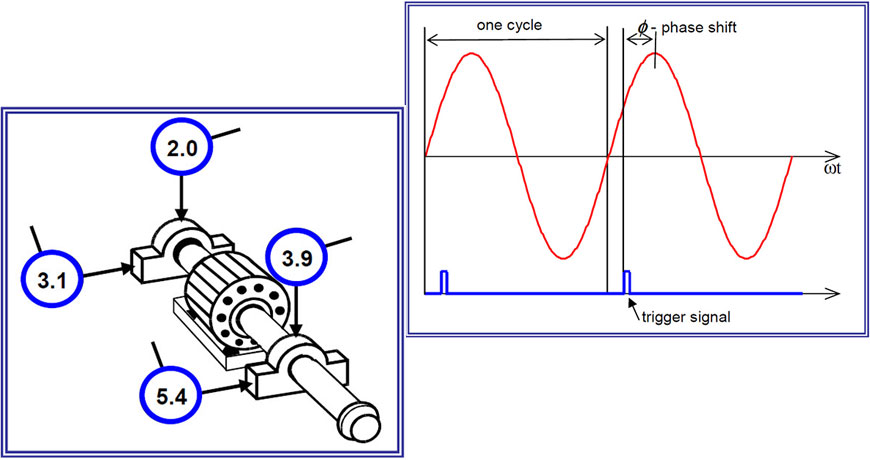

First one must know what the definition of phase is in the reliability world. Phase is simply the relationship between two events. There is absolute phase that is usually measured as either “phase-led”, which is from the peak in a filtered time waveform to the tachometer, or once per revolution indicator, or “phase-lag” which is from the tachometer or once per revolution indicator to the peak in a filtered time waveform. Of the two, phase-lag is probably the most common.

There is also relative phase which takes two filtered time waveforms and compares the phase between the two. Generally your Channel One or A (as the case may be) is stationary and you can move Channel Two or B from position to position and get the indicated phase. Relative phase can be a time saver as the user can get an indicated phase without shutting down the machine to put reflective tape on the shaft for a laser or optical pick-up. This can be used to verify or diagnose unbalance, misalignment, and looseness, etc., but it cannot be used for dynamic balancing which requires absolute phase for repeatable calculations. Whichever type of phase is used, you can use it to identify and/or confirm unbalance; check the phase on each side of the coupling as well as across the coupling to determine misalignment and what type of misalignment. Note: Always remember the orientation of the sensor as motion towards an accelerometer is positive energy in the time waveform and motion away from the accelerometer is negative energy in the time waveform.

The user can place the sensor on each side of a junction where two surfaces come together and look for a phase shift which indicates the two surfaces are not tight to each other. This could be looseness between a motor foot to the base, or from the base to the sole plate, or from the sole plate to the foundation, or even from the foundation to the slab. If everything is tight then the machine will move as one.

Phase can also be used to look for cocked bearings, bent or bowed shafts and other things as well.

Our advanced vibration analyzers, along with phase analysis, can help you better diagnose fault conditions.

Featured Graphics taken from Vibration Diagnostics report by Alena Bilosova and Jan Bilos – Ostrava 2012

by Diana Pereda

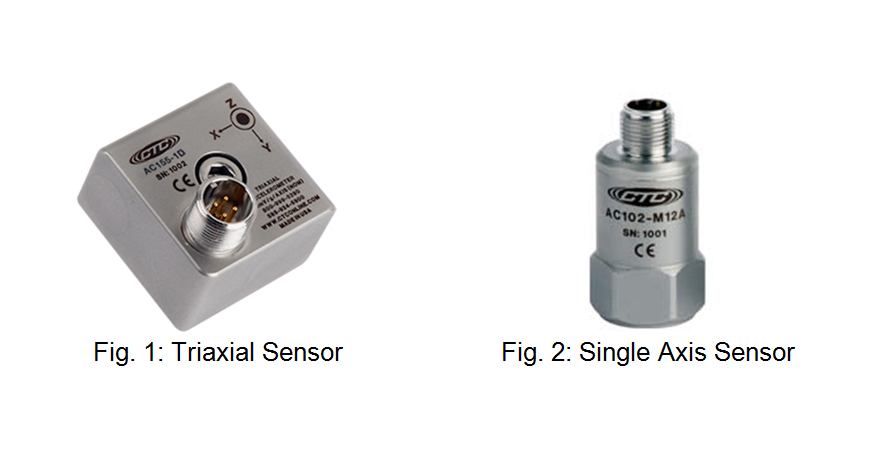

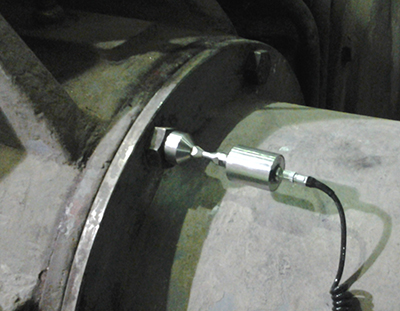

First off, “triax” is short for “triaxial accelerometer sensor”. A triaxial sensor has three (tri) separate sensors (that collect data in the X, Y, and Z directions) contained in one housing, compared to a single axis sensor in a normal accelerometer.

There are many pros and cons to using a triaxial sensor. A few things to consider:

- Cost

- Position

- Data frequency

- Time

The triax sensor (Fig. 1) is more expensive than the single axis sensor (Fig. 2). When using the triax sensor, it has to be mounted in the same orientation each time or the directions will not match the data that was collected before. Many places sell triax mounting pads to make certain that the sensor is locked in a certain orientation to ensure correct data collection. This represents an additional cost, and time must also be budgeted to mount the pads. Do not mix sensors when collecting data. If the same motor is having vibration data collected using a triax sensor, then do not collect data another month with a single axis sensor. A single axis sensor will need to be moved three times to the correct orientation for data collection whereas the triax was mounted in just one position. This could affect the trending of your data.

The VIBWORKS vibration instrument allows for both triax and single axis data collection. The VIBWORKS is a true four-channel instrument. This allows the instrument to collect data in all three directions at once. Normally three directions are taken per bearing on equipment. Depending on the setup and the equipment, it could take up to 20 seconds per direction to collect and save the vibration data. On a normal motor-fan machine train this means 12 directions which would take around 4 minutes to collect vibration data on, using a single axis sensor. Using a triax sensor it would only take 80 seconds to collect vibration data on the entire machine train.

When selecting a triax sensor, make certain that the vibration instrument is not multiplexing the vibration channels. For example it the instrument is only capable of two channels it will collect two channels at the same time and then collect the third channel separately. This means it would take almost three minutes to collect data as all three channels are not being collected at the same time.

by Diana Pereda

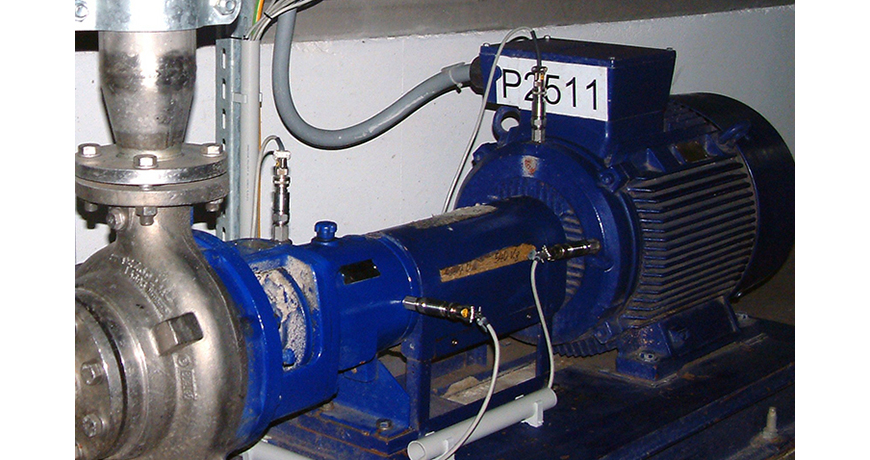

Where to place the vibration sensor depends on what data you wish to see. Certain defects show up better in the horizontal direction while other defects show up better in the vertical direction. So which location should I choose to place my vibration sensor? Most sensors in use today are single-axis sensors, so generally 95% of what they pick up or detect is in line with the sensor. Therefore, since placement of the sensor is crucial, some thought should be given as to what data shows up best in which of the three directions—vertical, horizontal, and axial. Data taken in the vertical direction will typically show looseness better than in the horizontal direction (at least on a horizontally mounted piece of equipment); however the horizontal will show unbalance better than the vertical. Axial vibration will show angular misalignment better than a radial reading will.

Also, it should be considered that in the real world there are times that the sensor cannot be placed directly on a bearing, such as with the non-drive end bearing on an electric motor due to the fan cover; on large motors this cover can extend 10 in. or more from the bearing, and considering that rolling element bearing generate high frequency data in early stages of failure and high frequency data only travels short distances, the data can and will be diminished the further from the bearing that you take your reading. In these cases you simply get as close as possible to the bearing knowing the generated signal may be diminished; in such case you should pay special attention to the frequencies present as they may be at lower levels than expected. If you are dealing with vertical equipment it’s typically stiffer in-line with the discharge than perpendicular to the discharge and that will affect your data as well.

For more information on a vibration tool to collect and analyze your sensor data, check us out!

by Diana Pereda

When using phase to determine how a machine is moving, the orientation of the sensor mounted on the machine is extremely important. In Figure 1 below one sensor is attached to the motor’s outboard (non-drive) end in one orientation, and on the other inboard (drive) end, it is mounted in the opposite direction.

Because the sensors are attached to the motor’s ends opposite one another the resulting phase angles would be 180 degrees opposed to each other. To correct for this, the user has to choose a reference location and then correct the measured phase angle for any sensor locations where the sensor position is opposite the reference.

For measured phase readings of less than 180 degrees the user would add 180 degrees to the measured phase angle and for measured phase angles that are greater than 180 degrees the user would subtract 180 degrees from the measured reading.

In most applications this occurs most often in the axial direction of measurement; however, sometimes due to obstructions, the user cannot physically place the sensor in the same orientation as the reference sensor in the horizontal or vertical axis.

Just as with the axial direction, the user will have to determine a reference location and then correct the measurements for any locations where the sensor position doesn’t match the reference location.

Figure 2 below is what is commonly called a “Bubble Diagram”. The bubble diagram is used to record the vibration amplitude and phase angle at all machine locations in the machine train in the vertical, horizontal and axial directions.

As previously stated, the analyst must determine if any sensor measurement locations will require the sensor to be attached to the machine differently and adjust the phase readings at locations different from the reference accordingly.

The easiest way to keep track of reference directions and location is to draw a little arrow as shown below in Figures 3 and 4. If the arrow is pointing towards the machine this indicates that the phase angle was recorded directly as indicated.

When the arrow is pointing away from the machine as shown above in Figure 4, the phase angle recorded in the bubble diagram is 180 degrees opposed from what was actually measured.

Source: Practical Solutions to Machinery and Maintenance Vibration Problems by Update International

Our advanced vibration analyzers, along with phase analysis, can help you better diagnose fault conditions.

by Diana Pereda

Guest post by Suzane Greeman, ASQ-CMQ/OE, CAMA, CAMP, CMRP, author of the Risk-based Asset Criticality Assessment (R-b ACA©) Handbook. Suzane is the Principal Asset Management Advisor of Greeman Asset Management Solutions Inc.

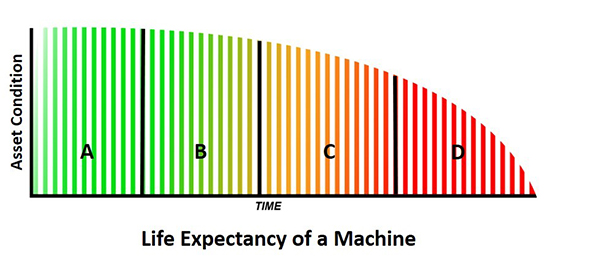

Asset Condition Management

Asset failure is the most common form of risk that is managed in industrial plants. One key element of asset risk management is asset condition management. Asset condition is a factor in determining the probability of an asset’s failure. Asset condition is important when developing asset management plans and when prioritizing CapEx and OpEx (TotEx) funds. In fact, a company with a good understanding of how the conditions of critical assets are changing over time has a good line of sight to emerging risks and what it will cost to treat them.

In developing an asset condition program, two main strategies are used to ascertain an asset’s condition. One is Condition Monitoring (CM) and the other is Condition Assessment (CA).

Condition Monitoring (CM) is a quantitative technique that uses instruments to detect component degradation and predict impending failure. Instruments rely on a consistent relationship between their components and the environment to numerically derive the data. For this reason, they are more consistent and precise and deemed to be more objective. Examples of condition monitoring applications typically found in industrial plants include infrared thermography, oil analysis, precision alignment, ultrasonic inspection, vibration analysis, and motor current signature analysis. Some types of condition monitoring are applicable to both static and rotating assets. Infrared thermography, for example, may be applied to switch gears, pipelines and gearboxes.

Condition Assessment (CA) is a qualitative methodology that uses innate human senses and the judgment of experienced technicians to detect component degradation and predict asset failure. In executing condition assessment, assets are inspected by a qualified person, and condition attributes are qualitatively graded according to a pre-defined scale which is then used to identify component degradation over time. This method is still considered qualitative even when numerical scales are added. Condition assessment may also be applied to both static and rotating assets. The most common type of condition assessment applied to industrial plants is the visual inspection.

Given the subjective and inconsistent nature of the human judgment, an instrument that is properly calibrated would be deemed to produce higher-quality asset condition data than data whose sources for which human judgment is the source.

Deriving Value from Proactive Asset Condition Management

The asset condition strategy is an asset management activity that should be determined as part of an overall asset management plan. Condition assessment and condition monitoring are not mutually exclusive. Assets could have both strategies, for example, a motor could have a maintenance strategy that includes both visual inspections, vibration, and oil analysis. Factors influencing the asset condition strategy include the use of RCM and other requirements in the operating context such as legal requirements for pressure vessels.

Proactively managing asset condition allows asset risks to be holistically managed, leading to the creation and protection of asset value. Whatever the final asset condition strategy, executing the asset condition plan should be done via the organization’s work management system. To be useful as asset information for decision-making, asset condition data should be managed in the CMMS/EAM so that it can be analyzed and reported.

Establishing asset condition, as significant as that is, does not prevent or correct asset failures. Failures are mitigated by the proactive actions of the organization. The true value, therefore, of an asset condition program, is in identifying and predicting component degradation and allowing for long-term asset planning and timely mitigation of catastrophic failures.

Check out these upcoming asset management courses from Greeman Asset Management Solutions Inc.:

by Ana Maria Delgado, CRL

Necessary equipment information needed for a successful vibration database can and will vary greatly depending on the person being asked. This variation is due to their involvement with the process; for some, plant criticality defines what they believe to be important; for others, it may be how often a piece of equipment fails.

Generally we would like to have the basic machine configuration such as motor-pump, motor-gearbox-fan, is there belt driven equipment, etc. Also needed are the speeds in RPM or Hz of each shaft involved. What type of bearings—fluid film or rolling element, and their part numbers, as well as coupling type—grid, toothed, fluid, or even rigid. Also needed is mounting type: solid or isolated or set up on boards.

The more information the better, though a program can and is usually started with much less. At a minimum have shaft speeds and bearing type and number of vanes on an impeller or blower wheel. Additional information can be added such as actual bearing part numbers, and the number of stator or rotor poles on a motor, which your motor repair facility should be able to provide. The more information that a vibration database contains the faster the analysis process and the better its accuracy.

Take a look at our Vibration Analysis Tools!

by Yolanda Lopez

An overall level is a single number representing the amplitude of a vibration measurement. Overall values can be derived many different ways. You should be very cautious when assigning generic or the identical alarm values to your equipment. Similar machines can operate at different vibration levels. The individual characteristics of each machine should be taken into consideration when setting valid alarm levels. Even a simple vibration check revealing acceleration, velocity, unbalance or bearing noise can help you find and prevent equipment faults. You don’t need a sophisticated system for this; just a simple but good handheld tool (such as the EASY-LASER XT280) can help you with this.

An overall level is a single number representing the amplitude of a vibration measurement. Overall values can be derived many different ways. You should be very cautious when assigning generic or the identical alarm values to your equipment. Similar machines can operate at different vibration levels. The individual characteristics of each machine should be taken into consideration when setting valid alarm levels. Even a simple vibration check revealing acceleration, velocity, unbalance or bearing noise can help you find and prevent equipment faults. You don’t need a sophisticated system for this; just a simple but good handheld tool (such as the EASY-LASER XT280) can help you with this.

by Ana Maria Delgado, CRL

Is it bearing information, number of poles, frame size, number of gears, impellers, blades, horse power, operating voltage, motor type, manufacturer, number of belts, sheave size, or tooth count? Nope! None of the above.

All of the above information is great to have when analyzing vibration data, but the single most important item that is always required is the running speed of the equipment.

Not knowing the true running speed makes vibration analysis impossible for determining the proper defect to be reported. For example, if the speed was recorded at 1,780 RPM, but the true speed was 3,560 RPM and a high peak at 3,560 RPM is present; it could lead the analyst to believe that the 2× turning peak is related to another issue. Having the proper running speed of the equipment will assist the analyst in making the correct diagnoses for the equipment.

Once the correct turning speed has been identified the spectrum can be broken into three types of energy: sub-synchronous, synchronous, and non-synchronous.

Having this information available can assist the analyst when analyzing the vibration data.

Related Blog: Finding the running speed of a machine

by Yolanda Lopez

In every facility there are pieces of equipment that are critical to the daily operation of the plant. Those machines are the ones that keep you awake at night. If the equipment fails or has a break down unexpectedly it has an adverse effect on production. An online vibration system can assist in giving you peace of mind for the health condition on that equipment.

Using an online system allows for monitoring of critical equipment 24 hours a day, 7 days a week, and 365 days a year. The ability to email or text alerts when alarm thresholds are met or exceeded allows for early detection of failures.

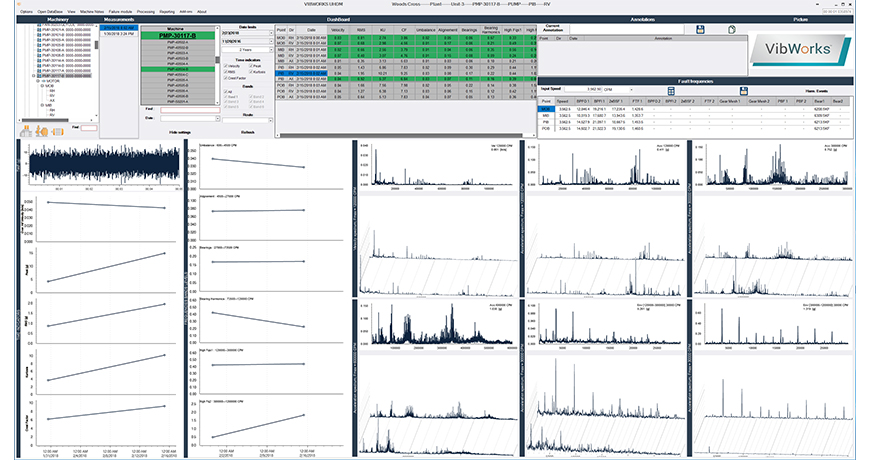

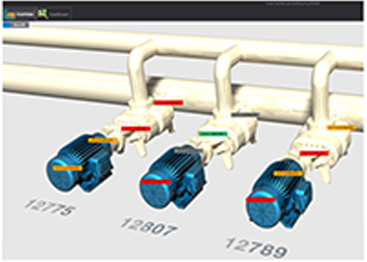

The CORTEX MONITORING SYSTEM (CMS) is a cost-effective, scalable solution, dedicated to the prediction of asset failure and the prevention of catastrophic failures and costly repairs. This innovative system will help you optimize your performance by monitoring the condition of your valuable assets with highly accurate diagnostic tools. CMS allows for easy access to the condition of the equipment at any time and from any place. The software can be accessed via the cloud using IIoT protocols and easily viewed on a phone, tablet, or any internet capable device. The images below show examples of what can be displayed using an internet capable device.

by Yolanda Lopez

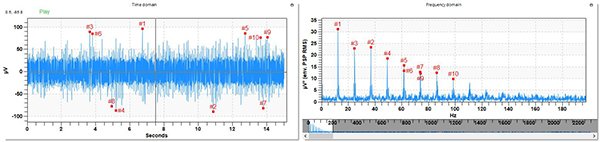

Every analyst develops their own process for analyzing vibration data. This is generally learned from others, being around to observe or communicate with, or from training the individual receives. Often, the person collecting the data will be the same person that analyzes the data. The process could include that during the data collection the person not only uses the vibration data collector but also collects physical data from their senses such as sound and smell to see what is going on with the equipment. They ought to look for material under the coupling guard to see if an elastomer coupling is shedding pieces, which may indicate misalignment; look at the oil level if possible for signs of oil leakage; look at the mechanical seal area to identify other leakage. Once data is collected one would generally look for anything outside of established alarm levels, look at the spectrum to see where the highest amplitude peak is at, look for other high amplitude peaks or groups of peaks and harmonic families, and look for sidebands around peaks to help in identifying the source. You would also look for the direction of the highest vibration. Examine the historical data too: you would want to look at the rate of change to determine how quickly failure is approaching. Also never, never forget to look at the time waveform as all data comes from the time waveform. I try to look at the time waveform in the raw units of the sensor as that can verify what you may be seeing in the spectral and give you a greater understanding of just how bad a problem you may be facing.

If you need a solution to help ease this process, consider our BETAVIB vibration analysis systems.

by Yolanda Lopez

When the breakdown/repair cycle becomes routine, you can bet money is being wasted. The psychology of manufacturing (if we can call it that) is very much overlooked.

Q: What if it was a personal affront to everyone in the plant, management, production, and maintenance, for a machine to break down? Seriously. What if everyone viewed it as a personal failure when a machine failed unexpectedly? Do you think the necessary attention would be given to it? That might be revolutionary.

Of course, if too much time and effort are put into something, the cost will exceed the return, but if the necessary serious attention is given to an operating asset by EVERYONE, the next excellent idea that improves reliability could come from anyone.

“Ownership” is something we know to be beneficial in a manufacturing facility. We know that the more “personal” everyone feels toward the assets, the better they take care of them and the more creative they are about caring for them. When we feel that personal attachment of ownership, we are more forthcoming with our efforts and supportive of the efforts of others who share our valuation of the assets.

With this in mind I offer the following suggestion in order to tap into that inherent pride of ownership and personal attachment that many have to the company and assets of their occupation: LET EVERYONE SEE HOW UGLY IT IS!

Hang a sign on a machine that failed and shut your plant or process down. The sign should read,

This machine FAILED and shut our plant down:

Failed: August 30th, 2011

Failed: May 4th, 2015

Failed: January 19th, 2017

Failed: August 11th, 2018

And keep adding the dates. This way the bad actors become obvious to everyone, and even the MTBF will be obvious. The absence of a sign on a machine could then be as informative as the signs with dates.

If you can succeed in creating ownership of reliability that cuts across department lines, the benefits could be enormous. Failures come from all directions: Operations, maintenance, engineering, management, and procurement. Let everyone see the ugliness of it and encourage everyone to pull together to make it beautiful (or at least more attractive.)

by Yolanda Lopez

- Knows how to use the software package they have.

- Knows how to use the hardware they have.

- Knows where to place the vibration sensor to ensure good data.

- Knows how to recognize bad data.

- Knows what to look for while collecting data besides just the vibration sensor.

- Knows how and to whom to report their findings so that repairs are made, and gets feedback on the repair.

- Knows when to ask for help.

Learn more about LUDECA Vibration Analysis Courses

by Yolanda Lopez

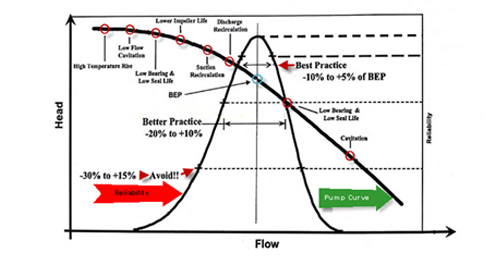

Centrifugal pumps have a specific design point at which they operate most efficiently. This sweet spot is known as the BEP (Best Efficiency Point) which provides the design engineer with the required flow and pressure while also providing the best efficiency. If the pump has been specified incorrectly or is placed into a system that doesn’t have the proper system head, the pump will become a reliability problem child. When a centrifugal pump is placed into a system without the required system resistance, the pump will run off its curve to the right, resulting in early bearing and mechanical seal failures and impeller damage caused by cavitations. If the pump is placed into a system with excessive system resistance, or, as frequently happens, the pump discharge valve is throttled early, bearing and seal failures occur along with impeller problems caused by discharge recirculation. Best practice dictates that the pump be specified and designed to operate within +5% to –10 % of its designed BEP. This will result in lower operating and maintenance costs and a happy pump.

by Yolanda Lopez

There are many different reasons to consider and implement an online vibration system. Some of the key reasons are:

- The equipment is critical to production.

- The equipment has a long repair time.

- The parts for the equipment have a long lead time.

- The equipment is not easy to access.

- The equipment is in a remote location.

- Equipment failure could endanger the environment or people.

Online systems like the CORTEX by BETAVIB allow not only vibration to be monitored but also many additional parameters (such as speed, temperature, pressure, and flow, to list just a few), all of which can also be monitored and recorded. In addition, a customized overview can also be created to allow anyone to quickly monitor the health of the equipment using red, yellow, and green alarms that will indicate if an issue is present.

The CORTEX Monitoring System (CMS) is a cost-effective, scalable solution, dedicated to the prediction of asset failure and the prevention of catastrophic failures and costly repairs. This innovative system will help you optimize your performance by monitoring the condition of your valuable assets with highly accurate diagnostic tools.

by Yolanda Lopez

This blog post concerns rolling element bearings and not journal bearings.

When a rolling element bearing begins to deteriorate the damage usually manifests itself in one of the races (either inner or outer) followed by the rolling element, and finally the cage. When the races begin to have defects these tend to excite the natural frequencies of the race which typically show up beyond the maximum frequency that most analyzers collect data to.

When a rolling element bearing begins to deteriorate the damage usually manifests itself in one of the races (either inner or outer) followed by the rolling element, and finally the cage. When the races begin to have defects these tend to excite the natural frequencies of the race which typically show up beyond the maximum frequency that most analyzers collect data to.

The specific defect frequencies are determined by the bearing geometry. One would normally start seeing peaks in the FFT spectrum in the 5× to 7× range and sideband peaks spaced at 1× rotational speed. As the defects progress, harmonics of the component defect frequency will move lower in the FFT with more harmonics showing, while the number and amplitude of the sidebands increases as well.

When you begin to see the defect frequencies of multiple components, then this indicates that the damage is progressing. In the time-waveform’s early stages you will see an increase in the amplitude of the peaks, indicating impacting; as damage increases the amplitude of the impacts will increase and for a time the pattern will resemble what is known as the “angle fish” pattern. This pattern will not last and may not even be seen depending on the frequency of the data collection. The pattern tends to go away because of continued deterioration of the bearing components.

by Yolanda Lopez

In most cases, when equipment is in failure mode, it begins to make sounds that are not commonly heard during normal operating conditions. Once this sound is heard a defect (at least one) is already present in the equipment.

Using our vibration tools can assist in detecting the defect before that sound is heard with the naked ear.

Think of a vibration sensor as a stethoscope that allows a vibration instrument to listen to the heartbeat of the equipment. The heartbeat is then recorded and data can be viewed historically for that equipment. The data can then be compared to other readings collected on the equipment to quickly see if any changes have occurred.

by Yolanda Lopez

Guest post by John Lambert at Benchmark PDM

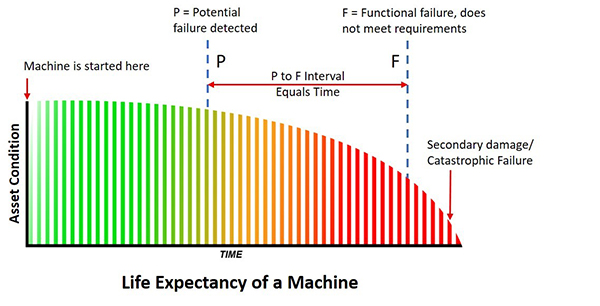

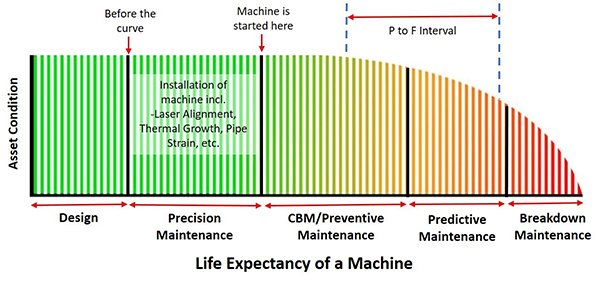

Recently I have been seeing the P to F interval curve popping up a lot on my LinkedIn feed and in articles that I have read. It was a concept that I was first introduced to when I was implementing Reliability Centered Maintenance into the Engineering and Maintenance department at the plant where I worked at the time. It was a great idea, that if done correctly is a maintenance benefit. Why, because it’s cost savings and cost avoidance. Let me explain this.

The P to F curve was used as a learning tool for Condition Based Maintenance. The curve is the life expectancy of a machine, an asset. The P is the point when a change in the condition of the machine is detected. The F is when it reaches functional failure. This means that it is not doing the job it was designed to do. For example, if it were a seal that is designed to keep fluids in and contamination out and is now leaking, it’s in a state of functional failure. Will this put the machine down? Probably not, but it depends on the importance of the seal and the application. This is an important point because the P (potential failure) is a fixed point when you detect the change in condition but the F (failure) is a moving point. Not all warnings of failure put the machine down very often you have options and time. Consider this: If I have a bucket that has a hole in it, it is in a functional failure state. But can I still use it to bail out my sinking boat? You bet I can!

Failure comes at us in many ways and obviously, we have many ways to combat it. If you detect the potential failure early enough (and it can be months and months before actual failure) it means that you can avoid the breakdown. You can schedule an outage to do a repair. It’s not a breakdown, the machine hasn’t stopped, it’s no downtime. This is cost avoidance and the plant can save on the interrupted loss of production because of downtime costs.

There are a lot of examples of cost avoidance and also of cost savings. For instance, at the plant I worked at we used ultrasound to monitor bearings. We detected a very early warning in the sound level and were able to grease the bearing and the sound level dropped. We saved the bearing of any damage, and we saved a potential breakdown so this is cost savings. Even if there is some bearing damage, the fact that we are aware of and monitor the situation lets us avoid any secondary damage.

It’s one price to replace a seal and it’s more if you have to replace a bearing in a gearbox. However, it can be very expensive to have to replace a shaft because the bearing has sized onto it and ruined it. Secondary, ancillary damage can mount up very quickly if you don’t heed the warning you are given with the P of potential failure. This warning of potential failure gives you time before any breakdown. The earlier the detection, the more time. Time to plan, and view your options. And what people tend not to do is failure analysis while the machine is still in service. A failure analysis gives you a great start on seeking out the root cause but starts right away, not when the machine is down.

Condition monitoring or as it’s often called Condition-based maintenance (CBM) does work. However, for me, there is a downside to this and I will explain why shortly. CBM is based on measurement, which is good because we all know to control a process we must measure.

Consultants (and I’m guilty) like to put labels on things and you may see:

1. Design, Capability, Precision Maintenance

2. CBM, Predictive Maintenance

3. Preventive Maintenance

4. Run to Failure, Breakdown Maintenance

For me, the P to F interval curve starts when the machine starts. That means Design and Precision Maintenance is not in the curve and this happens before startup. A small point but it takes away from the interval meaning.

We use predictive maintenance technologies in CBM. Vibration, Ultrasonic, Infrared, Oil Analysis, NDT (i.e. pipe wall thickness), and Operational Performance. They are all very good technologies, yet it is a combination of cross-technologies that works best. As an example, vibration may give you the most information yet ultrasound may give you the earliest warning on a high-speed bearing. And then there is oil analysis which may be best for a low-speed gearbox. It all depends on the application you have which dictates what’s best for you. A lot of time and effort was placed on having the best CBM program and buying the right technology.

This, I believe, lead to the maintenance departments putting the focus on Condition-based maintenance! This I think is wrong because we still have failure. This means that CBM is no better than Predictive Maintenance. This doesn’t mean that I don’t recommend CBM, I do. To me, it’s a must-have but it does not improve the maintenance process because you still have machine failure. Machine failures fall into three categories Premature failure, Random failure, and Age-related failure. We want the latter of these. We know from studies that say that 11% of machine assets fail because of age-related issues. They grow old and wear out. This means that 89% fail because of some other fault. This is a good thing because it gives us an opportunity to do something about them.

These numbers come from a very famous study by Nowlan and Heap (Google it!) that was commissioned by the US Defense Department. It doesn’t mean these numbers are an exact reflection of every industry but the study but it has stood the test of time and I believe it has led to the development of Reliability Centered Maintenance. But let’s say it’s wrong and let us double the amount they say is age-related (full machine life expectancy). That would make it 22% and 78% would be the number of random failures. Even if we quadruple, it’s only 44% meaning random is at 56% and we are still on the wrong side of the equation. The maintenance goal has to be to get the full life expectancy for all their machine assets.

In order to get the full life expectancy for a machine unit, I think you have to be assured of two things. One is the design of the unit which includes all related parts (not just the pump but the piping as well). The other is the installation.

If you’re like me, and you believe that Condition Based Maintenance starts when the machine starts then you understand that there is a section of the machine’s life that happens before. You could make an argument that it starts when you buy it because, as we all know, how we store it can have an effect. However, what is important at this stage is the design and installation of the machine. In most cases, we do not design the pump, gearbox, or compressor but we do size them so that they meet the required output (hopefully). We do quite often design the piping configuration or the bases for example. All of which is very important but the reality is that maintenance departments maintain already-in-place machine assets. So, although a new installation, requiring design work is not often done, installation is. Remove and Refit is done constantly. And the installation is something that you can control. In fact, it’s the installation that has the largest influence on the machines’ life. The goal is to create a stress-free environment for the machine to run. No pipe strain, no distorted bases, no thermal expansion, no misalignment, etc.

Precision Maintenance was a term I first heard thirty years ago. It’s part of our M.A.A.D. training program (Measure, Analyse, Action, and Documentation). It’s simple, it means working to a standard. Maintenance departments can set their own standards. However, all must agree on it and adhere to it. This is the only way to control the installation process. This is the way to stop random failure and get the full life expectancy for your machine assets. The issue is that we do not have a general machinery installation standard to work to. Yes, we can use information from other specific industry sources such as the American Petroleum Institute (API) or the information from the OEM (both of these are guidelines) however nothing for the general industry as a whole. Well, this is about to change. The American National Standard Institute (ANSI) has just approved a new standard that is about to be published. I know this because I worked on it and will be writing about it shortly.

If you look at the life cycle of a machine, we need to know and manage the failure as best we can. If we only focus or mainly focus on the failure, we will not improve the reliability of the machine. We cannot control the failure. What we can control is the installation and done correctly this will improve the process giving the optimum life for the machine.

I sell laser alignment systems as well as vibration instruments. If a customer were to buy a vibration monitoring tool before they bought a laser system. I would think their focus is on the effect of the issue, not the cause. What do you think?

by Ana Maria Delgado, CRL

1. A Change in the Quantity of Grease Consumed

Maintenance departments track their grease consumption to monitor and control costs. A change in consumption is a sure sign that your lubrication program is on the right track. Most organizations are guilty of over-lubricating. Expect lower grease consumption as your program matures. Bad procedures lead to bearings routinely receiving more grease than they’re designed to handle. The excess ends up being pushed into the motor casing or purged onto the floor.

Over lubrication happens when re-greasing intervals are scheduled based on time instead of condition. Control lubrication tasks with ultrasound to monitor the condition and maintain optimal friction. The time between greasing intervals increases, resulting in less grease used per bearing.

2. Fewer Lube-Related Failures

Do you track failures and perform root cause analysis?

Organizations with optimized greasing programs experience fewer lube-related failures. Less fixing and fire-fighting translates to more creative time for maintenance. Use that time to bring more machines into the greasing program.

Additionally, with ultrasound, you find many non-trendable defects. For example, broken or blocked grease pipes and incorrectly fitted grease paths prevent grease from reaching the bearing.

3. Optimized MRO Spares Management

Your new and improved lubrication program is delivering wins; better control of grease consumption, fewer failures, and more productivity for maintenance. Use this time to study trends and better manage your storeroom.

A decrease in bearing-related failures improves spares optimization. Share your ultrasonic lubrication data with your MRO Stores manager to create a plan to reduce the number of emergency parts on hand.

Since you’re taking stock, why not shift some burden to your suppliers? Ask them to confirm your emergency parts against their own stock. If it can be supplied on the same day then it doesn’t need to be on the balance sheet.

4. Increased Number of Machines Monitored

One benefit of an effective lubrication program is time.

• Time allotted to monitoring machines instead of fixing them.

• Time allotted to correctly assessing the real needs for lubrication.

• Time to look at the big picture.

Take, for instance, criticality assessment. Many lubrication programs begin with small steps. All the “A” critical machines receive priority, and rightly so. But what about the rest? With more time to plan, organize, and schedule, the number of machines acoustically monitored for optimal lubrication increases.

5. Save Time. Combine Acoustic Lubrication and Condition Monitoring

You worked hard for these results. It’s time to use your data for more than just lubrication.

Acoustic lubrication is the proven method to ensure precise bearing lubrication. New technology from SDT, LUBExpert, combines the power of onboard lubrication guidance with Four Condition Indicators for bearing condition assessment.

The time savings from assessing bearing condition during the lubrication process is beyond valuable and another sign your acoustic lubrication program is on the right track.

6. Inspector Confidence at an All-Time High

Reliable machines are the product of an effective lubrication program. You have:

• Managed grease consumption

• Fewer grease related to bearing failures

• Optimized MRO spares

• More machines under watch

• Increased data collection intervals

The power of adding ultrasound to your greasing program delivers win after win for reliability. Reliability breeds confidence. More confident inspectors making the right calls and infecting a positive culture throughout the organization.

by Allan Rienstra - SDT Ultrasound Solutions

1. Collect the best data you can, using a high-quality ultrasonic data collector.

2. Consistent sensor placement must fundamentally be observed.

3. Identifying boundaries that impact data transmission is imperative.

Ultrasound is Shy… It Keeps Boundaries

Think of ultrasound as the quiet introvert. It prefers to stay in, and rarely mixes well with ultrasounds from other places. We call this “boundary behaviour” and it’s another characteristic that makes ultrasound such an attractive condition monitoring technology. Ultrasound signals remain isolated to their source, making it easy to pinpoint defects without interference from other elements of the machine.

Sensor Placement

Inspectors tempted to place their ultrasound sensor directly on the gearbox cover should reconsider. This common mistake affects data integrity. A gasket seals the cover plate to the gearbox housing. The specific acoustic impedance of the gasket material differs greatly from the cast metal of the gearbox. The change in materials a boundary barrier through which bashful ultrasound is reluctant to be passed. A better option is to place the sensor on a bolt head, which is directly connected to the gearbox housing. The result is crystal clear ultrasound signals for listening, trending, and condition assessment. HearMore: Click here to listen to Damaged Gearbox.

Special thanks to our partner Allan Rienstra from SDT Ultrasound Solutions for sharing his great knowledge with us!

by Allan Rienstra - SDT Ultrasound Solutions

With the proliferation of online monitoring systems utilizing permanently mounted sensors, users will need to beware of “direction sensitive” vibration and possible sudden unexpected failure due to insufficient data. The thought of insufficient data may seem incredible when thinking of constantly monitored equipment, but consider the all too common (IMHO) practice of uni-directional (one direction) monitoring of machine trains.

Many installations, due to initial cost, are mounting a single vibration sensor at each bearing. While this may be sufficient for most equipment trains, most of the time, it will certainly not be sufficient for all equipment trains all of the time. Although I don’t have hard data available, if I were to make a statement based on personal experience, and anecdotal evidence from other practitioners, my statement would be something like this: “80% of horizontal equipment could be pretty well monitored by sensors mounted at the horizontal radial position on each bearing.” I say pretty well monitored because I just can’t bring myself (as an analyst) to be completely satisfied without the vertical and axial data.

This setup would catch virtually all unbalance and roller bearing faults (excluding thrust bearings), some to most misalignment faults, and a sprinkling of others. I use the word “catch”, to mean it would give an indication of a developing problem. Accurate diagnosis of unbalance, misalignment, bent shaft, and even looseness in many cases (as well as a host of other possible faults) would require more data.

If the online vibration program manager takes these facts into account and governs the program accordingly, they should be pretty successful. If they add to the online program a “full battery” vibration survey, maybe semi-annually, just to catch the less common, but possibly very destructive defects that could develop undetected by the uni-directional monitoring, they would most likely be very successful.

What could be so destructive and yet be completely undetected by the uni-directional sensors? The Big R for one is Resonance. Resonance is often extremely directional. Consider a case history LUDECA co-published with one of our customers in the December 2012 Wastewater Processing magazine:

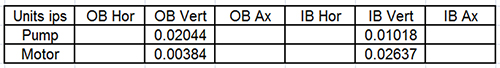

In the table below (Figure 1), the 1× amplitudes are displayed. I have hidden all but the vertical data, as though it were monitored only by vertical sensors.

Everything is wonderful right? Look at the motor outboard vertical, only 0.00384 inches per second—very impressive. Of course, at this point you are thinking “he is setting me up for something” and you are correct. Even though most anyone would love to have these amplitudes on virtually any machine, this particular machine was tearing itself apart with vibration!

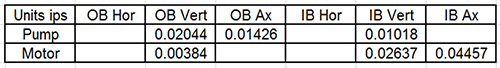

We will give the reader a little more data, just to help add emphasis to the directional nature of resonance. We will add the axial data to our table in Figure 2:

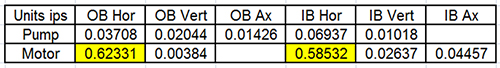

Still very, very good… so far. Now, look at Figure 3, with the addition of the horizontal data.

The motor outboard horizontal amplitude is 162 times the amplitude of the motor outboard vertical! What if the user had only vertically mounted sensors? What about vertical with the added information of axial? You may be thinking “if I had only horizontal sensors, I would have been ok”, and for sure you would have been better off than having only vertical. You would at least have known you had a problem, but you would not have known what that problem actually was. You would likely have assumed the vertical and axial are probably vibrating badly too.

Hopefully, you would have verified the vibration in the other directions. As it was, the user had data from all directions and a simple glance told the analyst with a high degree of confidence what the problem was. Resonance is almost alone in creating that kind of directional disparity.

To reiterate, the online vibration program manager should be successful if they take into account the fact of limited data and supplement the online program with a “full battery” vibration survey at a cost-effective interval, just to catch the less common, but possibly very destructive defects that could be developing undetected by uni-directional monitoring.

by Mike Fitch CRL