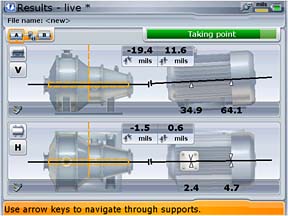

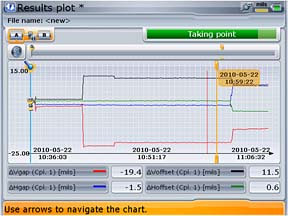

The biggest contribution one can make to lower the operating costs of rotating systems is to align them correctly using the real coupling target values. Target values recommended by manufacturers do not always reflect the real machine centerline movements due to thermal growth, pipe strain, and dynamic factors. The new ROTALIGN® ULTRA Live Trend, a short-term continuous monitoring application, helps to exactly determine the relative positional changes between coupled machines during start-up or shut-down. By applying these values, the machines are precisely aligned to reflect normal operating conditions. In addition, Live Trend allows you to establish a trend of the events that influenced such positional changes. With Live Trend, you can also monitor pipe growth and any other machine components over time.

- Lower energy costs through reduced power consumption

- Increased mechanical life of bearings, seals, shafts, and couplings

- Reduced bearing and coupling temperatures

- Minimized breaking or cracking of shafts

- Reduced vibration

- Reduced machine damage

Reliability starts with precision shaft alignment!

Filed under:

Alignment by Ana Maria Delgado, CRL