The maintenance and reliability world is filled with key performance indicators (KPIs). Properly tracking KPIs can be challenging due to difficulties in obtaining accurate data and the time required to obtain them. The key is to pick KPIs that will help you identify and drive the behavior that you need to change right now. As advances are made, additional KPIs can be added which help identify and drive additional behavior changes and improvements.

It is very important to understand that KPIs can lead to false-positive indications and never actually result in value-added or sustainable improvements within your organization. You must understand and address the true root causes behind a deficient KPI and eliminate them.

For example, mean time to repair (MTTR) can be a very good indicator leading to great improvements.

Unfortunately, this indicator can also be harmful if misunderstood or given the wrong improvement focus. What if individuals decide to take deleterious shortcuts to quickly get a machine operational again? MTTR may seem to improve on that machine, but did overall asset health and reliability really improve, in a meaningful way that provides real value back to your organization? These shortcuts may actually lead to additional machinery failures and greater downtime.

MTTR could be an indication that maintenance staff requires training on how to properly repair the machine. Too short and perhaps unwanted shortcuts are being taken. Too long may indicate that excessive time is being wasted hunting for tools or spare parts due to a lack of proper planning and/or kitting. Is a detailed and efficient work plan available, to guide your maintenance staff incorrectly repairing the equipment? MTTR, if properly used and tracked can point you toward areas of substantial improvement.

Never forget to determine and address the root causes of equipment failure. Doing so may eliminate the need to work on the equipment in the first place. Prevention is always the best way to drive sustainable improvements in uptime and capacity.

Beware of driving improvements in KPIs for the wrong reasons. This can lead to a false sense of progress that never brings about real changes and advancements in reliability to your organization. Ensure that you understand the real variables driving the KPIs you have selected. Don’t let your chosen KPIs give you a false sense of improvement!

by Trent Phillips CRL CMRP - Novelis

How do you obtain the desired return on your assets? Availability, maintainability, and reliability are foundational elements required for a proper return on your equipment. Condition Monitoring is a tool that can help you build these elements and obtain the desired returns. Condition Monitoring can be completed while equipment is running to maximize uptime and help provide better overall reliability. Conditional changes can be identified before functional failures that result in downtime occur, preventing other unwanted consequences.

Unneeded work can be avoided (unnecessary PMs, failures, etc.), and better planning and improved scheduling achieved through CM.

Use Condition Monitoring as a means to build a solid foundation for your facility!

by Trent Phillips CRL CMRP - Novelis

Companies spend lots of money, time, and effort on systems to document what needs to be done, what should have been done, failures that occurred, etc. Unfortunately, these systems usually show and document the point of failure (F) and not the point of conception (P) for a problem. These are examples of downtime systems and are important for success.

Does your company invest in uptime systems and processes? What is an uptime system or process? These systems help your facility identify the point of conception (P) of a problem. This is very important because it means your facility has more time to mitigate a problem before it results in unwanted consequences (injury, downtime, increased costs, poor quality, less main profit, etc.)

Condition monitoring (CM), reliability efforts, proper planning, and scheduling, kitting, effective PMs, reliability-based engineering, etc., will reduce the amount of information that must be entered and tracked through the downtime systems that have been heavily invested in. The results can be extremely rewarding.

What uptime systems and processes does your facility utilize?

by Trent Phillips CRL CMRP - Novelis

March 2016 · Empowering Pumps Magazine

“Work smarter, not harder” is a statement we have all heard before, but who has the time to think about smarter ways to work when there is so much work to be done? Some maintenance professionals are so busy trying to keep their operation running smoothly that they often address equipment issues “reactively”. This might make maintenance teams feel more like “firemen” as they respond to in-the-moment needs. So how does a company become less “reactive” and more “proactive”?

Read the full article: Maximize Uptime with Asset Condition Management to better understand the key components of an Asset Condition Management (ACM) Program and how core technologies like Alignment, Balancing Vibration Analysis, and Ultrasound Testing can help you increase uptime.

by Dave Leach CRL CMRT CMRP

May 2016 · Plant Services Magazine

Like a lot of reliability engineers, Joe Anderson, former reliability manager at the J.M. Smucker Co., appreciated – in theory – that precise pulley alignment is critical to preventing vibration problems and ensuring successful operations.

My understanding was, ‘Yeah, we need to do it,’ ” Anderson says. “But you always have these excuses.”

When the Smucker’s plant at which Anderson worked launched a dedicated vibration monitoring and control program a year-and-a-half ago, though, Anderson quickly became a convert to making precision alignment a priority.

The plant purchased a vibration analyzer (VIBXPERT®) and laser alignment tool (the SheaveMaster® Greenline) from Ludeca to help aid in identifying machine defects that appeared to be linked to vibration caused by misalignment. Laser alignment allowed for correcting vertical angularity, horizontal angularity, and axial offset – the three types of misalignment – simultaneously. Whoever was using the laser alignment tool, then, could be sure that adjustments made to correct one alignment problem didn’t create an issue on another plane.

Read the entire article to learn how J.M. Smucker Co. made precision alignment a priority: Get your alignment in line: Don’t jiggle while you work

by Ana Maria Delgado, CRL

Guest post by Karl Hoffower – Condition Monitoring and Reliability Expert for Failure Prevention Associates

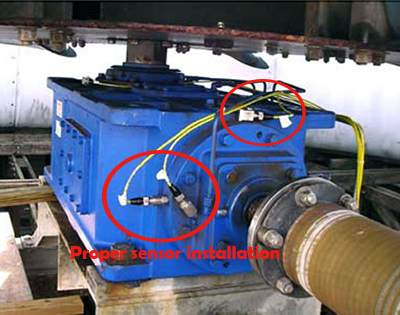

Location and placement of your sensors are crucially important when doing predictive vibration analysis.

1) Below is an example of proper sensor installation on a cooling tower gearbox. These two sensors are placed in different directions to follow both the gearbox vibration as well as indicate if the fan blades become unbalanced.

Read Vibration Sensors for Cooling Towers case study from CTC for details on proper sensor installation on cooling towers.

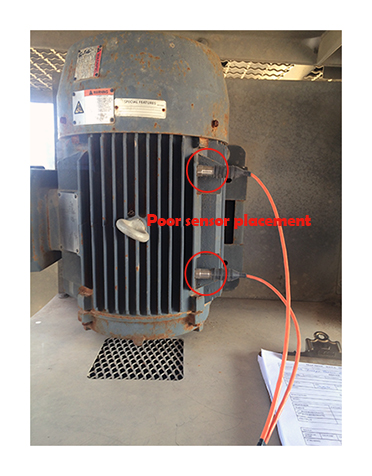

2) This example of poor sensor placement is on a vertical motor using a belt drive for a fin fan.

PROBLEM

- The vibration sensors pictured on the left are attached to one of the motor fins. Watching these sensors, one could visually see the fin and sensors oscillating as if on a trampoline.

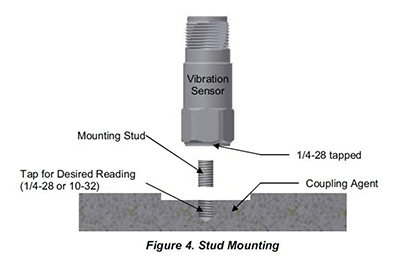

SOLUTION

- The choices are to face, drill & tap (see figure #4 below).

- The other option would be to epoxy a mounting pad to the bearing housings. Then screw the sensor into the mounting pad.

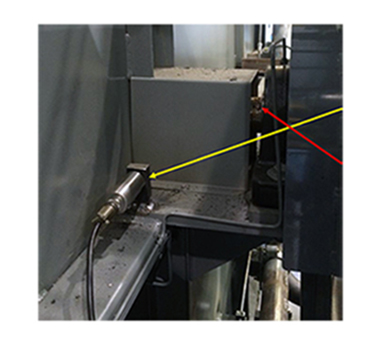

3) Another example of poor sensor placement on a 4-20mA shutdown switch on a gas recipient compressor at a facility in Texas.

PROBLEM

- The vibration sensor (yellow arrow) is a 4-20mA accelerometer used for asset protection in an automatic shutdown setting. It is monitoring the overall vibration levels emanating from the bearings and shaft (red arrow).

SOLUTION

- The better choice would be to use a mounting pad attached to the pillow block bearing.

by Yolanda Lopez

Does your maintenance staff have to wait on parts, wait for the equipment to be available, search for tools to do their job, work lots of overtime, travel long distances to the job, etc? Most maintenance staff work in pairs. This means that when you see one of your maintenance staff struggling to do his job, then his counterpart is struggling as well. What is the result? You may have a hidden cost (twice the labor) that you did not realize!

What can you do to avoid this? Make sure that your work is correctly planned. Job plans should be created, and be accurate and available. The required parts should be staged once the work is planned. Machine drawings, special tools, permits, etc., required to complete the maintenance activity should be identified in the job plan and be available as part of the job kit. Once all of this is done the work should be scheduled. These steps will help your maintenance staff focus on work and not on searching for the resources they need to complete their assigned maintenance tasks. You will save money and have more reliable equipment.

by Trent Phillips CRL CMRP - Novelis

Did you know that equipment PMs (Preventive Maintenance) tend to become more expensive over time? Why does this happen? For example, additional maintenance steps tend to be added to a PM as time passes. The machine configuration (design installation) changes and the PMs are never updated to reflect these modifications. Some PMs are not written correctly in the first place. All of this means that unnecessary maintenance is performed on your machines costing a lot of resources and money for a very long time. These are just some of the reasons PMs can be costly.

RCM and FMEA functions usually cost more money upfront and tend to be avoided as a result. However, these functions can clearly identify what maintenance actions should be performed on equipment and guide you to steps that will avoid maintenance issues. Condition Monitoring is another tool that works directly with RCM and FMEA functions to reduce PM activities and drive better equipment performance and reliability. These activities may cost more upfront versus a PM but will be much more cost-effective in the long run.

by Trent Phillips CRL CMRP - Novelis

Can a Reliability Engineer or Reliability Manager make a facility or organization reliable? This is a very important question that may be worth discussing within your organization to ensure proper expectations and success.

A more practical definition of reliability may be:

Equipment performs the way you want it to when you want it to”.

Reliability is very easy to define, stuff but achievement of this simple goal is complex and unfortunately unattainable for many organizations. Reliability requires a holistic approach that involves the complex interaction of Maintenance, see Operations, Supply Chain, Engineering, Procurement, Management, Process, and Vendors. Consistency, focus, and strategic implementation directly correlate to the success of any effort and this is true for your reliability efforts. Therefore, a consistent and strategic top-down focus is required from management and throughout each of these groups. Organizational misalignment leads to competing groups and will make sustainable reliability within your organization extremely difficult, and maybe even impossible to achieve.

Reliability Engineers and Managers can support reliability through leadership, training, tools, etc. However, the answer to the question is that everyone within your organization is responsible for reliability. It is critical that everyone within an organization understands this and that reliability is made a goal for each of these groups with defined metrics to track understanding and achievement.

So, who owns equipment reliability in your plant? The answer is Everyone!

by Trent Phillips CRL CMRP - Novelis

Most companies focus on repairing equipment after some functional failure has occurred and getting the equipment operational again. Is that the primary focus of your facility? Different studies have been completed by different organizations, which, while the percentages are different, all point to some very consistent and vital information. Design (engineering), installation (contractors, internal resources) and operation of the equipment all introduce equipment defects and drive reliability in your facility. Maintenance cannot overcome poor design, installation, and operation. Your maintenance staff can only deal with (repair) the consequences.

Your reliability efforts should be focused on preventing the introduction of defects in your equipment. This will help ensure equipment reliability leading to lower maintenance costs, increased capacity, and other positive results. Ensure that your equipment is designed, installed, and operated with reliability in mind. Make sure that you focus on the prevention and elimination of equipment defects as well.

by Trent Phillips CRL CMRP - Novelis

Maintenance and reliability professionals track many key performance indicators (KPI’s) to measure the success of their efforts. These indicators can be overwhelming but are necessary to confirm the proper direction and achievement of desired results.

It is important that your CMMS (computerized maintenance management system) has the ability to categorize work orders. Condition monitoring work orders should be categorized by main types and by sub-types (vibration, lubrication, thermography, ultrasonic, electrical, etc.) upon creation within the CMMS.

Your CM and Reliability team should actively track condition monitoring work orders by total created, their type (vibration, lubrication, etc.), status (in process, scheduled, completed, etc.), the average length of time to completion, rejection results, and so on.

These indicators will allow you to ensure that a healthy amount of CM work is available and that this work is given priority, being properly planned, scheduled, and executed. It does no good to detect and report a conditional change in equipment only to have it ignored, not properly repaired, and then result in a functional failure.

Additionally, technology alarm status can be compared to open corrective work orders in your CMMS. For example, a corrective work order should exist addressing each severe alarm condition (red) reported by a CM technology. If a corresponding work order has not been created, then you should ask “Why”? Is it due to a bad technology alarm? Did the CM analyst miss something or fail to report the condition or repair? Or did the planner or scheduler simply overlook or ignore it?

Monitoring these indicators can help ensure that your CM program is providing continual results that will move your reliability efforts forward.

What indicators do you track to determine success with condition monitoring efforts within your company?

by Trent Phillips CRL CMRP - Novelis

WIP is an acronym for “Work In Progress”. An example of WIP is when the widget must progress through different production processes that change fit form or function before reaching a stage of final completion and readiness for shipment to the end-user. Work management is required to ensure the widget moves through these stages at the proper time and under the correct conditions. Most production facilities have some type of WIP that is followed.

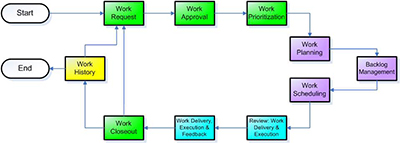

Maintenance activities must follow a WIP process to ensure success as well. As the graphic below illustrates maintenance work should start out as a maintenance request and progress through the critical stages shown below before competition. Each stage must be closely monitored to ensure that bottlenecks do not exist or stages are bypassed as the work is started and executed.

The goal is to ensure that the Right Work is done at the Right Time and in the Right Way. Feedback and work history make the final steps in the execution process to help ensure any improvements are known and implemented.

Do you WIP your maintenance process to ensure proper execution of work?

by Trent Phillips CRL CMRP - Novelis

Management and co-workers do not always understand why Condition Monitoring (CM) Analysts spend so much time in an office looking at a computer screen. What are they doing? What does that have to do with condition monitoring activities, equipment repairs, and reliability efforts? Why are they not in the field collecting data?

Why are they not working on equipment maintenance? Unfortunately, these misconceptions often result in a perception that CM Analysts are not doing their job and they are pulled back into routine maintenance activities or assigned other work tasks.

The reality is that four critical steps must be consistently completed by a CM Analyst for the program to be successful. First, valid data must be collected with the CM technology at proper measurement intervals. Second, the collected data must be properly analyzed. Third, the findings must be promptly reported in a meaningful way to those responsible for planning, scheduling, and completing the CM results. Fourth, the database(s), measurement methods, and equipment information must be constantly updated. Additionally, routine research is required to ensure that proper measurement and analytical techniques are being applied, needed information is available, etc.

Successful completion of the critical steps outlined above requires time in an office environment using a computer. Not allowing your analyst(s) this necessary time will ensure failure and result in needless reliability issues. An old rule of thumb is that for every hour a CM analyst spends in the field it will require an hour in the office processing that data, reporting the findings, etc., as explained above. The time in the office can vary depending upon how well the CM database is set up with proper alarms and measurement criteria. In addition, the analysis software, CMMS software, and other resources can be a critical factor in determining how much office time is required.

The point is that an analyst requires office time to properly process, report, and maintain his CM efforts.

Otherwise, the CM program is certain to fail. Provide time for the analyst(s) to do the job being asked of them or don’t be surprised when these efforts fail.

by Trent Phillips CRL CMRP - Novelis

As Published by BIC Magazine December 2015 issue

A world-class reliability program is not achieved overnight, yet you must start somewhere. Your first step is to vest your entire human capital in its success. Reliability is a culture, not a goal, and it flows from the top down.

Therefore, executive sponsorship with integrity and enforcement is a must. Obtain buy-in to the culture of reliability from everybody in your organization, or the effort is doomed to fail. Start with this realization, and your reliability effort will ultimately succeed, and you and your stakeholders will reap its rewards.

The reliability workflow must be well organized and underpinned by a Computerized Maintenance Management System (CMMS). Let’s look at how it works in a world-class program.

Ultrasound analysis detects a bearing fault in a critical motor early in the P-F curve. The analyst enters this data in the CMMS and trends it. The analyst decides to request a work order with recommendations. This is Stage 1 in the work order process.

The work order is now reviewed by both maintenance and operations, thereby ensuring buy-in from operations as well. This is Stage 2. This review process ensures only truly needed or valuable work is approved. Also, older open work orders can be combined with this one to further streamline planned activity on the asset. For instance, an earlier work order was created to align the machine, but the work was never carried out, resulting in the bearing damage the ultrasound analyst has now detected. The review process would catch the older open order and add it to the present order. This would prevent the millwright from going out to align the machine tomorrow only to have a repair technician go out the following week and repair the motor but do no alignment on it. This review process tries to eliminate inefficiency, duplication, and detrimental work sequences.

Stage 3 assigns the work order to the maintenance planner for action. Only approved and truly necessary work enters the planner’s backlog. The planner ensures work is properly prioritized. Two things are needed: The criticality ranking of the asset (ascertained from systems’ criticality analysis) and its operational criticality. Both of these factors can be multiplied together to create a more accurate prioritization of the workflow. The planner creates a new work plan if needed and should consult with maintenance supervisors and technicians; valuable insights may be gained into what parts, tools, and equipment should be specified in the work plan. Next, the planner orders the maintenance, repair and operating materials (MRO) spares, and tooling required to complete the job and verifies the parts are available and kitted (best practice). The planner should not concern himself with scheduling.

Now on to Stage 4: assignment to the scheduler. The scheduler allocates the HR and necessary time to accomplish the task, with a cushion for unforeseen complications. He too should consult with the maintenance supervisor and technicians to obtain cooperation and buy-in to the schedule. Coordination with operations is crucial. Operations “owns” the equipment and must sign off on the schedule to bring the asset down.

Stage 5 assigns the order to the appropriate maintenance and electrical supervisors, who in turn assign specific tasks in the work plan to their respective repair technicians, electricians, and millwrights, and verify MRO spares has delivered the parts kit to the proper location.

Now the work order enters Stage 6: the work execution phase. Once the technicians have completed the work, they report to their supervisors, who return the asset to active duty status in the system. Operations is notified the asset is ready for service, and MRO spares is notified of any unused parts and supplies that should be returned and reintegrated into the MRO spares inventory. Technicians and supervisors should feed their observations and data into the CMMS system.

Stage 7 sees the ultrasound analyst performing follow-up data collection on the asset to ensure all is well. The work now goes back to the planner to be formally closed. This ensures all important data has been accumulated and distributed within the system, enabling key performance indicators to be updated.

As good data accumulates, reliability engineering will use it to improve the entire reliability and maintenance process, discover frequent failure patterns, identify training needs, drive out defects, streamline production and help to improve the design process. As the plant becomes more efficient and productive, greater resources can be allocated to defect elimination and strengthening condition-based maintenance technologies, further impelling the transition to a proactive, reliability-centered culture. Reliability is a never-ending journey of continuous improvement.

by Alan Luedeking CRL CMRP

In today’s world, video platform is the way to accomplish effective visual knowledge and a learning mechanism in many organizations. With the use of video, one not only is able to promote products and services but one can also strengthen a culture and demonstrate how-to scenarios easily and quickly.

LUDECA believes in communicating visually to help customers educate and train their personnel on precision skills. For this reason, we are pleased to announce the release of our new microsite www.LudecaVideos.com, which features a Shaft Alignment Know-How series plus a Know-How series for Vibration Analysis and Balancing. The video site features basic terminology, fundamental concepts, advanced measurements as well as product demonstrations. The videos are indexed by category but also searchable by keyword.

We felt there was a need to go back to basics and help educate on precision skills and related technology to improve asset reliability. Following the Uptime Elements™ holistic approach to reliability, alignment and balancing are key components of your asset condition management (ACM) program. We are happy to offer these videos to our customers for their personnel to access and for use in their training programs. We hope this content assists them and others in either improving their reliability program or in getting one started and leads to world-class reliability programs,” —Frank Seidenthal, president of LUDECA.

We encourage you to visit www.LudecaVideos.com and see for yourself the value behind each video.

by Yolanda Lopez

Have you ever considered what your company’s definition of “maintenance” maybe?

Unfortunately, within many organizations “maintenance” is simply synonymous with “fix-it”. Maintenance is derived from the word “maintain” and that concept is critical for equipment reliability. Basically, your goal should be to maintain your equipment to some standard and functional ability. When equipment is allowed to reach a point of breakdown, then we have actually failed to maintain it.

How do we maintain our equipment to standards for performance, safety, quality, etc.? Here are four examples:

- First is design.

- Second: proper installation.

- Third: good operation – Improper operations can result in breakdowns and the inability of a machine to meet the defined standards.

- Fourth: precision maintenance skills, condition monitoring, planning & scheduling, and execution of the foregoing are required to maintain equipment and ensure it can meet functional requirements upon demand.

Always remember your maintenance department cannot overcome poor design, improper installation, incorrect operation of the equipment, and improper maintenance execution (poor craft skills, bad planning and scheduling, and so on). These things will result in repeated repairs (“fix-it”) and extra costs to meet the desired standards (operation, safety, quality, etc.) Properly maintaining equipment requires the involvement of many individuals and groups within your company.

Perhaps some discussion about the definition of “maintenance” may create opportunities for improvement within your company.

Visit our Knowledge Center for resources and tools to help you succeed when implementing and using our maintenance technologies! Watch our video tutorials, download infographics, plus explore other helpful information to reduce equipment failures and downtime.

by Trent Phillips CRL CMRP - Novelis

Have you ever been asked “How much longer will it run” or “Can we make our production schedule” or other ‘crystal ball’ type questions? These types of questions can be very difficult or virtually impossible to answer. They often place a reliability professional in a difficult position.

Some future indicators are (or should be) available to the organization that will help you answer the above questions when asked. Four of those indicators are:

- Preventive Maintenance (PM) Completion Rate

Low PM completion rates directly correlate to increased future equipment maintenance work. High PM completion rates mean that needed equipment maintenance is being completed and future maintenance issues will be avoided. - Ready to Work Backlog

This is an indicator of preparedness and efficiency to complete maintenance work. - Outage Schedule Compliance

This is a very important metric to track and is an indicator of future maintenance work. A lack of adherence to outage schedules creates deferred equipment maintenance. This results in increased risks and the likelihood that equipment performance will decrease at a future time, leading to lower capacity, increased downtime, and greater expenses. - Equipment Asset Health Reporting

Proper utilization of condition monitoring technologies like vibration analysis, IR thermography, lubrication analysis, ultrasound, and others are a proactive strategy to ensure that hidden failures become known and corrected before they result in equipment downtime or other unwanted consequences. Tracking these indicators together can provide insights into future asset health. A lot of “red” assets from these technologies will result in future unwanted equipment maintenance and unwanted downtime if corrective action is not taken. Additionally, this can be used to help prioritize equipment maintenance efforts if a good critical equipment ranking system is in place.

by Trent Phillips CRL CMRP - Novelis

Everyone within your organization should be passionate about improving and maintaining equipment reliability.

However, some groups have more or less to gain from that.

Unfortunately, skipping or moving planned work outages, rushing equipment repairs, not allowing proper maintenance activities to occur, and other disruptions are commonplace within many organizations. These are often influenced or controlled by the Operations Department.

The Operations Department within your organization should be extremely passionate and focused on ensuring that proper maintenance and reliability efforts are implemented and maintained. Why? This group has a tremendous amount to lose or gain from asset performance. This group should be an active part of all reliability efforts. The Operations Department should insist on activities like:

- Preventive Maintenance (PM) Optimization

- PM Compliance

- Precision Maintenance

- Root Cause Failure Analysis (RCA)

- Proper Planning and Scheduling (PS)

- Critical Spares Analysis

- Operator Care Activities

You must be a reliability evangelist and constantly provide education and awareness to help the Operations Department and others understand what they have to gain by promoting and insisting on reliability practices. This will help you lead your organization to improved and sustainable equipment reliability.

by Trent Phillips CRL CMRP - Novelis

Guest post by Fred Schenkelberg, Reliability Expert for FMS Reliability

A natural question to ask when something fails is “Why did it fail”?

The answer is not always obvious or easy to sort out. Some failures result from design errors, others are related to supply chain and assembly issues, and yet others occur because of seemingly random events (accidents, lightning strikes, etc.). As a reliability engineer, my concern is not simply accounting for end-of-life wear out; it is about meeting the operation’s reliability expectations. From design to failure analysis, by considering the range of possible sources I can identify and attend to the root causes that matter.

Consider a circuit board that has a small burn mark where a component exploded off the board. The customer failed to spot the missing part but noticed that certain features were no longer available. The box went dark and no longer powered up. It was dead, so the customer returned it. That is the failure mode – the loss of a feature or function. This is what the customer notices.

The engineer then has to investigate the root cause and identify the failure mechanism.

Failure Mechanisms and Root Cause

Failure mechanisms are the material or software code faults that lead to failure. They include thin insulation leading to dialectic breakdown, contamination leading to corrosion, or faulty code leading to an over-voltage command. Becoming aware of a product failure and starting to determine why it failed is an exploratory process.

The clues to when the failure occurs may help frame the initial investigation.

To answer the “Why did it fail?” question in a useful manner we need to determine the sequence of events that led to the failure. Root cause analysis is a process to determine this chain of events. The cause may be faulty material or assembly, damage, or design error. It may also include poor decisions and human error. Generally, we look for the physical or chemical reason for the failure. However, we should also explore the design, assembly, supply chain, and customer-related processes to ascertain where an error or weakness in the process could have contributed to the failure.

The idea behind seeking out root causes and determining failure mechanisms is to mitigate issues with problematic elements of the product whose failure would lead to product failure.

Types of Failures and Timing

Products fail for many reasons via many mechanisms. Most products have literally hundreds of ways in which they can fail. It is really a race between different mechanisms all vying to cause the failure. Eventually, everything will fail.

One of the first steps in sorting out the specific cause is determining when the product failed. How old was the product when it failed? Early life (e.g., when a product is just bought and installed) failures tend to cause more customer anguish than a product that has provided a long life of useful service. In general, we often talk about three periods of failure:

• early life failures

• random failures

• wear-out failures

The three periods are often depicted with a curve-shaped like a bathtub. The bathtub curve is the aggregate of many potential failures. Some tend to occur early, whereas some occur later. Each individual product has many possible ways in which it can fail and the most likely failure mechanisms may change over time as the product use and conditions change. Keep in mind that the curve is a fiction to explain a hypothetical profile of possibilities of failure over time for a single item.

Each period of failure also suggests a set of possible causes. Although this set is not always accurate, it provides a good starting place when looking for the root cause.

by Yolanda Lopez

Guest post by Fred Schenkelberg, Reliability Expert for FMS Reliability

In a previous posting (”Five Steps to Building a Better Reliability Culture”, posted on 10/06/2015), I discussed equipment reliability, reliability engineering, and reliability management. But this Holy Trinity of reliability does not operate in a vacuum. Creating a sustainable reliability program within an organization requires an understanding of its culture as well as its structure.

Every organization or product is different. The technology, expectations, and environments are all different. Consider two organizations, each of which has a reliability professional well versed in a wide range of reliability tools and processes. One of these professionals provides coaching and mentoring across the organization and encourages every member of the team to learn and use the appropriate tools to make decisions; the other performs nearly all the reliability work independently without support or consultation with team members. It is easy to see that the first organization’s team, being empowered to make decisions about reliability, will be better equipped to meet its reliability goals.

Thus differences in the basic culture of an organization can lead to vastly different approaches to how reliability is incorporated into its operations. An organization that incorporates reliability into its internal processes starting from the design phase will inevitably experience fewer failures and make more efficient use of its design team and suppliers. How the reliability professional functions within an organization have a strong impact on its culture.

The organizational structure of an organization is also intertwined with its culture. There is no single organizational structure that leads to improved product reliability performance over any other structure. Both centrally and distributed reliability teams have successfully created reliable systems. Even the presence or absence of reliability professionals on staff is not an indicator of reliability performance.

Top-performing organizations use a common product reliability language and possess a culture that encourages and enables individuals to make informed decisions related to reliability. Individuals across the organization know their role to both use and share information essential to making decisions. There is an overriding context for reliability decisions that balances the need to meet customer expectations for reliability along with other criteria. Alignment exists among the organization’s mission, plans, priorities, and behaviors related to reliability.

Equipment reliability is not the only element that benefits from a proactive culture. Whether top-performing organizations enjoy a proactive culture that naturally includes reliability activities to make decisions or evolved while improving product reliability to become a proactive organization with collateral benefits for other areas of running the business remains unclear. The latter is more likely since it takes leadership to build and maintain a proactive organization, although some organizations focus on building a proactive reliability program and develop the benefits later in other functions of the business.

Moving the organizational block around the organizational chart may have some value, although it is not directly related to improving reliability. It entails a more fundamental change than developing the reporting structures to transition from a reactive to proactive reliability program.

Once a group of people gets settled into a routine way of accomplishing something, it is not a simple matter to change the process. Doing so requires overcoming organizational inertia. For reliability professionals to implement reliability improvements, overcoming this inertia entails working closely with key influencers, making the current reality visible and accessible, and celebrating successes. Although every organization is different and every situation warrants its own approach, these three paths to overcoming inertia may facilitate the implementation of any proposed changes.

Overcoming organization inertia is one crucial aspect of changing a reliability culture. Some organizations tend to react to reliability issues. Prototype testing and downing events continue to surprise the team. The worst organizations fall into a cycle of always finding someone to blame. Better organizations set out to work to understand the problem and quickly resolve the issue. Some have better ‘fire departments’ than others. However, responding more quickly is often not the best way to deal with reliability. The very best organizations prevent issues from creating surprises in the first place.

Understanding the reliability culture is the first step to changing it.

by Yolanda Lopez