Every person that performs vibration analysis develops his or her own analysis process. Suggested steps at a minimum should include:

- Open the spectrum (FFT) and locate the running speed peak and reset the reference speed to that speed. Since all induction motors vary in speed based on the load, this is necessary for accurate analysis, particularly at multiples of running speed.

- What are the dominant peaks?

- Are there any other peaks of interest?

- Where is the primary energy located?

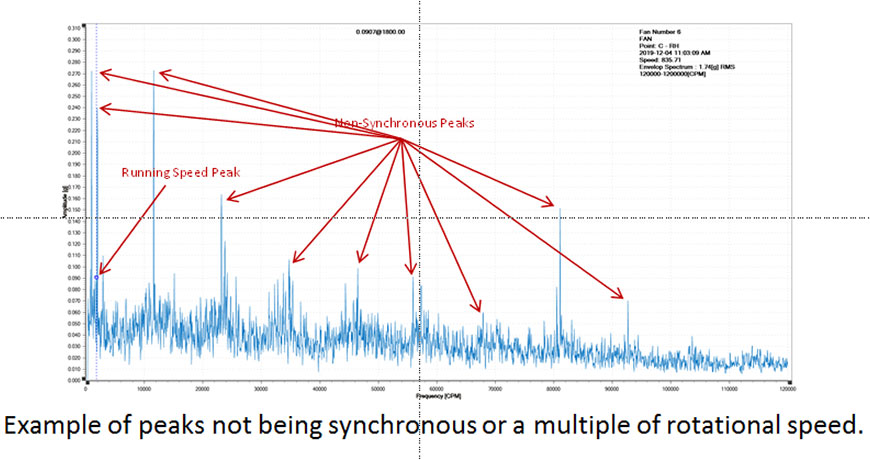

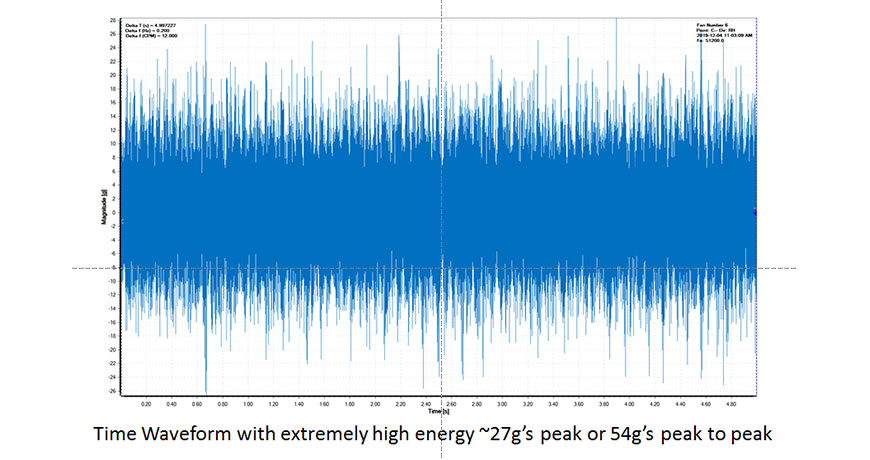

a. Is it sub-synchronous, synchronous, or non-synchronous? - Do the waveform patterns support the peaks in the spectrum (FFT)?

- Remember that defects follow patterns. Some defects happen at frequencies less than running speed (sub-synchronous) or at running speed or at multiples of running speed (synchronous), or at frequencies greater than running speed but not at whole integers (non-synchronous).

- Learn pattern recognition and don’t overlook the obvious.

- Generally, most equipment doesn’t have only one issue going on, learn to sort out the various problems and tackle the worst one or ones first.

Test Your Vibration IQ and see how much you know and maybe learn something along the way!

Related Blog: The Importance of Vibration Analysis

Filed under:

Maintenance Tips, Vibration Analysis by Gary James CRL