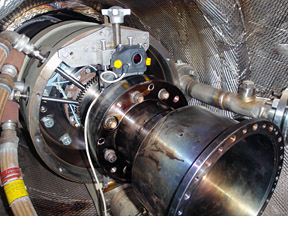

I recently completed a shaft alignment between a Solar Gas Turbine and a Gearbox on an offshore oil platform. The unique features only present on the ROTALIGN® ULTRA were key to this success. The repeatability we obtained was outstanding, less than 1 thou per measurement. Here are the reasons for our success:

1. We used the “Multipoint” measurement mode to perform an uncoupled measurement. Although the “Continuous Sweep” mode is a very fast and accurate measurement mode that takes thousands of points in a continuous sweep (one of our favorites), sometimes you don’t want to turn the shaft and measure at the same time. This was the case on this gas turbine, which was unique in that the shaft could change its radial position while you turned it. “Multipoint mode” takes not just 3 positions, but many measurement positions for superior accuracy.

2. The Standard Deviation function let us know we were taking accurate readings during the measurement. Standard Deviation was invaluable because sometimes we would find the shaft would not center itself after turning. Standard Deviation would reveal this while taking measurements, thus saving time and ensuring our accuracy.

3. “Multipoint” mode allowed us to adjust the number of measurement points taken per measurement position, up to 2048 points to be exact! Vibration is a fact of life out in the field. With this feature, vibration is negated. In fact, we only needed 128 points per measurement position and that took less than one second per measurement position.

Filed under:

Alignment by Daus Studenberg CRL