LUDECA is proud to announce that they are now an approved Reliability Leadership Institute (RLI) Mapped Services and Training (MSAT) Provider. As such LUDECA provides training and services aligned with the Reliabilityweb Uptime Elements for the Alignment/Balancing (A/B) domain under Asset Condition Management (ACM).

We are excited to be part of this program and thereby be able to better assist the Asset Condition Management community in their quest to eliminate machine defects in applying precision alignment and balancing techniques” says Ana Maria Delgado, CRL, Marketing Manager for LUDECA.

To support the MSAT program and better serve their customers with their maintenance and reliability needs, LUDECA recently certified 25 team members as Certified Reliability Leaders (CRL) and has embarked on a Reliability Journey to educate customers on the benefits of proactive precision alignment and balancing as a key step on the road to world-class reliability excellence

About LUDECA

LUDECA is a leading provider of Preventive, Predictive, and Corrective Maintenance Solutions including machinery laser alignment, vibration analysis, and balancing equipment as well as software, rentals, services and training. For more details, visit www.ludeca.com

About the Reliability Leadership Institute (RLI)

Reliability Leadership Institute (RLI) was established as a Community of Practice (CoP) in 2012 to improve how organizations deliver asset performance through the use of Uptime Elements, a reliability framework designed to enhance the triple bottom line of economic prosperity, environmental sustainability and social responsibility. Reliability Leadership Institute (RLI) has a reputation for creating knowledge that measurably improves reliability and asset performance strategies. More details are available at www.reliabilityleadership.com

About Mapped Services and Training (MSAT)

The Uptime® Elements™ framework is a system-based approach to embedding a reliability culture into an organization. As more asset managers are adopting the Uptime® Elements™ framework in support of ISO55001, there is a growing need for in-depth services and detailed “how-to” training related to the mastery of each element.

The Reliability Leadership Institute is introducing a Mapped Services and Training (MSAT) Providers program to assist potential clients in sourcing approved vendors on processes and technologies covered by the Uptime® Elements™ Framework.

by Ana Maria Delgado, CRL

LUDECA’s donation of its laser alignment system to Midlands Technical College prepares students for the real world.

Matthew Lester, an industrial training instructor for Midlands Technical College, was mindful of the good that would come from the donation of equipment from LUDECA. When Midlands Tech finally received the laser alignment systems and equipment, his dream of helping students prepare for their future jobs came true. Read the rest of the blog by Plant Services Magazine.

by Ana Maria Delgado, CRL

Ludeca opens up new opportunities for students by donating equipment to Midlands Technical College.

Our company which provides corrective solutions through laser alignment and vibration analysis donated some equipment to Midlands Technical College, a college located in South Carolina. We donated laser shaft alignment systems, shaft alignment simulators, laser pulley alignment tools to the college. These tools can help detect and correct machinery problems that affect machinery health and reliability.

Read the rest of the news article “Ludeca donates equipment to Midland Technical College” at Plant Services.

Watch Midlands Technical College’ MVPs of Advanced Manufacturing video which includes great testimonials from their mechanical and electrical technicians and features our ROTALIGN® ULTRA laser shaft alignment tool

by Ana Maria Delgado, CRL

LUDECA’s commitment to customer service goes far beyond the obvious, such as meticulous hands-on customer training, free tech support, free loaners while your equipment is being repaired, and all always having all accessories in stock for immediate delivery.

With LUDECA you are never in the dark.

An on-site propane-powered 150 KW fully automatic generator set keeps us instantly operational whenever power outages occur. The unit delivers sufficient electricity to seamlessly operate all our computer systems, air conditioning systems, lighting, climate-controlled laboratory, repair center, and our state-of-the-art Alignment and Condition Monitoring Training Center.

This means no interruptions in order processing, no delays in repair and calibration procedures, uninterrupted acclimatization of lasers and sensors for NIST-certified calibration, and uninterrupted training sessions for our students.

LUDECA—where the customer comes first!

Keep it running.

by Dieter Seidenthal

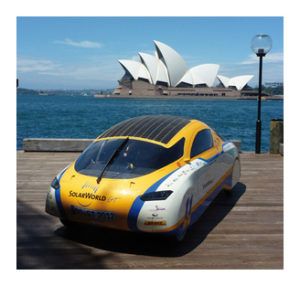

As announced back in April and as a result of PRUFTECHNIK Alignment Systems’ sponsorship of the SolarCar project, we are pleased to announce that they have made it to the finish line. The solar-powered vehicle “SolarWorld GT” has returned to Bochum, Germany after its journey around the world making honor of its motto “PRUFTECHNIK keeps the world rotating’”.

As announced back in April and as a result of PRUFTECHNIK Alignment Systems’ sponsorship of the SolarCar project, we are pleased to announce that they have made it to the finish line. The solar-powered vehicle “SolarWorld GT” has returned to Bochum, Germany after its journey around the world making honor of its motto “PRUFTECHNIK keeps the world rotating’”.

The SHAFTALIGN® tool donated to the University of Bochum was used to enable optimal alignment of the test bench for the wheel hub motors used in the SolarWorld GT. They were able to maximize the efficiency of the drive system for the solar vehicle, 29,710 km – on 177 days of driving – that was the reading on the odometer at the end of the trip around the world.

Once again, we salute PRUFTECHNIK, our principals, for supporting electromobility and demonstrating the achievements of their tools. Taking pride in the equipment they develop has definitely paid off.

by Yolanda Lopez

Shoreline Reliability, the northeast LUDECA Solutions Provider, was a proud supporter at the 44th Annual New York Citywide Graduating Apprentice Contest. In the contest the graduating Millwrights were asked to layout, assemble and align a bevel gear project along with blueprint reading and perform laser shaft alignment demonstrations using the ROTALIGN® ULTRA iS. All tasks were directly related to what the graduating apprentices will encounter in the field. The contest was held at the New York City District Council of Carpenters Labor Technical College, where the millwright courses have utilized the OPTALIGN® and ROTALIGN products dating back to the mid-1980s. The forward-thinking school also plans to incorporate the CENTRALIGN® ULTRA for bore alignment as well as introduce vibration analysis and balancing with the VIBXPERT® II.

The contestants had 7 hours to complete all tasks and were judged on accuracy and precision. This year’s Millwright winner was Michael Giorgi, followed runner-up Michael Daniels and 3rd place went to Mohammed Arif. Congratulations to all participants and we look forward to many more years of working together with the NYC District Council of Carpenters Labor Technical College.

by Ana Maria Delgado, CRL

As Published by BIC Magazine December 2012/January 2013 issue

LUDECA has unveiled a new logo, slogan and mission statement backed by the same fundamental values on which the company was built.

“Our new slogan — ‘Keep It Running’ — is indicative of what our condition monitoring solutions are committed to doing, which is keeping U.S. manufacturing running and productive. It is what we have been doing all these years, and it was time to put it in writing.” — Frank Seidenthal, president, LUDECA Inc.

What began in the 1950s as a company in Nicaragua has since expanded to the United States and outgrown its smaller stature. LUDECA Inc. branched out with U.S. operations in Miami in 1979 with only three employees selling a pre-programmed dial indicator system at a time when the Internet and computers were virtually nonexistent within the maintenance arena.

“Everywhere you turn now, the access to information is tremendous,” Seidenthal said. “Along with all of this technology, our product range has also expanded extensively to include not just shaft alignment but geometric tools, portable and online vibration analysis solutions, and balancing tools.”

To accommodate the growth during the last few years, the company moved to a state-of-the-art facility in Doral, Fla., and grew employment by an additional 15 percent in 2012 alone. Additionally, LUDECA now has field offices in several locations throughout the United States. In light of the growth, the team at LUDECA has unveiled a new logo, slogan, and mission statement backed by the same fundamental values on which the company was built.

“We wanted a look and feel that was fresh and modern to reflect our growth and core company focus,” Seidenthal explained. “Not only do we sell state-of-the-art cutting-edge products but we also improve our customers’ equipment reliability. We created a mission statement to emphasize this priority to both our employees and our customers that, at LUDECA, we maintain a high standard of ethics, service, and customer support by always striving to exceed customer expectations. The proof is in our growth and high rate of repeat business.”

The company’s new mission statement reads “LUDECA’s goal is to be the premier provider of reliability solutions and technologies to industry. Our years of experience and wealth of knowledge make it possible to offer the very best service and support to our customers. We are, and seek to remain, the leading suppliers of laser shaft alignment and geometric systems, laser sheave alignment tools, and vibration and condition monitoring systems to the industry. LUDECA’s commitment to our customers strengthens our reputation as the very best in our fields, thereby creating and maintaining long-term customer partnerships.”

“We view our employees as our greatest asset,” Seidenthal said. “And in line with taking care of our customers, we take very good care of our employees and invest heavily in our staff to ensure they are always up to the challenge. They are our front-line personnel, and it is extremely important they are able to fulfill the needs and requirements of our customers.”

“In turn, our customers are our No. 1 priority, and they understand we will take care of them. We want to make an emotional connection with our clients. It isn’t just the product purchase. We are here for anything they need after the purchase.”

by Ana Maria Delgado, CRL

We are proud to release a new version of our “Laser Align” mobile application. The app is available in the iTunes Store for both iPhone and iPad; as well as in Google Play for Android. The application now has an interactive Tolerance Table, where the user can input his own machine RPM and the app will kick back the respective Alignment Tolerances for both short flex and spacer type couplings. It also includes a Thermal Growth Calculator and now has a Soft Foot Assistant to help the user interpret soft foot values.

We are proud to release a new version of our “Laser Align” mobile application. The app is available in the iTunes Store for both iPhone and iPad; as well as in Google Play for Android. The application now has an interactive Tolerance Table, where the user can input his own machine RPM and the app will kick back the respective Alignment Tolerances for both short flex and spacer type couplings. It also includes a Thermal Growth Calculator and now has a Soft Foot Assistant to help the user interpret soft foot values.

The app is available everywhere for FREE. Download now.

by Adam Stredel CRL

MEDIA RELEASE

MEDIA RELEASE

The AHR Expo and its co-sponsors, ASHRAE and AHRI, have recognized our VIBCONNECT® RF wireless condition monitoring system with an HONORABLE MENTION in the BUILDING AUTOMATION Category of the 2013 AHR Expo Innovation Awards Competition. A panel of Industry Professionals, selected for their knowledge and expertise in HVACR, found our VIBCONNECT RF worthy of this recognition. Representing a broad cross-section of the HVACR marketplace, the winning entries were selected in 10 categories and represent the most innovative new products among the thousands that will be displayed at the show. A panel of judges made up of ASHRAE members evaluated the products submitted based on innovation, application, value to the user, and market impact.

Read the official AHR Expo Press Release.

Winners will be honored during the upcoming HVAC event, the 2013 AHR Expo, Dallas, TX – January 28-30. Register today for FREE exhibit hall pass.

by Ana Maria Delgado, CRL

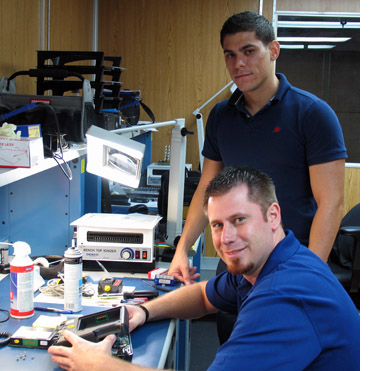

LUDECA is pleased to announce the addition of two new members to its Service Department, Damien Hamm and Luís Sánchez.

LUDECA is pleased to announce the addition of two new members to its Service Department, Damien Hamm and Luís Sánchez.

Damien Hamm served 9 years in the U.S. Army as an Automated Logistical Specialist/Infantryman. He is a graduate of the ITT Technical Institute with an A.S. in Computer & Electronics Engineering Technology. Damien is a member of the National Technical Honor Society.

Luís E. Sánchez is also a graduate of the ITT Technical Institute with an A.S. in Electrical Engineering Technology. Both Damien and Luís are currently pursuing their B.S. in Electrical Engineering Communications Technology.

Jens Heilemann, LUDECA Service Manager, states “We are pleased to have added Damien and Luís to our service team. With their expertise, we expect to further improve our top-tier customer service and maintain our signature quick turnaround time for all repairs and calibrations.”

by Ana Maria Delgado, CRL

LUDECA is pleased to announce the addition of two new members to its Laser Alignment Division, Kyle Daniels and Timothy Rogers.

Kyle Daniels is a graduate of The Ohio State University with a bachelor’s degree in aeronautical and astronautical engineering, and Brown University with a master’s degree in engineering and innovation management. His experience is in turbomachinery for aerospace and power generation, aerospace air management systems, and field service engineering for executive jets. Kyle also holds a patent on a new valve type and has received numerous honors and awards for his academic and professional work. Kyle states, “I am very pleased to join LUDECA, a high technology company with a strong culture of success and innovation, that offers a line of products critical to efficiency and reduced maintenance costs in industry.”

Timothy Rogers is a graduate of Florida International University with a bachelor’s degree in mechanical engineering. His experience is in the area of 3D mechanical computer-aided design and simulation software.

In their new roles, both Kyle and Timothy will support customers and regional distributors with new business development, applications and training related to machinery alignment and other industrial measurement tasks.

by Ana Maria Delgado, CRL

LUDECA, INC. introduces the VIBXPERT® II Balancer, the latest addition to the PRUEFTECHNIK family of portable measurement devices. The VIBXPERT II Balancer is a rugged yet lightweight device for field balancing of rotating machinery in one plane or two planes.

LUDECA, INC. introduces the VIBXPERT® II Balancer, the latest addition to the PRUEFTECHNIK family of portable measurement devices. The VIBXPERT II Balancer is a rugged yet lightweight device for field balancing of rotating machinery in one plane or two planes.

Unbalance is one of the most common causes of increased levels of vibration in plant equipment. The VIBXPERT II Balancer makes balancing easy with its intuitive and easy-to-use graphical interface, which leads the user through the balancing procedure step-by-step. Its large and bright color display facilitates the presentation and interpretation of the balancing data.

A variety of balancing methods can be selected to help the user balance equipment even in the most difficult situations. Built-in ISO tolerances alert the user when the equipment is within specification. In addition to its balancing capabilities, the VIBXPERT II Balancer features vibration analysis capabilities to support the diagnosis of unbalance and other types of equipment defects.

by Ana Maria Delgado, CRL

We are pleased to announce that PRUEFTECHNIK Alignment Systems —LUDECA’s principals— is an official sponsor of the SolarCar project conducted by the Bochum University of Applied Sciences in Germany.

Our shaft alignment system, SHAFTALIGN®, is the shining star of this project. PRUEFTECHNIK is supporting the SolarCar team with this system, which they are using to align the test rig for the development and optimization of the SolarWorld GT engines. Every tenth of a percent increase in the degree of efficiency is important to this project. Click here to learn more about this project.

We salute PRUEFTECHNIK for supporting alternative and renewable energy sources such as solar power.

by Yolanda Lopez

Our ROTALIGN® ULTRA Laser Alignment System is a winner in New Equipment Digest’s King Awards competition as one of the industry’s best new products of the year. It has won a Silver Award in the Facilities/Maintenance/Plant Operations category. ROTALIGN ULTRA is the world’s leading platform for precision measurement applications from shaft alignment to bore centerline alignment, flatness, and straightness measurement as well as continuous monitoring of positional change in machinery from thermal growth and other causes.

Our ROTALIGN® ULTRA Laser Alignment System is a winner in New Equipment Digest’s King Awards competition as one of the industry’s best new products of the year. It has won a Silver Award in the Facilities/Maintenance/Plant Operations category. ROTALIGN ULTRA is the world’s leading platform for precision measurement applications from shaft alignment to bore centerline alignment, flatness, and straightness measurement as well as continuous monitoring of positional change in machinery from thermal growth and other causes.

The King Awards competition, named after long time chief editor Bob King, was established to honor superior industrial product innovation. The print and digital readers of New Equipment Digest determine the winners by voting for the best products in 11 specific industrial categories. More than 6,000 votes were cast. We are proud to bestow these awards on significant and inventive products that enable all involved in manufacturing to do their jobs more efficiently and effectively. Congratulations on this achievement!

—John DiPaola, Vice President & Group Publisher, New Equipment Digest

Don’t miss the King Awards section in the April issue of New Equipment Digest magazine.

ROTALIGN ULTRA is manufactured by PRÜFTECHNIK Alignment Systems.

by Ana Maria Delgado, CRL

The Williamson Free School of Mechanical Trades’ Power Plant Technology Program recently obtained an OPTALIGN® tool, a high tech laser alignment system, from LUDECA, Inc, a company in Doral, FL, that specializes in predictive maintenance solutions. Don Meredith, of Precise Vibration and Alignment, Inc., spent a morning training power plant technology seniors and juniors in the use of the new system, which is used for turbine shaft alignment. The systems are important because good alignment helps turbines last longer.

John Beaudry, director of power plant technology, said, “We are really excited about this new laser alignment system. It will help us out tremendously in saving money and prolonging the lifespan of our turbines. Don’s training was the best introductory training session we have had yet. The students got a lot out of it. We are very excited to be developing a relationship with LUDECA, the company is known as the industry standard in laser alignment systems.”

Beaudry added that the system will be used in a shaft alignment course and will be an asset as more equipment is purchased for the Energy Island upgrade.

“This system will help us repair and maintain equipment in-house, such as the new turbines we will be purchasing. This will save us a lot of time and money and will provide good experience for our students.”

by Ana Maria Delgado, CRL

Our LEVALIGN® EXPERT Flatness and Leveling Measuring System with an Automatic Rotating Laser has been selected by the subscribers to Plant Engineering magazine as a winner in the 2011 Product of the Year Awards. The annual Product of the Year recognition, now in its 24th year, is the manufacturing and engineering industry standard for new product achievement.

Our LEVALIGN® EXPERT Flatness and Leveling Measuring System with an Automatic Rotating Laser has been selected by the subscribers to Plant Engineering magazine as a winner in the 2011 Product of the Year Awards. The annual Product of the Year recognition, now in its 24th year, is the manufacturing and engineering industry standard for new product achievement.

Winners are selected by a vote of qualified Plant Engineering subscribers – the engineers who buy, specify and use these products on a daily basis. They are the most qualified people you can find to understand how new products reduce energy costs, ensure safety and improve productivity on the manufacturing plant floor. That’s why the Plant Engineering Product of the Year award is so highly regarded in our industry. —Bob Vavra, Editor of Plant Engineering magazine

The Product of the Year awards will be presented at the 2012 Awards Dinner, presented by Plant Engineering and Control Engineering, to be held next March in Chicago, Illinois.

LEVALIGN EXPERT is manufactured by PRÜFTECHNIK Alignment Systems.

by Ana Maria Delgado, CRL

Back in July 2011, ArcelorMittal Point Lisas, Trinidad awarded TOSL’s Predictive Maintenance (PdM) Department with a one-year contract for Reliability and Condition Based Monitoring. It was the first time a process like that would be implemented at ArcelorMittal. The contract is being executed by our Senior PdM technician, Mark Dwarika, and PdM technicians, Samir Khan and Ramon Rabathaly.

TOSL’s PdM Department is currently facilitating ArcelorMittal with Reliability and Condition Monitoring Services, inclusive of vibration data collection and analysis, lube-oil sampling and analysis, as well as infrared thermographic inspection of the DR1, DR2, and DR3 plants. Over the short period since the commencement of the contract, the reliability of the facility has improved by approximately 8% —surpassing expectations.

Karth Arthur, Assistant Engineering Manager at ArcelorMittal quoted that:

“It gives me great pleasure to recommend TOSL Engineering Ltd to any firm. I have worked with TOSL from March 2010 to the present. During this time they have provided condition monitoring services to our five plants. These include Vibration Analysis, Thermographic Analysis, Electrical Signature Analysis (ESA), and Oil Analysis. The quality of work has been of the highest standard and their reports have been clear and concise. With these services, we have increased our availability by 15% and reliability by 8%. I recommend them with enthusiasm, and we will continue to utilize the services of TOSL Engineering Ltd”.

Early fault detection of rotating and static equipment components is a key factor in improving the mean time between failures (MTBF). The PdM technicians are now based at the ArcelorMittal as a fully incorporated faction of the facility. The interaction between the facility management, engineers, and TOSL personnel has improved the plant’s reliability to where a failure of components monitored and corrections made based on recommendations and consultation have decreased drastically. Monthly PowerPoint Presentations, departmental meetings, as well as equipment condition assessment reports, updating and emergency action plans on critical equipment are also major role that the technicians are either responsible for or play a role in.

Repairs on equipment are facilitated by ArcelorMittal’s respective maintenance departments, but it is also the PdM technicians’ responsibility to oversee and, if necessary, recommend changes to procedures in place. Overall the actions and recommendations collectively outline the basis of a functional Reliability and Condition Monitoring Program with improvements noted.

Congratulations to ArcelorMittal and TOSL Engineering Ltd., LUDECA‘s representative in Trinidad & Tobago, for their Reliability Achievements.

by Ana Maria Delgado, CRL

MEDIA RELEASE: New Product Revolutionizes Flatness Measurements

The LEVALIGN EXPERT Flatness and Leveling Measuring System with Automatic Rotating Laser has won 1st place in Pumps & Systems Product Innovation of the Year competition. The winners, finalists and honorable mentions were chosen by the magazine’s editorial advisory board.

The LEVALIGN EXPERT Flatness and Leveling Measuring System with Automatic Rotating Laser has won 1st place in Pumps & Systems Product Innovation of the Year competition. The winners, finalists and honorable mentions were chosen by the magazine’s editorial advisory board.

“This year’s winner is LUDECA, Inc. LUDECA’s LEVALIGN EXPERT is a tool that allows end users to determine the flatness/levelness of bases and frames. It helps avoid strain that can occur when a machine is bolted to a distorted surface. With a level surface, problems such as vibration and misalignment can be avoided, saving money on maintenance and repair and avoiding downtime.” —Pumps & Systems, December 2011.

Read official announcement including a LEVALIGN EXPERT field service engineer testimonial.

LEVALIGN EXPERT is manufactured by PRÜFTECHNIK Alignment Systems.

by Ana Maria Delgado, CRL

To ensure the highest quality service of your laser alignment tools, our Service Center recently underwent an in-depth factory evaluation audit which included extensive hands-on factory training for our service technicians. This also covered the EDDYTHERM® bearing heaters and the use of our new test and service diagnostics computer system with all our alignment systems.

The audit and training were conducted by Mr. Gerhard Kugler, Department Manager of Production and Service for Prueftechnik Alignment Systems, an ISO 9001 certified company, in collaboration with Jens Heilemann, Service Manager for LUDECA.

LUDECA is the only authorized repair and service facility for Pruftechnik AG products in the United States. Please note that any attempt to service any components by unauthorized entities will render all warranty coverage void.

Our service facility includes a NUPIC (Nuclear Procurement Issues Committee) approved calibration laboratory with NIST (National Institute of Science & Technology) certified calibration equipment and ESD (electrostatic discharge) protected facilities.

For more information, please contact our service department.

by Ana Maria Delgado, CRL

MEDIA RELEASE

MEDIA RELEASE

Awards continue for our VIBXPERT® II vibration analyzer. IMPO magazine readers voted in droves for the second annual IMPOvation product technology award. From a pool of 80 nominees, they picked our VIBXPERT II vibration analysis tool as their favorite Top 2!” Despite last year’s debilitating recession, the resilient industry has seen solutions providers continue to aggressively develop and produce truly unique and impressive products, services and software for the manufacturing sector —an inspiration that has reinforced the concept of IMPOvation.” “The VIBXPERT II rugged portable vibration analyzer, from Ludeca, combines a rapid processor with an energy-efficient color VGA display, which has 102,400 lines of resolution. All forms of machine vibration s, bearing conditions, process data, and visual inspection information can be collected and stored on the expandable compact flash card…” —IMPO magazine

by Ana Maria Delgado, CRL