Guest post by Suzane Greeman, ASQ-CMQ/OE, CAMA, CAMP, CMRP, author of the Risk-based Asset Criticality Assessment (R-b ACA©) Handbook. Suzane is the Principal Asset Management Advisor of Greeman Asset Management Solutions Inc.

Asset Condition Management

Asset failure is the most common form of risk that is managed in industrial plants. One key element of asset risk management is asset condition management. Asset condition is a factor in determining the probability of an asset’s failure. Asset condition is important when developing asset management plans and when prioritizing CapEx and OpEx (TotEx) funds. In fact, a company with a good understanding of how the conditions of critical assets are changing over time has a good line of sight to emerging risks and what it will cost to treat them.

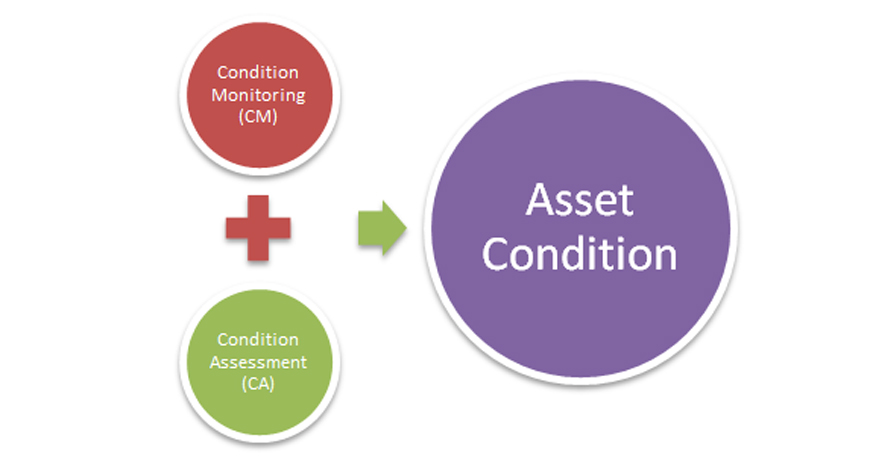

In developing an asset condition program, two main strategies are used to ascertain an asset’s condition. One is Condition Monitoring (CM) and the other is Condition Assessment (CA).

Condition Monitoring (CM) is a quantitative technique that uses instruments to detect component degradation and predict impending failure. Instruments rely on a consistent relationship between their components and the environment to numerically derive the data. For this reason, they are more consistent and precise and deemed to be more objective. Examples of condition monitoring applications typically found in industrial plants include infrared thermography, oil analysis, precision alignment, ultrasonic inspection, vibration analysis, and motor current signature analysis. Some types of condition monitoring are applicable to both static and rotating assets. Infrared thermography, for example, may be applied to switch gears, pipelines and gearboxes.

Condition Assessment (CA) is a qualitative methodology that uses innate human senses and the judgment of experienced technicians to detect component degradation and predict asset failure. In executing condition assessment, assets are inspected by a qualified person, and condition attributes are qualitatively graded according to a pre-defined scale which is then used to identify component degradation over time. This method is still considered qualitative even when numerical scales are added. Condition assessment may also be applied to both static and rotating assets. The most common type of condition assessment applied to industrial plants is the visual inspection.

Given the subjective and inconsistent nature of the human judgment, an instrument that is properly calibrated would be deemed to produce higher-quality asset condition data than data whose sources for which human judgment is the source.

Deriving Value from Proactive Asset Condition Management

The asset condition strategy is an asset management activity that should be determined as part of an overall asset management plan. Condition assessment and condition monitoring are not mutually exclusive. Assets could have both strategies, for example, a motor could have a maintenance strategy that includes both visual inspections, vibration, and oil analysis. Factors influencing the asset condition strategy include the use of RCM and other requirements in the operating context such as legal requirements for pressure vessels.

Proactively managing asset condition allows asset risks to be holistically managed, leading to the creation and protection of asset value. Whatever the final asset condition strategy, executing the asset condition plan should be done via the organization’s work management system. To be useful as asset information for decision-making, asset condition data should be managed in the CMMS/EAM so that it can be analyzed and reported.

Establishing asset condition, as significant as that is, does not prevent or correct asset failures. Failures are mitigated by the proactive actions of the organization. The true value, therefore, of an asset condition program, is in identifying and predicting component degradation and allowing for long-term asset planning and timely mitigation of catastrophic failures.

Check out these upcoming asset management courses from Greeman Asset Management Solutions Inc.:

Filed under:

Condition Monitoring by Ana Maria Delgado, CRL