1. Collect the best data you can, using a high-quality ultrasonic data collector.

2. Consistent sensor placement must fundamentally be observed.

3. Identifying boundaries that impact data transmission is imperative.

Ultrasound is Shy… It Keeps Boundaries

Think of ultrasound as the quiet introvert. It prefers to stay in, and rarely mixes well with ultrasounds from other places. We call this “boundary behaviour” and it’s another characteristic that makes ultrasound such an attractive condition monitoring technology. Ultrasound signals remain isolated to their source, making it easy to pinpoint defects without interference from other elements of the machine.

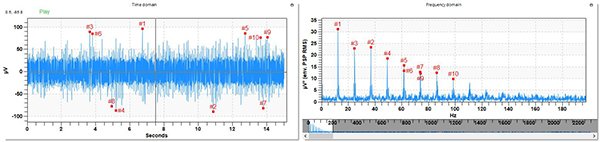

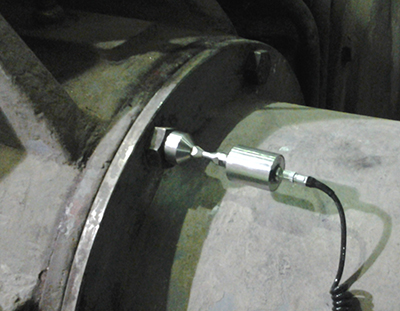

Sensor Placement

Inspectors tempted to place their ultrasound sensor directly on the gearbox cover should reconsider. This common mistake affects data integrity. A gasket seals the cover plate to the gearbox housing. The specific acoustic impedance of the gasket material differs greatly from the cast metal of the gearbox. The change in materials a boundary barrier through which bashful ultrasound is reluctant to be passed. A better option is to place the sensor on a bolt head, which is directly connected to the gearbox housing. The result is crystal clear ultrasound signals for listening, trending, and condition assessment. HearMore: Click here to listen to Damaged Gearbox.

Special thanks to our partner Allan Rienstra from SDT Ultrasound Solutions for sharing his great knowledge with us!

Filed under:

Condition Monitoring, Maintenance Tips, Ultrasound by Allan Rienstra - SDT Ultrasound Solutions