, so they have a sending function and a receiving function. The wavelength of the light is such that not just any light will be accepted by the receiver, but only that wavelength of light sent out by the sending unit. So the receiver counts a pulse every time that wavelength of light appears (or disappears, depending on whether you are triggering by leading or trailing edge). The receiver is no smarter than that, we must supply the rest of the intelligence. When we put the receiver too close to the rotor, even a poor reflector may be able to bounce back enough of the light signal to create a pulse. The balancing technician should determine the distance from the rotor to set up their tach with the understanding that they want a good signal bounced back from their chosen reflector AND ONLY THEIR CHOSEN REFLECTOR! Most often, a 6-inch space is sufficient.

2. Don’t place your tach pointing perpendicular to the rotor. Earlier we stated that “both the tach and tape are well-engineered”. One thing most of us field balancers take for granted is the reflective tape. This tape is actually a well-engineered tool. Reflective tape is faceted in such a way that light can strike it at an acute angle, and still be reflected right back along the axis from which it came. This allows the tach to be staged at such an angle that light will strike the rotor, even a rotor that is itself a good reflector, and be reflected off and away from the receiver UNTIL the tape comes into the line of the light, and then with its special faceting, it will bounce the light back to the receiver. This gives one clean pulse every time the tape comes around, and only when the tape comes around.

3. Don’t use old reflective tape that may not be in proper working condition. Make sure the tape is clean and in good shape. Reflective tape works very well when it is clean and in like-new condition, but can get dirty or even deteriorate if conditions are right. Replacing a small piece of tape is most often very quick, easy, and cheap compared to extra balancing runs or possibly even worse.

4. Don’t use a tach with dirty lenses. Make sure the tach lenses are clean and in good shape. When your lens is dirty, it forces you to do things (in order to get a strong enough signal to go through the dirty lens) that aren’t conducive to a clean, clear, once per revolution pulse; like move the tach too close to the rotor, or place it at a 90° angle to the rotor.

Doing everything we have suggested here could take all of 5 minutes (if you work slowly) at the beginning of a field balance job, but it could save a lot!

by Mike Fitch CRL

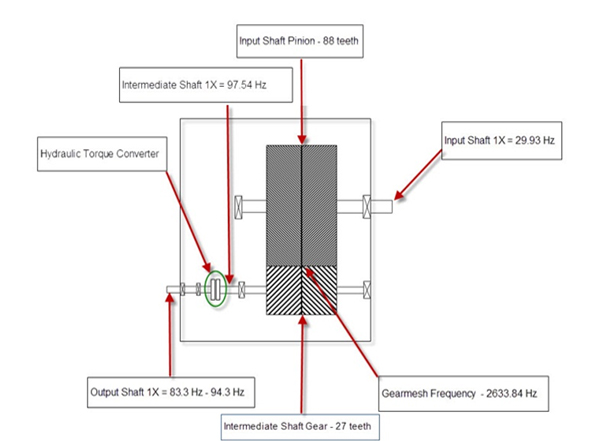

Recently, while assisting a customer in setting up a vibration database, the subject of creating the best trending template for a boiler feed water gearbox came up. This particular application requires trending templates to monitor a complex machine train consisting of four separate machines. For the purpose of this discussion, we’ll concentrate only on the gearbox in the machine train. The gearbox is a speed increaser. It is a little unusual in that a hydraulic torque converter allows the speed of the main boiler feedwater pump to be varied. This gearbox is designed with three individual shafts (an input shaft, intermediate shaft and output shaft), all enclosed within a single gearbox housing.

The speed of the input shaft is constant at 29.93 Hz (1796 rpm) and attached to this input shaft is a pinion gear with 88 teeth. The pinion gear runs in mesh with another gear mounted on the intermediate shaft with 27 teeth. This results in a gear mesh frequency of 2,633.84 Hz. We must determine the required frequency range (Fmax) by multiplying our calculated gear mesh frequency by 3.25 resulting in a Fmax of 8559.98 Hz. In the software, we can’t select 8559 Hz so we’ll need to select the next higher value, 10kHz.

The next step in the process is to determine the speed of the intermediate shaft by using the following formula:

Intermediate shaft speed = 29.93 Hz × 88 teeth = 2,633.84 Hz / 27 teeth = 97.54 Hz or 5,852.4 rpm.

We must now determine the required lines of resolution (LOR) since we have two fairly closely spaced running speeds. We have the intermediate shaft speed, running at a constant speed of 97.54 Hz and the output shaft speed which is variable.

When the boiler feedwater pump is operated at 100% the output shaft running speed of the gearbox is 94.33 Hz or 5660 rpm. There are only 3.21 Hz or 192.6 CPM between the two shaft speeds within the gearbox. Therefore, our lines of resolution setting will need to be high enough to provide separation while performing analysis. With a Fmax setting of 10kHz, we will need a minimum of 3200 lines of resolution to distinguish between the two shaft speeds. 10kHz Fmax / 3200 LOR = 3.125 Hz bin width, but to be on the safe side I would recommend selecting the next higher resolution setting (6400 LOR). This will provide a 1.56 Hz (96.3 CPM) resolution to easily see the two different shaft running speeds for accurate analysis.

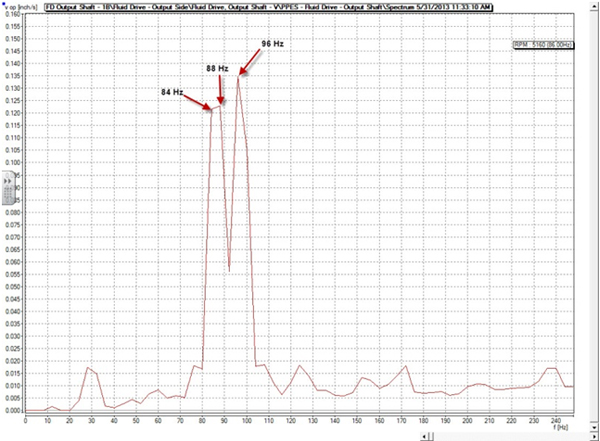

Below is an example of improper resolution for accurate analysis:

Improper resolution settings resulting in a flat top 1× for the output shaft speed. Proper resolution settings:

Correct resolution settings allowing clear distinction of the output shaft speed.

The lesson here is that proper vibration analysis requires understanding the machine design. Additionally, it is critical that the proper maximum frequency (Fmax) and lines of resolution (LOR) be determined. Improper Fmax settings will result in data being missed. Inadequate lines of resolution (LOR) can cause closely spaced peaks to merge together making it impossible to distinguish between them. These errors will result in poor vibration analysis results. Pay close attention to the details when setting up the equipment in your vibration database.

by Dave Leach CRL CMRT CMRP

Grease, excess paint, etc. can affect the quality of collected vibration data. The below 3 steps will ensure that the best possible data quality is always collected:

- Always carry a rag, scraper, brush, etc. to clean each measurement location before acquiring vibration data.

- Make sure that the measurement surface is flat and the sensor is not rocking during data collection.

- Hold the cable during data acquisition to prevent movement that may induce electrical noise and affect measurement quality.

Learn about the Triboelectric effect on vibration accelerometers

by Trent Phillips CRL CMRP - Novelis

Equipment is being built lighter and cheaper. This means that resonance has become more of a reliability problem with the equipment. Most engineers, CM analysts, mechanics, and managers are not aware of how resonance may be affecting their equipment. Resonance frequencies will excite any vibration occurring at or near the same frequency. This can include misalignment, unbalance, bearing faults, or other defect frequencies. This will cause your equipment to fail more quickly as well as other unwanted effects.

You should be aware of and document the resonance frequencies affecting your equipment. Many methods can be used to determine the resonance frequencies in your equipment and a good vibration analyzer will have the resources to help you do so. Methods such as an impact test (bump test), negative averaging, startup, coast down, etc. can be used to identify resonance frequencies. Additionally, the vibration analyst should look for signs of resonance-related issues when doing routine equipment analysis. For example, always look at the amplitude ratios between horizontal and vertical vibration measurements. Ratios of 3 to 1 or higher (horizontal versus vertical) are an indication of resonance issues in the equipment being monitored.

What should you do once a resonance problem is known and the unwanted reliability consequences understood? It is important to keep equipment operational speeds away from these critical frequencies by at least 20-30 percent. Actions can be taken to shift these critical frequencies and minimize and/or eliminate their negative effect on your equipment reliability. The primary methods are:

- Add Mass: Adding mass will lower the resonant frequency.

- Add Stiffness: Adding stiffness raises the resonant frequency.

- Damping: Dampens the vibration to keep it from becoming a destructive force

Make sure you understand the consequences that resonance has on your equipment. Not understanding and addressing equipment resonance will lead to unwanted and costly reliability issues.

by Trent Phillips

Equipment vibration levels and bearing life are directly correlated. Many studies have established this link. Increased vibration levels due to misalignment, unbalance, looseness and other factors will greatly reduce the life span of bearings and other critical components within your equipment. It is not the amount of vibration that affects bearing life, but the forces that cause this vibration. These dynamic forces are propagated into components like bearings, reducing their life span. Reducing vibration levels means that the forcing functions are reduced/eliminated and bearing life is improved as a result.

Reducing vibration levels in your equipment will decrease the maintenance efforts required to keep it running, improve uptime and save your company money. These savings can be used to help justify your condition monitoring and reliability efforts as well.

Eliminate vibration before it kills your equipment, production, and profits.

by Trent Phillips

PUMPS & SYSTEMS • September 2014

Revisiting the fundamentals of data examination, time and resolution can solve equipment issues before they happen.

Inexperienced vibration analysts encounter a common problem: They are often expected to learn too much, too fast. Instead of taking time to appropriately understand the basics, new analysts must often move directly to a busy schedule of collection and analysis without many apprenticeships. Training is almost always in a group setting, and instructors often move too quickly through the material. The facts are learned well enough for an analyst-level exam, but an in-depth understanding is often taken for granted.

Accurate vibration analysis requires complete clarity on foundational subjects. Real-world applications demand more of young analysts than what they can learn in group training. Facility operations depend on a whole picture of how their equipment moves and where energy is used—and lost.

Read my entire article The Basics of Spectral Resolution for Motor Vibration Analysis

by Mike Fitch CRL