When you are planning on attending a training course there are a few things you as a student should do. These could include some simple things such as:

1. When making hotel arrangements, consult with the person/company providing the training and ask for a list of recommended hotels. They may negotiate special rates with certain hotels or they may know the hotels that are the most convenient to the location.

2. Always ask for and review the training agenda/syllabus.

3. Allow extra space in your luggage to carry back the training materials you will be given during class.

4. Ask questions during the course (there are no “dumb” questions). If you don’t understand something ask —there is always a first time to learn anything. Not understanding something and not asking hurts only you.

5. If possible use the software and/or instrument prior to the class as this can help you formulate productive questions and you will gain much more from the course.

6. Remember that if you’re not rested you will not get the full benefit of the course —do not let your nighttime enjoyment compromise your ability to focus on the training material each day.

7. If you’re unhappy with something in the class tell the instructor either during class or on a break. The instructor wants you to have a productive training experience. The instructor cannot help you if you do not make your questions or concerns known. Remember, courses should be targeted to the average experience in the class and not for the most advanced participant or for the novice either.

Check to see if your equipment needs any calibration or repairs prior to attending the class. Make arrangements to have these repairs or calibration completed while you are attending the training course. This is the perfect time to have these types of things completed.

by Gary James CRL

UPTIME • October/November 2013

“Many different tools have been used over the years to detect changes in machinery condition. The human hand, eye, and ear have been the oldest tools used to detect conditional changes in machines. It is important to understand the value and limitations of our human senses.”

Most machines give some indication that a potential component failure is about to occur that will lead to a functional failure. Our goal should be to identify, monitor, and correct components that are failing before they create a functional failure that will prevent the machine from performing as intended. Condition Monitoring is a primary tool used for this process. For example, a bearing defect is an example of a potential failure. The bearing would be monitored for degradation and replaced before it completely fails, preventing the machine from performing its intended function (functional failure.)

It could be argued that God created the first condition monitoring instrument when he created man. Our main senses are touch, sound, sight, taste, and smell. Additionally, humans have other senses that can detect balance, heat, pain, etc. All of these senses can provide very valuable data about the environment around us and the equipment we work with each day. Therefore, the human being is the first CM instrument to be used—versatile in application and proven to be very a beneficial tool.

Download my entire article Moving Beyond our Human Senses

by Trent Phillips

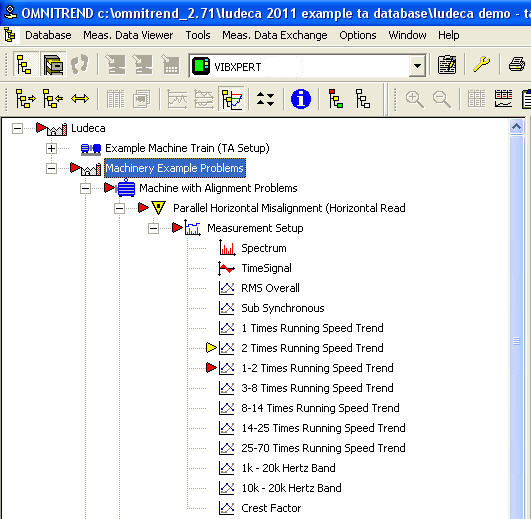

A successful condition monitoring program is only as good as the database for it that is configured by the end-user. A condition monitoring database should be treated as a living entity. The database can only grow and fulfill its main objective by constantly having information added to it to continuously strengthen the database.

When creating a new condition monitoring database a lot of unknowns exist about the machinery. The most important piece of information that is vital in vibration analysis is the correct running speed of the machines that are designated for monitoring. Common unknown items might include bearing types and models, the number of vanes or impellers, and gear ratios. Most of the equipment in your facility will need repair over the next few years.

Once the machines have been repaired or internal parts replaced, these unknown items can be identified. It is important to notify the appropriate maintenance personnel to collect this information for you as the opportunity arises in the future. Adding the identified items into the condition monitoring database allows for the vibration analysis to be performed with greater certainty.

Another vital item to add to and update in a condition monitoring database is machinery-specific alarms. Smart alarms have the ability to save you 50% of analysis time when analyzing vibration data. Do you need to look at every spectrum and waveform that is collected every month? With properly set alarms the problem machines can be found a lot more easily by the simple colors assigned when an alarm is triggered. Alarms can be set to automatically trigger when specific fault conditions develop. With a few clicks of the mouse, the machine and measurement that is in alarm can be viewed. Of course, having the proper set alarm levels will be a benefit when looking for machines that have issues. Alarm levels can be obtained from many different sources, but the best alarms are the ones tailored for the specific machine that is being monitored. Alarms need to be tweaked on an annual basis so that a new adaptive alarm can be set for the machines. A four-year-old alarm setup on a machine before it was sent out for repair might not have the best current alarm settings needed for that machine.

LUDECA offers a service in which we can tune up your existing database. This can be done remotely or onsite. A database assessment is completed on your database to make certain proper data is being collected as well as tweak your current alarms as needed. Additional items are also updated and completed. If interested please contact us for more details.

by Mickey Harp CRL

With Training funds being difficult to obtain these days it is critical that we do everything possible to have a satisfactory and productive training experience. This includes evaluating whether it would be more cost-effective to attend a training class off-site (such as at a vendor’s facility) or have the course conducted at your facility.

With Training funds being difficult to obtain these days it is critical that we do everything possible to have a satisfactory and productive training experience. This includes evaluating whether it would be more cost-effective to attend a training class off-site (such as at a vendor’s facility) or have the course conducted at your facility.

There are advantages and disadvantages to both. Typically, if multiple personnel from your facility will be attending it could be more cost-effective to have the course presented in-house at your facility. This would eliminate travel costs, per diems, etc. for your personnel. If only one or two individuals are attending, then it might be more cost-effective to attend the course off-site at the vendor’s training center. Also, attending a course off-site may remove you from the internal distractions and interruptions that occur from being in the plant environment during the training course. When you decide to attend a training course you have the right to expect that the course will be presented in a professional manner by an instructor who knows the material and subject matter.

by Gary James CRL

Most of us use the Internet to email our friends, review sports scores, read the news, or entertain ourselves. Management usually frowns upon employees using the Internet during working hours, for valid reasons.

Nevertheless, the Internet can be a valuable work tool and it is important that you and your management understand the ways in which the Internet can provide value to your work.

A vibration analyst can use the Internet to research important equipment information (bearing information, drawings, etc) that can greatly enhance their analysis efforts. The internet can be used to take a Condition Monitoring (CM) training course. For example, the analyst can use the Internet to take a vibration analysis certification course. This prevents the employee from having to travel, and spend time away from their family and their job. This reduces employee stress and saves the employer money. A good technology provider can use the Internet to log into the computer remotely to help install software, provide training, and troubleshoot problems. A good technology provider can supply remote analysis support through the Internet as well. This can save a lot of money because the support can be instantaneous and the provider does not have to travel to your location.

The items described above and many more are now possible by utilizing the Internet as a tool. It is very important that you and your management (especially your IT people) understand the value of full internet access for your CM team.

by Trent Phillips

Good condition monitoring software will have capabilities that allow importing of critical process data into the CM database. Information such as temperatures, pressures, equipment speed, etc., are very important to the vibration analyst or other CM analyst. This information provides additional parameters to help the analyst understand and confirm the results uncovered during their analysis.

by Trent Phillips

We all become instantly nervous when we get some type of notification from the IRS. Are we about to be audited? This is almost never a pleasurable experience to be looked forward to.

We all become instantly nervous when we get some type of notification from the IRS. Are we about to be audited? This is almost never a pleasurable experience to be looked forward to.

A Condition Monitoring (CM) technology and methods audit, on the other hand, can be very valuable. Have you considered having an outside source audit your vibration analysis program or other CM technologies? Management is usually aware of the cost of having this done but is not usually aware of the value it provides.

Having someone audit your vibration analysis program or other CM technology can save you multiple of its cost in return. If done correctly the audit process can be completed quickly and provide valuable results. It can help you ensure that you are using your technologies to their fullest potential. It can be used as a training activity. You may not be aware of the analysis opportunities you have been missing and how the CM technology can be better applied to the specific needs of your facility.

Help management understand the value an audit could provide. You may be allowed to use this type of service to learn and move your vibration analysis program or CM technology to the next level. CM technology audits, unlike an audit from the IRS, can actually be quite pleasurable.

by Trent Phillips

Are others in your plant or corporation aware of the capabilities of the Condition Monitoring (CM) technology you utilize and all that you do with it? It is critical that management, maintenance employees, and production employees are aware of what you do and the value CM technologies provide. This will make them much more responsive to your needs and efforts and make your job much easier as a result.

Consider taking a maintenance or production employee along when you do data collection and show them how you use this information for analysis of equipment problems. Hold level of awareness meetings and invite plant management and employees to attend. This will allow you to expose them to the capabilities that you and the CM technologies offer. The goal is not to turn them into analysts, but to help them better understand the value of CM efforts.

by Trent Phillips

A plant that is unreliable cannot be safe. As a plant becomes more reliable it becomes a safer working environment. Safety incidents decrease because less work is required on the equipment, fewer equipment failures occur which creates unsafe conditions, etc. Reliability breeds safety!

How is your facility using reliability efforts such as Condition Monitoring to create a safer working environment?

Have you had discussions with your Safety Department about the value that reliability efforts such as CM provide to the overall safety of your plant?

by Trent Phillips

Condition Monitoring (CM) tools have become smaller, lighter, faster, and more sophisticated in recent years. Functionality that once was limited to a computer in an office can now be easily done in the field with the right CM analysis tool. It is now possible to do complete equipment analysis at the machine. Modern Condition Monitoring tools have very sophisticated root cause analysis capabilities as well. This is very important because a condition monitoring program should go beyond the identification of potential failures in equipment like bearing issues, etc. that lead to functional failures and downtime. A good condition monitoring program will include root cause activities that identify the reasons behind equipment issues (why the bearing, etc. developed an issue). These activities will help your equipment reliability efforts move to the next level.

Is your facility simply identifying conditional changes in equipment for repair or working toward identifying the root causes of those conditional changes?

What processes are you using for root cause identification and analysis?

by Trent Phillips

Most equipment failures are not age-related. The equipment will provide some sign of impending failure if we have the right tools available to understand the change in condition.

A lot of facilities assign monitoring intervals based upon arbitrary schedules such as 30, 90, 180, or 365 days.

Often this is due to a lack of understanding of how equipment fails, misunderstanding of how conditional tasks such as vibration analysis work, available labor, and lack of importance placed upon Condition Monitoring (CM) efforts. These arbitrary collection intervals can actually lead to failures that go undetected and a loss of value from the effort. The equipment will tell you how often monitoring must be completed. Not understanding this can lead to costly results!

How does your facility determine the correct monitoring intervals for CM efforts? Is it based upon manpower, gut feel, P-F Interval, or what someone told you to do?

by Trent Phillips

Engage, support, train, provide direction, and set goals for those involved in the Condition Monitoring (CM) effort. Otherwise, they will most likely make poor decisions on your behalf. Unfortunately, most reliability efforts fail. This can be due to a change in management focus and the lack of importance placed on reliability efforts such as Condition Monitoring. Management has to demonstrate consistent signs that reliability efforts are important to the overall business goals of the company and ensure that the results of those efforts are continually implemented.

It is important to create realistic expectations! Understanding the value and limitations of the CM technology is important as well. Make sure that data collection and analysis activities are completed at the correct intervals to detect conditional changes in the equipment being monitored and that the findings are properly documented.

It is critical to ensure that the recommendations of the condition monitoring technology are implemented. It serves no purpose to generate findings that will maintain and/or improve equipment health and not implement the results (do the recommended work). Do not make the CM program a “part-time effort”. Doing so will almost guarantee the failure of the effort.

Design, installation, startup, and the operation of the equipment are the biggest contributors to reliability or lack of reliability within a plant. Engineering, maintenance, production, and reliability efforts are interdependent. Collaboration is important between these groups and Management has to promote this effort. CM efforts create reliable capacity. Plant capacity is not of much use if it is not reliable! It is important that CM efforts be integrated into all of these areas. Additionally, it is important to make sure that considerations are taken when purchasing and maintaining spare parts. This process can have a great impact on equipment reliability.

What tips do you have so that Managers can have a successful Condition Monitoring program within their facility?

by Trent Phillips