Reliable Plant, August 2010

Traditionally, plumbness measurements on a vertical hydro-turbine/generator shaft involved stringing a series of wires along the length of the shaft, attaching a weight to the end of the wires, and then measuring the space from the wire to the shaft using an electronic micrometer. Although this method was inexpensive and has been used for many years, it did require access to a long length of the shaft to achieve an accurate resolution. Also, measurements involve physically measuring the distance between the wire and the shaft at various elevations on the shaft, increasing the amount of time and personnel requirement for the measurement. Ludeca presents its experience with a laser-based system that replaces the time-consuming wire method. Measurements now can be performed in a fraction of the time it would otherwise take with the wire measurement method. Ludeca’s measurement system, known as the PERMAPLUMB, uses a self-adjusting mechanical mirror, always plumb to earth, that reflects a Class 1 laser beam into a detector. It requires only 14 inches of axial space along the shaft.

The mirror and transducer are attached by a bracket that uses magnets on the turbine shaft. From a single 270-degree shaft rotation, the system calculates and displays angularity and corrective moves and provides a statistical quality measurement of the data. A “move” function allows monitoring of corrections as they are being made. The resolution is better than 0.00002 inches per foot, which is more accurate than required by NEMA. Adjacent turbines also can continue to operate since the system is insensitive to vibration.

Read our article: How to achieve vertical shaft plumbness using laser alignment

by Daus Studenberg CRL

July 2010 · IMPO Magazine

“You must be the change you wish to see in the world.” — Mahatma Gandhi

Investing in more efficient process machinery makes good business sense and will help to ensure reduced costs plus a greener plant. However, not all plants can afford to replace their present equipment with newer, more efficient machines. What steps can these plants take to “green up” their business and operate more efficiently? Most plants can vastly improve machine reliability, efficiency, and reduce raw materials conversion costs by simply making improvements in their present machinery. This can be done through precision maintenance practices and defect elimination. A good PdM (predictive maintenance) process will help to achieve these goals.

Read the entire article: Save Some Green: Green Up Your Machines

by Ana Maria Delgado, CRL

Problem: Our boiler feed water pump running on steam turbine kept failing numerous mechanical seals since 2006, and gave us very poor reliability. Due to the unreliable nature of the steam turbine, we had to keep running our electric boiler feed water pump as a primary pump. This cost us $$$ in terms of energy usage, as we were not able to use steam generated by our boiler to power the steam turbine pump.

Solution: In February 2010, we ordered a new rotating assembly for the steam turbine pump and installed it. We also purchased a new laser shaft alignment system “OPTALIGN SMART®”. We had stopped laser aligning our equipment for the last couple of years due to the old laser alignment system not being calibrated and not being very user-friendly. After seeing a hands-on demonstration of the OPTALIGN SMART, our skilled trade group was convinced that we needed this new user-friendly system for laser shaft alignments. Upon laser aligning the steam turbine, we found that we were way off in both Horizontal and Vertical alignment. Using the OPTALIGN SMART, we were able to achieve a much better alignment than we ever did. We did not get the “smiley” faces on our alignment, but that was due to having a tremendous amount of pipe strain, poor base condition, and being bolt-bound. However, our steam turbine has been running smoothly without any issues since February 2010.

According to some operators, the steam turbine has never run this quiet and long in the past. We have started using the OPTALIGN SMART laser shaft alignment tool on all our rotating equipment, and have already seen some really good results and overall cost savings in maintenance labor and materials. —Nihal Raval, Maintenance/Reliability Engineer with SOLUTIA

by Ana Maria Delgado, CRL

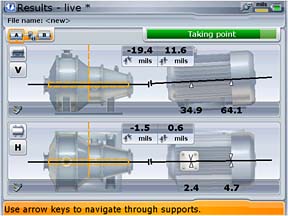

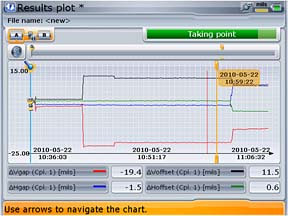

The biggest contribution one can make to lower the operating costs of rotating systems is to align them correctly using the real coupling target values. Target values recommended by manufacturers do not always reflect the real machine centerline movements due to thermal growth, pipe strain, and dynamic factors. The new ROTALIGN® ULTRA Live Trend, a short-term continuous monitoring application, helps to exactly determine the relative positional changes between coupled machines during start-up or shut-down. By applying these values, the machines are precisely aligned to reflect normal operating conditions. In addition, Live Trend allows you to establish a trend of the events that influenced such positional changes. With Live Trend, you can also monitor pipe growth and any other machine components over time.

- Lower energy costs through reduced power consumption

- Increased mechanical life of bearings, seals, shafts, and couplings

- Reduced bearing and coupling temperatures

- Minimized breaking or cracking of shafts

- Reduced vibration

- Reduced machine damage

Reliability starts with precision shaft alignment!

by Ana Maria Delgado, CRL

The following situation occurred at a Municipal Power Plant. During a planned outage, the on-site team was utilizing a Rotalign® Pro with Boralign® to assess the position of the bearing bores after the removal of the rotor on an Allis Chalmers power generation steam turbine. The results were varying far more than normal and the customer wanted to understand why. I was called in to make sure there were no errors in the use of the Boralign system. The tool was being used properly and there were no problems with the tooling. The customer had already set the unit up on a surface plate and established that there was no appreciable drift with the tool. I suspected excessive vibration, so I used my Vibscanner® to measure overall vibration in displacement. No significant level of vibration could be detected; certainly not enough energy to cause the level of non-repeatability they had been observing in the readings. I thought if the movement of the lower shells had a very low frequency that was too slow to measure utilizing traditional vibration sensors and methods, I might be able to measure it with the Rotalign Pro Straightness program. Both the laser and receiver were mounted on standard magnetic dial stands with brackets that are part of the Straightness hardware set. A series of points were established on the lower shells to measure between, both along the rotational axis and from side to side. Setting the Rotalign Pro Straightness program to the shortest sample time and observing the X-axis values over a 2 to 4-minute period, I was actually able to see a very slow movement between various points on the lower shells. While some areas of the lower shells were reasonably stable, there was movement between some points that was as much as .024”, but at a very low CPM. While this process was somewhat like ODS, there was no real-time phase data, so I could not tell how the various points were moving relative to each other. It was still very helpful to the rotating engineer to understand how much the various areas were moving. Better yet, with a fairly simple program and only 6 hours invested in collecting the data, the rotating engineer had a good idea of the magnitude of the problem.

by Keith Van Hentenryck

July 2010 · Maintenance Technology Magazine

Properly maintained V-belt drives can be up to 97% efficient. Poorly operating belt drives can waste as much as 10% additional input power. Let’s consider a scenario that ignores motor losses and only considers losses in the belt drive. With electricity costs of seven cents per kWh, a rotor operating three shifts per day, five days per week, and requiring 50 horsepower from a belt-drive would consume over $16, 000 of power annually. An additional drop in efficiency of only 5% would result in increased costs of over $800 per year. In some industries, such belt drives may comprise more than 50% of the total drive population. This example clearly shows that big savings can be realized by properly maintaining them.

Read the entire article: Maintaining Belt Drives For Maximum Savings

by Bill Hillman CMRP

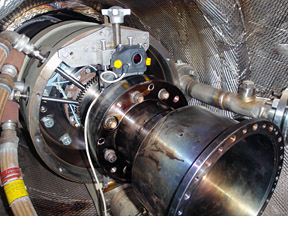

I recently completed a shaft alignment between a Solar Gas Turbine and a Gearbox on an offshore oil platform. The unique features only present on the ROTALIGN® ULTRA were key to this success. The repeatability we obtained was outstanding, less than 1 thou per measurement. Here are the reasons for our success:

1. We used the “Multipoint” measurement mode to perform an uncoupled measurement. Although the “Continuous Sweep” mode is a very fast and accurate measurement mode that takes thousands of points in a continuous sweep (one of our favorites), sometimes you don’t want to turn the shaft and measure at the same time. This was the case on this gas turbine, which was unique in that the shaft could change its radial position while you turned it. “Multipoint mode” takes not just 3 positions, but many measurement positions for superior accuracy.

2. The Standard Deviation function let us know we were taking accurate readings during the measurement. Standard Deviation was invaluable because sometimes we would find the shaft would not center itself after turning. Standard Deviation would reveal this while taking measurements, thus saving time and ensuring our accuracy.

3. “Multipoint” mode allowed us to adjust the number of measurement points taken per measurement position, up to 2048 points to be exact! Vibration is a fact of life out in the field. With this feature, vibration is negated. In fact, we only needed 128 points per measurement position and that took less than one second per measurement position.

by Daus Studenberg CRL

June 2010 · Uptime Magazine

When dial indicators, straight edges, and taper gauges were the only tools available for doing shaft-to-shaft alignment, machines were often left in a rough alignment condition. This happened because either too much time would need to be invested in order to obtain the required degree of precision or human error entered into the calculations. With the introduction of laser alignment tools, it has become a standard operating procedure to perform precision shaft-to-shaft alignment when machines are installed or reinstalled after a rebuild. Before the introduction of laser alignment tools, harmful soft foot conditions were often not addressed.

Read the entire article The Expected and the Unexpected – The Ever Increasing Benefits of Modern PdM Technologies

by Bill Hillman CMRP

Successfully persuading your management team about the importance of predictive maintenance requires a certain mindset, one that embraces the ideology that any failure in selling predictive maintenance lies within your selling techniques and not the management team. Success will simply depend on developing the proper selling methods. You are more likely to have success if you show management why they, not you, need predictive maintenance in the company. We have always heard that managers speak the language of dollars. This is true.

Attempt to avoid all technical reasons for justifying PDM and make good arguments based on savings and profitability. Reduced energy consumption, increased uptime, longer machine life, increased machine reliability, and improved products are just a few in a long list of items that will result from good PDM. However, just stating these items will not be very persuasive in your selling attempts. You must show how these benefits relate specifically to applications in your company and present dollar figures calculating the value added by the implementation of PDM technologies. Any data included with the dollar figures should be simple and easy to understand for a non-technical person. Trend plots, bar graphs, or pie charts are effective visual displays of such information. Your report should be concise but lengthy enough to convey relevant information. Brevity usually works best. If you don’t succeed on the first try, be persistent and improve your selling techniques. Remember, the fault lies in your methods and not with the management team. Luck is not a requirement for success. Only the proper arguments are required. Once the correct selling strategy is found, success is sure to follow.

by Bill Hillman CMRP

Several points should be checked prior to laser shaft alignment in order to avoid problems later and to achieve good results:

- Foundation: A solid, rigid foundation is essential for a successful alignment.

- Machine Mobility: It is advisable to set both machines with about 80 mils of shims underneath the feet in case one machine needs to be lowered. Also, jacking bolts provide a safer and more accurate way to make horizontal moves.

- Rigid Couplings: Must be loosened to achieve accurate readings.

- Coupling Play: This can be avoided by turning the shafts a few degrees before starting measurements and then taking readings in the same direction.

- Bearing Play: Check for excessive bearing play.

- Soft Foot: Check for and correct soft foot before performing a final alignment.

Soft foot can severely affect the operating condition of a machine, and will undoubtedly shorten its life expectancy. Here are a few simple tips to help avoid soft foot in your machines:

- Eliminate rust, dirt, and any other contamination from the contact surfaces of the machine feet, shims or foundation.

- Avoid using more than four shims at a time under the machine foot. More than three shims can cause a spring effect.

- Eliminate undue external forces on the machine frame such as those from connected piping, conduit, auxiliary supports, etc.

- Use high-quality, clean, and uniform shims when shimming is necessary.

by Ana Maria Delgado, CRL

Dowel pins in machinery have at least 3 functions. One function is to restrict relative movement and aid in the placement of two mating parts such as seen in bearing housing caps. Another function is to prevent improper orientation of components. Lastly, dowel pins are used to keep machine components in alignment. Our discussion will investigate this last function. Dowel pins are commonly seen on larger machinery. The dowels are usually placed in machine mounting feet or bearing housings. The intent is to prevent movement between these components and the base plate or foundation, thus keeping the machine train aligned. People rely on the dowel pins to maintain machine alignment and assume that if the dowel pins are in place the machine is aligned. During alignment checks, I have never found a doweled machine to meet the tolerances of a precision alignment. I recall one instance where a machine was precision aligned and after the alignment technician left the worksite the maintenance leader insisted on re-installing the dowel pins. Re-installing the dowel pins forced the machine back into a misaligned condition, so the previous efforts and expenses were a waste.

How should we approach the alignment of machines held in place with dowel pins? First, we should realize that proper machine mounting bolts when properly torqued are sufficient to hold machinery in place. The dowels should not be required if proper mounting fasteners and proper fastener techniques are used. When installing a machine with pre-existing dowels set the machine in place and re-install the dowels if you like. This will provide a starting point equivalent to a “rough alignment”. Now remove all the dowels except the machine component that you would designate as the stationary machine, remembering that this dowel may also have to be removed if, for some reason, the alignment process requires that this component needs to be moved. Proceed as with any other machine alignment. The component with the dowel left in place doesn’t really need the dowel and the dowel becomes only a point of reference.

Related article: Alternatives to using dowel pins in machine feet

by Bill Hillman CMRP

All laser shaft alignment systems should be able to take two sets of readings on well-built machines and find agreement at the coupling within 0.5 mils offset and 0.1 mils/inch angularity. It is important to always take two sets of readings immediately after setting up the brackets and compare the coupling results for repeatability. A good laser shaft system should have the capability of automatically recording the misalignment information for the user to compare for repeatability. If the readings do not repeat the problem may lie within the machines rather than in the bracketing or the shaft alignment tool itself.

Watch our Webinar: Laser Shaft Alignment: Repeatability & Accuracy Issues. Troubleshooting Your Readings.

by Ana Maria Delgado, CRL

Precision Alignment of electric motors coupled to pumps, compressors, gearboxes, blowers, etc.; contributes to savings in the consumption of electricity. Since all fossil power plant-generated electricity causes carbon emissions, the reduced electricity consumption also means LOWER RELATED CARBON EMISSION.

In 1984 the first pre-programmed Laser Coupling/Shaft Alignment tool was launched by our principals PRUEFTECHNIK Alignment. For already 25 years, our alignment tools are contributing to the GREEN movement. Not only does precision alignment contribute to going GREEN, but it also extends the life of Bearings, Mechanical Seals, and Couplings and extends the Mean-Time Between-Failure, thus saving money for parts and increasing production. All industries using pumps to transport hazardous liquids – and that means basically the entire chemical industry as well as refineries – have experienced leaking seals. Hazardous liquids contaminate the environment. Only well-aligned pumps guarantee that mechanical seals perform to perfection and that means avoidance of leakage, another area where Better Alignments help the GREEN movement. Every leaking seal or stuffing box in Water and Water Treatment plants is a waste of scarce resources. Only good alignment of motor-driven pumps will avoid leakage. Shaft/Coupling alignment contributes in more than one way towards great savings and a GREENER ENVIRONMENT.

by Dieter Seidenthal

For machinery installation, only the rotating shaft centerlines of different machines are aligned. Not the feet, not the coupling, not the shaft surfaces, not the machine housings, not the bearings; only the rotating shaft centerlines. It is important to understand that alignment refers to the positions of two centerlines of rotation or two rotational axes. Note that the shaft’s rotational centerline may be different than its machined centerline.

Shaft alignment means: Positioning two or more machines so that their rotational centerlines are colinear at the coupling point under operating conditions. Colinear means two lines that are positioned as if they were one line. Colinear, as used in alignment, means two or more centerlines of rotation with no offset or angularity between them.

The phrase “coupling point” in the definition of shaft alignment is an acknowledgment that vibration due to misalignment originates at the point of power transmission, the coupling. It does not mean that the couplings are being aligned. The shafts are being aligned, and the coupling center is just the measuring point.” At operating conditions” is an acknowledgment that machines often move after start-up due to wear, thermal growth, dynamic load shifts, or support structure shifts. Besides the above considerations, the term shaft alignment also implies that the bearings and shafts are free from preloads. In properly installed equipment, there are no forces or strains on the bearings and shafts, except those the designers intended. If the machine is installed with the frame distorted because of uneven or imperfect base plates, bent feet, pipe stresses, or whatever, then machine life will be shortened, often significantly. The only way to determine rotational centerlines is to rotate the equipment. There is no series of measurements that do not involve turning the shafts between readings that can be used to find the rotational centerline.

If you don’t turn the shafts…Any system that takes so-called alignment measurements without turning BOTH shafts is aligning surfaces, not centerlines of rotation. The results of any alignment efforts where one or both shafts are not turned are highly dependent upon the surface quality, rotor eccentricity, shaft straightness, and other surface defects. In short: “If you do not turn the shafts, you are not doing shaft alignment.”

Related Blog: The 12 Rights for Precision Shaft Alignment

by Ana Maria Delgado, CRL

In a sense, this post is about one, and only one topic: MONEY. If alignment can be improved, the machinery failure rate drops dramatically. Equipment failures are a major maintenance expense and have numerous incidental or associated costs. In fact, the cost of parts and labor to repair the machine can be one of the smaller costs. Lost production, contractual penalties, consequential damages, and liability for injury can all be much more expensive than the repair itself. If half of the alignments in your plant are done with a straight edge and the other half with dial indicators, our experience tells us that the average misalignment in the plant will be about 15 mils (offset and angular misalignment, where the angular misalignment is expressed in mils/10″). This misalignment will create an average power loss of 0.842% (please note that this is a very conservative figure: there is a high likelihood of this value being significantly higher.)

For machines operating 365 days a year, 24 hours a day, at an average cost of energy of $0.06 per Kilowatt-hour, the Total Cost of Lost Power (TCLP) for a small industrial plant running up to 150 small to medium-sized machines (average of 35 HP) can be determined to be:

TCLP = 150 machines × 35 HP/machine × 0.7457 Kw/HP × 365 days/year × 24 hours/day × 0.00842 × $0.06/KwHour = $17,325.70 per year.

With precision alignment, it is possible to achieve an average misalignment of just 2 mils. This misalignment creates an average power loss of 0.041%. Thus, the new TCLP will be:

TCLP = 150 machines × 35 HP/machine × 0.7457 Kw/HP × 365 days/year × 24 hours/day × 0.00041 × $0.06/KwHour = $843.65 per year.

Therefore, the reduction in Cost of Power is: $17,325.70 – 843.65 = $16,482.04.

These savings easily pay for a new laser alignment system in one year, without taking into consideration all the other attendant benefits from the reduction in misalignment, such as reduced vibration resulting in improved product quality, greater manufacturing output efficiency, and reduced wear and tear on the machines with the consequential reduction in labor, repair, and spare parts expenses. Add to this the reduction in unscheduled downtime and the savings become almost incalculable.

by Ana Maria Delgado, CRL

April 2010 · Wind Systems Magazine

The truer the shaft alignment, the lower the maintenance costs and longer the turbine life, but how can it be achieved? LUDECAwind has the answers. The world’s first electric power generating wind turbine was manufactured by Charles Brush in 1888, and it delivered 12 kW of power reliably for 20 years (Fig. 1). The battle to make wind energy economically viable has been going on ever since, and it must be fought on many fronts. One key element in the struggle for increased reliability and efficiency is achieving excellent shaft alignment of the wind turbine generator train. Is this an uphill battle for you?

by Ana Maria Delgado, CRL

October 2009 · IMPO Magazine

Unlike imbalance, misalignment does not produce forces that are similar in the radius of the machine. Vibration in one radial direction may be very different in amplitude when compared to vibration in another radial direction. This is one instance where amplitude readings are not only helpful in detecting a problem but also helpful in diagnosing a problem. Misalignment can result in a machine having high vertical vibration on one end and high horizontal vibration on the other with other radial readings remaining low. Imbalance is not likely to cause this amplitude pattern.

Read Vibration Due To Shaft Misalignment

by Ana Maria Delgado, CRL

February 2010 · Maintenance Technology Magazine

Going green is not something to be taken lightly. Not only is our livelihood at risk, but our very lives may also depend on how well we meet the challenges of living green. To cover all the benefits of going green would require multiple, book-length documents; therefore, we will limit this discussion to the green benefits of precision machine alignment. Precision alignment produces these types of benefits in four areas: energy savings, improved machine life, better products, and less pollution.

Read Go Lean and Green: Align The Machine

by Ana Maria Delgado, CRL

February 2010 · Pumps & Systems Magazine

Vertical pumps are designed to be “self-aligning” due to the rabbet fit between pump and driver, thus eliminating the need for precision shaft alignment. Notwithstanding these advantages, this article will focus on the need for the alignment of vertical pumps.

Read Are Your Vertical Pumps Throwing Money Down the Drain?.

by Ana Maria Delgado, CRL