TransAlta from Alberta, Canada won Uptime Magazine’s Best Vibration Analysis Program. Their Vibration Journey started when due to distance and the high costs of using a contractor, they moved away from outsourcing their vibration analysis services to a full-time in-house vibration analyst.

During the implementation and mentoring period, and in spite of the business justification, they faced challenges like skepticism from the maintenance department and having to continually justify their existence. Buying and implementing new technology was easy but changing the culture was difficult. Some of it was overcome with their ability to be 100% correct on the calls they made for failures although at the beginning they did not catch all the failures. 10 years after their vibration program started, there are no more skeptics.

An important element of their success was the implementation of a training and certification program with a budget that allowed for 2 weeks of training per year per analyst. They also required that personnel take CMVA Level 1 (Canadian Machinery Vibration Association) or equivalent followed by Level 2 after 18 months and Level 3 within four years on the job.

Aside from bringing Vibration Analysis in-house, they also implemented other in-house programs such as Laser Alignment, Balancing, Ultrasound, Lubrication, and Thermography.

What did they accomplish? Savings of US$ 4,000,000 per year for their company over 1,600 pieces of equipment at 3 separate plants.

When first asked about their program, Mark Kumar told Terry O’Hanlon, publisher of Uptime Magazine, that their Best Asset was their vibration database (history) which allowed them to diagnose failures but now in retrospect, he stated that their Best Asset was the Backing of Company Management which supported their initiative for an in-house vibration program.

Congratulations to Harvey Henkel, Mark Kumar, and their team for this award and a job well done.

by Ana Maria Delgado, CRL

Domtar Espanola from Ontario, Canada won Uptime Magazine’s Best Asset Health Management Program. Their goal was “Go from Reactive Maintenance to Proactive”.

To achieve this goal, they put together a plan including several proactive actions and PdM technologies integrated with an Asset Performance Management Software which allows them to closely monitor equipment health. Kim Hunt shared some of their plan elements:

- Implement a precision lubrication program and oil analysis

- Skills training: Value your staff and empower them with training. From formal training to just watching Reliabilityweb Webinars together and afterward eating cookies and holding discussions —great for team building!

- Size your equipment properly

- Use laser alignment and balancing for precise machine rebuilds and installs

- Precise operator care

- Maintain excellence in housekeeping

- Equipment health monitoring. Use predictive tools, primarily vibration analysis to baseline your equipment.

- Root cause analysis and problem elimination

- Plan and schedule your maintenance activities with effective standard operating procedures

- Continuous improvement – you are never done!

What did they accomplish?

- 21% reduction in maintenance costs

- 30% increase in production efficiencies

- Increase MTBF (Mean Time Between Failure)

- A total average savings of US$450,000 per year without actual/potential product loss.

Congratulations to Kim Hunt and her team for this award and a job well done.

by Ana Maria Delgado, CRL

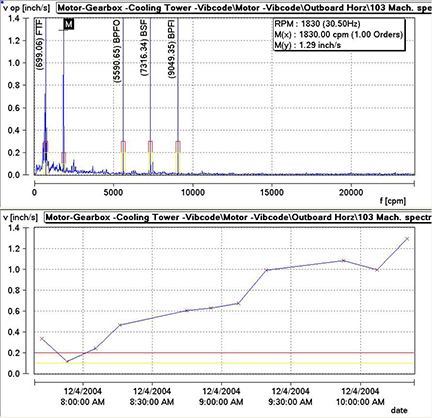

Knowing the exact bearing information for your equipment can make bearing defect analysis much easier.

However, it may not always be possible to acquire the bearing information for your equipment. This can make it difficult to determine the bearing fault frequencies for correct analysis.

It is possible to remember easy formulas to calculate the approximate bearing fault frequencies for rolling element bearings. The following formulas are easy to remember and can help you when the bearing information is not known:

FTF = 0.43 × RPM

BPFO = 0.43 × N × RPM

BPFI = 0.57 × N × RPM

Where:

FTF = Fundamental Train Frequency

RPM = Revolutions per minute

BPFO = Bearing Pass Frequency Outer Race

N = The number of rollers

BPFI = Bearing Pass Frequency Inner Race

The values derived from these formulas should be within 10% – 15% percent of the actual bearing fault frequencies.

Other formulas are available that will more accurately estimate bearing fault frequencies than the ones listed above. LUDECA will be happy to provide those to you upon request.

by Trent Phillips

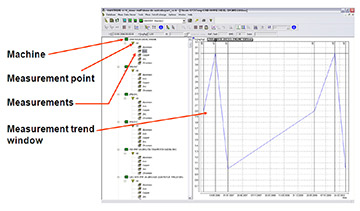

Your vibration software should have the capability to automatically import and export data from and to your CMMS system. Vibration programs like the OMNITREND® software can provide you with the means to address this issue.

Having the ability to automatically share information between your CMMS system and vibration software can be of great value. This capability can allow you to automatically build your vibration database with the same equipment names, equipment IDs, and hierarchy locations that are contained in your CMMS system. This can potentially save your company critical time and expense when starting a new vibration program or updating your current program.

Alarm condition information and much more can easily be shared between your CMMS software and vibration software. This provides the ability to alert your Maintenance Manager, planning and scheduling resources, and other team players about the important equipment conditions found by your vibration program.

Most CMMS and vibration software do not directly share information. Direct storage of data into another program greatly increases the risk of information corruption. Of course, this is never a good thing when it occurs and the risk should be minimized as much as possible. Most CMMS and vibration programs have the ability to map specific information for import and export via a file transfer process. A template is created that determines what information should be exported and in what format it should be stored. The template is stored and automatically executed on a scheduled basis determined by the user. Both the CMMS system and vibration software will create temporary files to share the required information with each other. Each system will automatically import this information and store it in their specific databases(s) from the temporary files. This type of process minimizes your efforts and provides routine and scheduled data sharing between both systems.

This type of data exchange will provide continuity in your reliability efforts and removes confusion when creating work orders based on the defect findings from your vibration program. The result will better integrate your reliability program with your maintenance process.

by Ana Maria Delgado, CRL

Thank you for joining us for our Webinar Detecting Misalignment through Vibration Analysis. We hope you found the presentation to be valuable and very informative. If you missed our Webinar, you can view the recorded version at any time. Watch now!

Here are the answers to your questions:

Q: How do you account for thermal growth when installing new or repaired equipment?

A: If you already know that the machines will move as you run them, you must misalignment them ‘cold’ to compensate, so they grow into alignment as you run them. The trick, of course, is to know exactly how much! There are various methods to ascertain this precisely, the best being to perform a live monitoring job with PERMALIGN® or ROTALIGN® ULTRA Live Trend. To fully answer your question, I’d suggest that you take a peek at our Webinar “Thermal Growth and Machinery Alignment”

Q: If using a dual-channel phase without tacho, do you recommend orientating accels axially for angular misalignment detection and orientating accels radially for parallel misalignment? Is this relative to using 2 channel cross-channel phase to determine angular or parallel phase?

A: Both types of phase measurements are easy to take. The relative phase is the most convenient way to measure phase on a machine because the machine does not need to be stopped to install reflective tape on the shaft. Phase can be measured at any frequency. Most single-channel vibration analyzers can measure the absolute phase. Multi-channel vibration analyzers like the VIBXPERT have standard functions for measuring both absolute and relative phase. See below section “When to use Phase Analysis”

Q: Can’t you only find imbalance from phase?

A: Phase data can be used to verify a lot of vibration issues including imbalance, but it is not only for imbalance itself. I have included a few examples of what issues can be detected below by using phase. Both types of phase measurements are easy to take. Relative phase is the most convenient way to measure phase on a machine because the machine does not need to be stopped to install reflective tape on the shaft. Phase can be measured at any frequency. Most single-channel vibration analyzers can measure absolute phase. Multi-channel vibration analyzers like the VIBXPERT have standard functions for measuring both absolute and relative phase. See below section “When to use Phase Analysis”

When to use Phase Analysis

Everyone needs phase analysis. A phase study should be made on problem machines when the source of the vibration is not clear or when it is necessary to confirm suspected sources of vibration. A phase study might include points measured only on the machine bearings or it can include points over the entire machine from the foundation up to the bearings. The following are examples of how phase can help analyze vibration.

Soft Foot

The term soft foot is used to describe machine frame distortion. It can be caused by a condition where the foot of a motor, pump, or other component is not flat, square and tight to its mounting, or many other things, such as machining errors, bent or twisted feet and non-flat mounting surfaces. Soft foot increases vibration and puts undue stress on bearings, seals and couplings. Soft foot on a motor distorts the stator housing creating a non-uniform rotor to stator air gap resulting in vibration at two times line frequency. A good laser shaft alignment system should be used to verify soft foot by loosening the machine feet one at a time. I’d suggest that you take a peek at our Webinar “Soft Foot”

Phase can be used to identify soft foot while the machine is in operation. Measure the vertical phase between the foot and its mounting surface. If the joint is tight, the phase angle is the same between surfaces. If the phase angle is different by more than 20 degrees, the foot is loose or the machine frame is cracked or flimsy.

Cocked Bearings and Bent Shafts

Phase is used to detect cocked bearings and bent shafts. Measure phase at four axial locations around the bearing housing. If the bearing is cocked or the shaft is bent through the bearing, the phase will be different at each location. If the shaft is straight and the bearing is not twisting, the phase will be the same at each location.

Confirm Imbalance

A once-per-revolution radial vibration usually means rotor unbalance. Use phase to prove imbalance is the problem. To confirm imbalance, measure the horizontal and vertical phase on a shaft or bearing housing. If the difference between the phase values is approximately 90 degrees, the problem is rotor unbalance. If the phase difference is closer to zero or 180 degrees, the vibration is caused by a reaction force. An eccentric pulley and shaft misalignment are examples of reaction forces.

Looseness, Bending, or Twisting

Phase is used to detect loose joints on structures and bending or twisting due to weakness or resonance. To check for looseness, measure the vertical phase at each mechanical joint. When joints are loose, there will be a phase shift of approximately 180 degrees. The phase angle will not change across a tight joint.

Shaft Misalignment

Shaft misalignment is easily verified with phase. Measure each bearing in the horizontal, vertical, and axial directions. Record the values in a table or bubble. Compare the horizontal phase from bearing to bearing on each component and across the coupling. Repeat the comparison using vertical then axial data. A good alignment will show no substantial phase shift between bearings or across the coupling.

Operational Deflection Shapes

Instead of comparing the phase and magnitude numbers from a table or bubble diagram, operational deflection shape software (ODS) can be used to animate a machine drawing. An ODS is a measurement technique used to analyze the motion of rotating equipment and structures during normal operation. An ODS is an extension of phase analysis where a computer-generated model of the machine is animated with phase and magnitude data or simultaneously measured time waveforms. The animation is visually analyzed to diagnose problems. ODS testing is able to identify a wide variety of mechanical faults and resonance issues such as looseness, soft foot, broken welds, misalignment, unbalance, bending or twisting from resonance, structural weakness, and foundation problems.

Phase and magnitude were measured from permanently mounted X and Y displacement probes on a turbine generator. The values listed in the table were used in ODS software to animate a stick figure drawing of the high- and low-pressure turbine shafts and the generator shaft. The picture to the right of the table is a capture from the ODS animation showing the vibration pattern of each shaft and the relative motion between shafts at 3,600 cycles per minute (turning speed).

Many machines vibrate due to deteriorated foundations, looseness, the resonance of the support structure, and other problems that occur below the machine bearings. A phase study might include hundreds of test points measured all over the machine and foundation. Good ODS software can make it easier to analyze phase and magnitude data from a large number of test points. Analysis of an ODS involves observation and interpretation of the machine in motion.

Q: Will coupled drive and belt drive systems show up the same on the spectra?

A: Yes, vibration data on a belt drive system will look different from a coupled drive but not when looking at the common defects of a machine. For example, the vibration data on a belt drive motor will show additional vibration below turning speed due to the belts. The common defects such as imbalance, looseness, and misalignment (to name a few) will show up the same on a belt drive system or a coupled drive system.

Q: In the below spectrum we see a looseness, do we need to correct first the looseness before the misalignment?

A: When looking at vibration data there is always more than one issue showing within the vibration data. I suggest correcting the highest amplitude vibration issue first and the second issue will usually decrease in amplitude. For example, on this vibration spectra, I would suggest correcting the misalignment issue first. The misalignment is the root cause affect of the looseness. Once the misalignment issue is corrected the looseness issue will not be seen on the spectra data.

Q: Will this show up in both horizontal and vertical or is it predominately just one or the other?

A: The answer is that an alignment issue will show up in both the horizontal and vertical orientation when collecting vibration data. Of course, depending on the type of misalignment the horizontal or vertical orientation could be higher. Once a single orientation has a high amplitude level of misalignment it will cross over into the other orientation as well. Of course, if the alignment issue has a small amplitude level it might only be noticed in a certain orientation and again that depends on the type of misalignment that is present.

Q: How can vibration analysis instrumentation be integrated into a building’s BAS computer system?

A: There are generally two different vibration programs that exist in a plant. One would be walk around data collection. This is where a person goes out and places a sensor on a machine to collect the vibration data and then transfers that vibration data in a database. The second would be continuous monitoring where sensors are permanently mounted to a machine. Vibration data is collected every minute or less depending on the need. The walk-around vibration database does have a SAP export feature that would allow you to export certain data from the database over into your system.

In most cases continuous monitoring is best to feed data into another system. We have customers that use our continuous monitoring devices (online systems) to feed into their SCADA systems. This allows for an overall value of 4-20 MA signal to be sent across into another system. Now the other system, like the SCADA, can now alert if certain levels have been reached.

Q: What vibration is typically associated with a damaged impeller or damaged fan blade?

A: The vibration associated with a damaged impeller or fan blades is called vane pass frequency. When looking at the spectra vibration data you would be interested in the number of vanes or impellers that are on the machine. For example, if you had six vanes the vibration data would show a peak in the spectra data at 6 times turning speed, 12 times turning speed, 18 times turning speed, 24 times turning speed, and 30 times turning speed. Depending on the frequency maximum for your spectra would determine how far out the vane pass frequency would occur or be seen.

Q: When we laser align our mechanics say they can’t keep their coupling gap correct. What is a good method to laser align and maintain the coupling gap at the same time?

A: There are two kinds of coupling gaps we have to keep in mind when aligning a machine. The first is the simple gap difference between the coupling faces arising out of any angular misalignment between the shafts, and the second is the axial installation gap specification and tolerance that is demanded by the manufacturer of the coupling.

Typically, you rough align the machines and then set the installation gap of the coupling before you completely tighten it down. If the hubs are shrunk fit, then you guide yourself by the position of the hub on the shaft ends and hope your holes in the base are drilled in the right place when your machines are set down. The correction of any misalignment (angular and offset) typically will never affect the installation gap by enough to make any difference, since we are talking about changes to angularity in thousandths of an inch, whereas the installation gap may have a tolerance of as much as a quarter-inch in or out. So I’m not exactly sure what your mechanics are concerned about. With a good laser alignment system, you perform both angular and offset corrections simultaneously, and the axial gap between the couplings is not a concern.

by Mickey Harp CRL

UPSTREAM PUMPING SOLUTIONS • Spring 2011

Mud Pump Vibration Analysis

Online condition monitoring for hard-to-reach or hazardous places

A mud pump is a reciprocating piston/plunger device designed to circulate drilling fluid under high pressure down the drill string and back up the annulus.

Mud pumps come in a variety of sizes and configurations, but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. A later development is the hex pump with six pistons/plungers.

The normal mud pump consists of two main sub-assemblies—the fluid end and the power end. The fluid end produces the pumping process with valves, pistons, and liners. Because these components are high-wear items, modern pumps are designed to allow for quick replacement.

Vibration Reduction on a Six-Pump Rig

To reduce severe vibration caused by the pumping process, mud pumps incorporate both suction and discharge pulsation dampeners. These are connected to the inlet and outlet of the fluid end.

The number of mud pumps varies per drilling rig depending on the size of the drilling rig. The larger the rig the more mud pumps that will be needed. The mud pumps are considered vital to the operation of the drilling rig. If the mud pumps fail it affects production and can be very costly to repair due to the downtime in production.

Six mud pumps were running on a drilling ocean rig.

The Monitoring System

To avoid any failures of the pumps, an online monitoring system was selected to collect and transmit vibration data back to a software system for analysis. This online monitoring and diagnostic system can also be expanded by a series of program modules (MUXs) that are specific to the application:

- Band analysis module for the automatic evaluation of complex vibration processes in rolling element bearings, gears, or special machines

- Cepstrum analysis

- Orbit analysis

- Data server for the automatic or event-controlled readout of data and for transferring this data to higher systems

Continue reading “Mud Pump Vibration Analysis”

by Mickey Harp CRL

You have invested in a high-precision laser shaft alignment system or vibration data collector/analyzer. Why? Because you want more accurate alignments and vibration measurements, done in less time.

But, what if some incident rendered your tool less accurate, or even wrong altogether? If accurate measurement and tight tolerances are key to your vital processes, this would be a grave concern. Proper operation of your critical machinery or safety systems depends on excellent alignment with low vibration under running conditions.

Perhaps your tool was subjected to temperature extremes, or you dropped your laser or sensor, and even though they are shockproof to the IP-65 standard and didn’t break, they are now out of calibration? What if you are trending data for preventive or planned maintenance, and two different tools used for the same measurement significantly disagree? Only a NIST traceable and certified calibration verification can ensure that your systems are working as designed and within tolerances.

Our highly accurate NIST-certified calibration verifications are performed within a 48-hour turnaround time under tightly controlled conditions to NIST standards in a climate-controlled laboratory. For our laser alignment systems, a biennial check (every two years) is recommended. For vibration data collectors and analyzers, a biennial check is recommended also, or whenever the instrument informs you that one is due.

by Alan Luedeking CRL CMRP

Do you archive your historical vibration data or keep it around forever? If your Condition Monitoring department does not have a plan to deal with database management, then it is critical that you develop one.

Usually, the vibration data has lost any historical value after a couple of years, and keeping this data stored in your vibration database is of limited or no value. Data collected on critical equipment or certain machines may have interesting analytical value and be worth keeping long term. You should decide what data must be stored and for how long. You may find that you have a lot of historical data in your vibration database that is no longer of value.

This data should be moved into another database for long-term storage or completely deleted.

Unwanted vibration data will increase the size of your database(s). This unwanted data can decrease the performance of your vibration software, increase the risk of database corruption issues and cause the loss of the data that you actually do wish to keep long term. Storage of huge amounts of historical data may make your vibration database become unreliable. Some IT departments will charge your department based on the amount of storage space your database(s) consume. Therefore, the storage of extra data could be costing your department additional money monthly and yearly.

Most vibration programs have a means to delete data based upon historical criteria (date ranges) and filter types (equipment types, etc). You may determine that you wish to keep this data archived, but not stored in your primary database file(s). Your vibration software should have the ability to transfer this data to another database. This will allow you to keep the data stored in another location, but remove it from your primary database file(s).

The choice is yours, but you should beware of the positives and negatives of allowing your vibration data to increase year after year. You should devise a plan on what works best for your facility and vibration department and execute this plan on a routine basis (yearly, etc). Some vibration departments will use a specific holiday (New Year, for instance) to remind them that it is time to do database management.

by Ana Maria Delgado, CRL

June 2011 • RELIABLE PLANT

A VIBXPERT® vibration data collector was used to collect data on a DDM 750 AC 1M drilling machine at the workshop to check for factory acceptance. The VIBXPERT allows for high-resolution time signal and spectrum measurements to be collected. The VIBXPERT can collect more than 100, 000 lines of resolution, which allows for the VIBXPERT to capture any transient events that might occur. The vibration data was collected while there was no load on the machine. The main shaft speed was 216 rpm, and the motor itself was turning at 1762 rpm.

After the vibration data was collected, the data was transferred back into the OMNITREND® software for analysis. Vibration analysis on the machine during the Factory Acceptance Test (FAT) detected impacts from the cage (train) in the pinion upper bearing.

See plots and entire case study Condition Monitoring on Drilling Platforms: A Case Study

by Mickey Harp CRL

June/July 2011 • UPTIME

Analyzing only vibration response spectra is difficult since they often don’t clearly match wall chart and textbook examples.

As anyone who has practiced vibration analysis knows, vibration signatures obtained on routes are often far from the wall chart examples. The reason for this is that the vibration signatures collected and analyzed represent the response of a system due to a variety of different forces that act simultaneously to produce one signature.

Unfortunately, vibration analysts are actually interested in determining the individual forces that cause the response. Once the forces are accurately identified, only then can they be reduced or eliminated.

Take for example the force of unbalance. Wall charts and texts on vibration analysis represent mass unbalance as a running speed peak in the spectrum that dominates all other content. Also, these theoretical, or textbook, examples indicate the vibration amplitudes will be equal in the horizontal and vertical planes. However, experienced vibration analysts know this is often not the signature we see. This is due to the fact there are multiple forces acting on the system, and it may have asymmetric stiffness resulting in highly directional vibration. In these situations, following the wall chart examples without additional phase analysis may send an analyst down the wrong path. In order to be effective in vibration analysis, it is necessary to first resolve the most dominant problem and then reanalyze the machine to determine if there are any further forces that need to be minimized. Properly identifying the most dominant problem can be difficult, so make sure to use all tools available. This case history illustrates a situation in which the vibration signature was far from being textbook due to multiple sources simultaneously acting on the system to produce one on-textbook signature. Getting to the root causes of the problem took multiple iterations.

Read the entire article Balancing Out the Root Cause by Chad Wilcox • http://www.pioneer-engineering.com/

by Ana Maria Delgado, CRL

June 2011 • PUMPS & SYSTEMS

Ensure proper bearing assessment and maintenance with this proven method

Of the methods used to assess the operating condition of rolling element bearings, one of the most successful and popular techniques is that of Shock Pulse evaluation. Shock Pulses are a special type of vibration that can be clearly distinguished from ordinary machine vibrations:

• The actual Shock Pulse is the pressure wave generated at the moment when one metallic object strikes another.

• The bulk of the impact momentum, however, acts to deform the target object, which then oscillates at its natural frequency. This vibration ultimately dissipates primarily as heat due to internal friction material damping.

Shock Pulses in Bearings

Shock Pulses occur during bearing operation when a rolling element passes over an irregularity in the surface of the bearing race. Of course, there is no such thing as a perfectly smooth surface in real life. Therefore, even new bearings emit a signal of weak Shock Pulses in rapid succession. This Carpet Value rises when the lubrication film between rolling elements and their races becomes depleted.

A defect on the surface of a rolling element or bearing race produces a strong Shock Pulse reaction with up to 1,000 times the intensity of the Carpet Value. These clusters of high amplitude peaks or Maximum Value stand out clearly from the background noise and are ideal indicators of bearing damage.

Measurement

Shock Pulses propagate within a much higher frequency range than that of ordinary machine vibration, and their energy content is relatively low.

Therefore, the accelerometer used for Shock Pulse measurement is tuned with a 36 kHz resonance frequency that lies precisely within the Shock Pulse frequency range. In addition, a 36 kHz bandpass filter is applied to the accelerometer signal to help filter out lower frequency mechanical vibration. When Shock Pulse is present the tuned accelerometer resonance is excited and amplifies the Shock Pulse signal resulting in an excellent indication of bearing lubrication and damage.

Shock Pulse is responsive even when far more energetic machine vibration is present. Therefore, lower frequency mechanical conditions such as unbalance, shaft misalignment, or vibration from adjacent machines have little effect on Shock Pulse. In addition, high-frequency signals tend to dissipate rapidly so very little interference is encountered from adjacent bearings.

Read the article Reliable Shock Pulse Evaluation of Anti-Friction Bearing Condition

Learn about our VIBXPERT II Portable Vibration Analyzer —with Full Color Display, Fast Data Acquisition and Powerful Vibration Diagnostic Tools. VIBXPERT uses the Shock Pulse method to detect lubrication condition and bearing damage.

by Ana Maria Delgado, CRL

Some vibration software and vibration data collectors allow the use of frequency bands to help the analyst measure and identify specific equipment faults. These frequency bands are actually measured in the vibration data collector. The results can be used for trending and alarm purposes. You can create specific bands around specific faults that may occur in the equipment being monitored. For example, bands for imbalance, misalignment, specific bearing defects, electrical defects, and much more can easily be measured. Alarm thresholds can be created to alert you when attention is required. These bands can help you identify equipment issues in your vibration data before you look at the FFT or time waveform data. A review of the FFT and time waveform data should always be completed. However, band alarms can keep you from overlooking an issue and reduce the amount of analysis that may be required.

by Trent Phillips

June 2011 • TPO Magazine

ACING IT IN OKLAHOMA

Strong skills, preventive maintenance and good planning lead to success at the Coffee Creek Treatment Plant in Edmond.

The Coffee Creek Wastewater Treatment plant in Edmond, Okla., has had near-perfect compliance for 38 years and has won several awards, most recently 2010 Large Wastewater Plant of the Year from the Oklahoma Water and Pollution Control Association (OWPCA).

It all has happened with a staff of five, despite rapid population growth, several upgrades, and various episodes with collection system inflow and infiltration. “When you have only five staff, you have to focus on working smarter, not harder,” says Fred Rice, water resources superintendent for the city. This means preventive maintenance, SCADA monitoring of critical alarms, and ongoing equipment and safety training.

It’s also a matter of teamwork. Kris Neifing, chief plant operator, hired in 2004, supervises two operators, a maintenance specialist, and a lab technician, and is also responsible for one lift station at the plant and nine lift stations located throughout the collection system.

Rice credits Neifing and his staff for the plant’s track record. “Kris has really pulled everyone together as a team,” he says. “All the credit for what we’ve achieved in the last six years is due to Kris and his staff. My role is like coaching a sports team. You can coach them, but the team executes the plays.”

Says Neifing, “What makes us successful is that everybody has different skills that collectively make us the best we can be. Some are better at maintenance while others prefer operations. We believe that no one knows how to do their jobs better than the ones who do it every day.”

Continuous improvement

The plant’s compliance and safety record do not mean the staff is complacent. “We strive to continuously improve,” says Rice. “There is no process out there that can’t be improved, especially on the maintenance side.”

Rice and Neifing frequently attend the WEFTEC conference and other trade shows to check out the latest equipment. This has led to several innovations, such as vibration analysis and laser alignment equipment to help ensure that pumps and motors operate normally with the lowest possible maintenance. Rice and Neifing also read trade journals and network with others in the wastewater treatment business to glean ideas.

“The staff comes to us with ideas, like getting air compressors for maintenance, and suggesting better equipment or ways of doing things,” Neifing says. “We empower them to make suggestions, and we listen.” Adds Rice, “The city started a program based on the general concepts in the Good to Great book because we believe that organizations that excel are successful from the ground up. We give our employees responsibility and then hold them accountable.”

Read the entire article Acing it in Oklahoma

by Ana Maria Delgado, CRL

March 2011 • IMPO MAGAZINE, iPurchase Supplement

As the American economy recovers, how aware, or active, are manufacturers concerning predictive maintenance?

Most manufacturers never lost the desire to increase their overall reliability and predictive maintenance efforts during the recent economic slowdown. Some companies did postpone purchases of predictive maintenance-related products. However, a lot of companies realize that an investment in predictive maintenance technologies is a viable means to decrease overall maintenance expenses, so they do it the right way. A lot of manufacturers, as a result of this understanding, continued to invest in predictive maintenance-related technologies during the recent economic slowdown. This allowed them to reduce overall maintenance costs and place their company in a more competitive position once the economy recovers. Interest in these products is higher this year as companies continue to invest in vibration- and alignment-related products to reduce their costs. increase competitive advantages, and manufacture equipment reliability.

Read the entire interview Q&A Roundtable from iPurchase, a supplement from IMPO Magazine including:

Are there any interesting trends occurring in the maintenance market?

Why do you think laser alignment is important to a manufacturer’s maintenance strategy?

How would you recommend a manufacturer approach the creation of a more robust maintenance plan?

by Trent Phillips

by Ana Maria Delgado, CRL

MYTH: A well-trained technician can predict within a window of a few hours when a machine will fail.

TRUTH: This myth is common throughout industry and poses a danger to machinery. The myth often leads to operating machinery with known defects for periods longer than is safe for the equipment. Let’s explore the elements that brought about this myth and why it remains so prevalent.

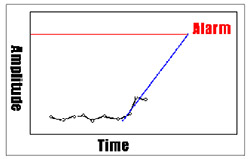

One reason for the birth of this myth is the curve fitting plots found in many PDM software programs. Figure 1 shows such a plot. Those not trained in the use of the software may think that the time projected for the condition to reach the alarm level indicates “time to failure”. In reality, the projected time is “time to alarm”. The machine may run quite sometime after exceeding an alarm. These plots are very valuable if used as intended.

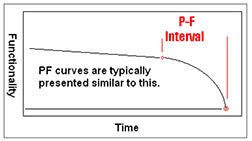

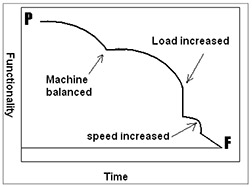

Another reason for this pervasive myth is that published PF curves are almost always shown as downward exponential curves. Figure 2 shows a typical curve. If PF curves really are this shape, finding the “time-to-failure” would simply be a mathematical process. However, PF curves are seldom this shape because many variables may influence the shape of the curve. Figure 3 shows how a real curve may look and also presents some reasons why the shape is erratic. PF curves may have hundreds or thousands of shapes.

Even the best-trained technicians, using the best tools can’t possibly know all variables that may lead to component or machine failure. Load, speed, temperature, and environment are only a few of the many variables that may affect “time-to-failure” for a given defect. A well-trained technician can detect defects and may even be able to state with a fair amount of confidence that a machine will operate or will not operate until the very first opportunity to take it out of service for repairs. Doing otherwise and operating with known defects is tantamount to rolling the dice and gambling with your machinery.

by Bill Hillman CMRP

February 2011 • WORLD CEMENT

Robert Schmaus, Prüftechnik Condition Monitoring GmbH, Germany, outlines the benefits of applying online condition monitoring systems.

What is condition monitoring?

Condition monitoring is the process of monitoring machinery health or machinery condition, such that a significant change is indicative of a developing failure. It allows maintenance to be scheduled, or other actions to be taken to avoid the consequences of failure before the failure occurs. The main goal of condition monitoring, therefore, is to improve plant production capacity and make the process more profitable. Different maintenance strategies have been adopted by maintenance personnel – starting from pure ‘breakdown maintenance’ (run the machine until breakdown without intervention), preventive or time-based maintenance(scheduled maintenance stops), to predictive maintenance. Having adopted a predictive maintenance strategy- in a plant, maintenance stops for interventions required are scheduled according to machine conditions and not by mere periodical interventions, as is the case in time-based maintenance. Predictive maintenance enables operators to take advantage of the lifetime of machine components and minimizes required spare parts stock, as repairs are effectuated according to the condition of machines and not on a periodical basis. As developing failures can be detected in time, consequential damages are avoided. Improved machine reliability minimizes interruptions to the production process.

Download the entire article Online CMS – Value for Money?

by Ana Maria Delgado, CRL

Oil data reports made available by laboratories to their customers are usually delivered in MICROSOFT EXCEL® files or text files. The data is generally made available via an online download. These reports contain information on many different substances found in the oil such as iron, aluminum, copper, and many more. Other factors such as viscosity are included as well.

Oil analysis data provides a great insight into the health of your equipment and should be a routine part of any good reliability program. It can be overwhelming to process all this data in a meaningful way. You may not wish to trend and alarm on every single parameter contained in the oil report. So what do you do? The answer may be your vibration analysis software!

A good vibration analysis program like OMNITREND will allow you to create customizable imports for your oil analysis data. A routine and automated process can be set up to import only the data of interest for specific machines. Once the data is imported, then automated alarms can be created to alert you of any oil parameters that are of concern for your equipment.

Oil data can be visually trended over time and you will automatically be alerted when an oil parameter reaches a value of concern for a specific machine. This can allow you automatically manage selected oil parameters of concern and greatly reduce the amount of time required to manually review each parameter measured by your oil analysis lab.

Furthermore, it will allow you to use the routine vibration data collected and oil analysis data provided by your laboratory to detect and confirm equipment problems. You should not underestimate the power of having your vibration and oil analysis data integrated.

by Ana Maria Delgado, CRL

MYTH: “It is acceptable to use a stinger attached to the vibration sensor.”

TRUTH: Stingers can be attached and used with most vibration sensors. However, stingers are the least desirable method to mount the sensor to the equipment. Stingers reduce the frequency range that can be measured with the attached sensor. Also, it is very difficult to use the same amount of pressure to hold the sensor to the equipment each time. This may further reduce the signal response as well as the consistency and quality of data.

MYTH: “Applying generic overall amplitude values allows the correct trending and identification of equipment faults.”

TRUTH: An overall level is a single number representing the amplitude of a vibration measurement. Overall values can be derived in many different ways. You should be very cautious when assigning generic and/or the same alarm values to your equipment. Similar machines can operate at different vibration levels. The individual characteristics of each machine should be taken into consideration when setting valid alarm levels.

MYTH: “Collecting vibration data quarterly, semiannually, or annually on equipment will identify all equipment defects.”

TRUTH: The collection frequency of vibration data should be determined based on several factors. Some of these factors are equipment load, the operational speed of the equipment, operational frequency, criticality, and more. It is possible to calculate the optimal measurement frequency required to routinely identify equipment defects. Assigning some collection frequency based upon manpower or other means almost always results in equipment failures that were not detected in time or at all by the vibration program.

by Trent Phillips

March 2011 • WindPower Engineering

Condition-monitoring systems have made it clear that wind turbines are complex machines in which overall vibration values must be systematically determined and evaluation references made available. Points to consider when writing evaluation guidelines for wind-power plants include:

• Function and structural design of wind turbines and their components

• Interaction between the individual drivetrain components (modules) being tested

• Information and experience regarding the possible faults and damages occurring in the individual testing modules during operation and their economic impact

• Knowledge of operation-related and machine-related vibration influences, the diagnostic procedures that must be adhered to, and their respective limits

The recent VDI 3834, established and released in 2009, takes into consideration the special requirements for evaluating wind turbine components. The guideline is set for turbines ranging from 100 kW to 3 MW.

Read our article Finally, ISO Guidelines for Condition Monitoring

by Alex Nino CRL