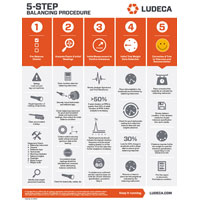

Just what does it take to be successful at balancing? Let’s start with some basics. First, you need to have an understanding of the balancing process, next nomenclature: is it unbalance, imbalance, out of balance, or what?

Use a consistent description and stick with it. Next, think about what the source of unbalance could be: is it uneven wear on parts? Voids within castings? Damage from impacting? Material buildup? Even though buildup is not usually a problem, when it begins to come off it rarely does so evenly thus creating an unbalance. In other words, unbalance is simply the uneven distribution of mass.

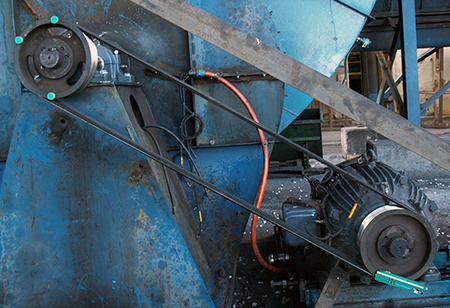

Simply review or collect data to ensure that the undesirable vibration is from unbalance and not some other issue such as a belt problem, misalignment, electrical issue, etc. Once you’ve determined that the vibration is indeed unbalanced you need to inspect the object to be balanced. If it is not clean, clean it. Look for damaged or broken parts. On belt-driven equipment inspect the belts as their frequency can be very close to running speed and can hinder the balance job. Make sure you have the proper tools for doing the balancing job, such as a balancing instrument capable of reading the vibration that is produced at running speed or what is commonly referred to as 1×or 1 times and capable of indicating the phase angle at 1×. This could involve utilizing an optical tachometer, laser tachometer, magnetic pickup or even a stroboscope. Some tachometers will require a piece of reflective tape on the shaft for the tachometer to read from and this might require stopping the machine if still in service.

Tip: I try to place the tape horizontally, or along the axis of the shaft, with the leading edge of the tape on the trailing edge of the keyway. This can be helpful if you ever have to return for another balancing job on the same machine. You need to determine if you will be adding or removing material in order to balance the rotating component. If removing material, how will you determine how much you’ve removed; if adding weight, you need to make sure the weight you are adding is of a material that is compatible with the service the machine is exposed to. If adding material “weights”, how will they be attached? With set screws? Bolts? Clamps? Welded on? All this should be considered. One last tip: if after two runs you’re not there or almost there yet, you might need to stop and examine your process to ensure no mistakes have been made.

Download LUDECA’s 5-Step Balancing Procedure.

by Gary James CRL

1. Collect the best data you can, using a high-quality ultrasonic data collector.

2. Consistent sensor placement must fundamentally be observed.

3. Identifying boundaries that impact data transmission is imperative.

Ultrasound is Shy… It Keeps Boundaries

Think of ultrasound as the quiet introvert. It prefers to stay in, and rarely mixes well with ultrasounds from other places. We call this “boundary behaviour” and it’s another characteristic that makes ultrasound such an attractive condition monitoring technology. Ultrasound signals remain isolated to their source, making it easy to pinpoint defects without interference from other elements of the machine.

Sensor Placement

Inspectors tempted to place their ultrasound sensor directly on the gearbox cover should reconsider. This common mistake affects data integrity. A gasket seals the cover plate to the gearbox housing. The specific acoustic impedance of the gasket material differs greatly from the cast metal of the gearbox. The change in materials a boundary barrier through which bashful ultrasound is reluctant to be passed. A better option is to place the sensor on a bolt head, which is directly connected to the gearbox housing. The result is crystal clear ultrasound signals for listening, trending, and condition assessment. HearMore: Click here to listen to Damaged Gearbox.

Special thanks to our partner Allan Rienstra from SDT Ultrasound Solutions for sharing his great knowledge with us!

by Allan Rienstra - SDT Ultrasound Solutions

With the proliferation of online monitoring systems utilizing permanently mounted sensors, users will need to beware of “direction sensitive” vibration and possible sudden unexpected failure due to insufficient data. The thought of insufficient data may seem incredible when thinking of constantly monitored equipment, but consider the all too common (IMHO) practice of uni-directional (one direction) monitoring of machine trains.

Many installations, due to initial cost, are mounting a single vibration sensor at each bearing. While this may be sufficient for most equipment trains, most of the time, it will certainly not be sufficient for all equipment trains all of the time. Although I don’t have hard data available, if I were to make a statement based on personal experience, and anecdotal evidence from other practitioners, my statement would be something like this: “80% of horizontal equipment could be pretty well monitored by sensors mounted at the horizontal radial position on each bearing.” I say pretty well monitored because I just can’t bring myself (as an analyst) to be completely satisfied without the vertical and axial data.

This setup would catch virtually all unbalance and roller bearing faults (excluding thrust bearings), some to most misalignment faults, and a sprinkling of others. I use the word “catch”, to mean it would give an indication of a developing problem. Accurate diagnosis of unbalance, misalignment, bent shaft, and even looseness in many cases (as well as a host of other possible faults) would require more data.

If the online vibration program manager takes these facts into account and governs the program accordingly, they should be pretty successful. If they add to the online program a “full battery” vibration survey, maybe semi-annually, just to catch the less common, but possibly very destructive defects that could develop undetected by the uni-directional monitoring, they would most likely be very successful.

What could be so destructive and yet be completely undetected by the uni-directional sensors? The Big R for one is Resonance. Resonance is often extremely directional. Consider a case history LUDECA co-published with one of our customers in the December 2012 Wastewater Processing magazine:

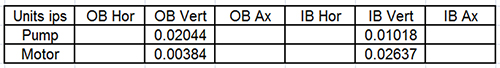

In the table below (Figure 1), the 1× amplitudes are displayed. I have hidden all but the vertical data, as though it were monitored only by vertical sensors.

Everything is wonderful right? Look at the motor outboard vertical, only 0.00384 inches per second—very impressive. Of course, at this point you are thinking “he is setting me up for something” and you are correct. Even though most anyone would love to have these amplitudes on virtually any machine, this particular machine was tearing itself apart with vibration!

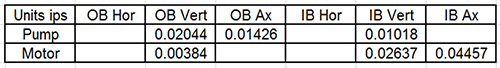

We will give the reader a little more data, just to help add emphasis to the directional nature of resonance. We will add the axial data to our table in Figure 2:

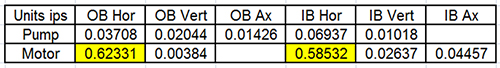

Still very, very good… so far. Now, look at Figure 3, with the addition of the horizontal data.

The motor outboard horizontal amplitude is 162 times the amplitude of the motor outboard vertical! What if the user had only vertically mounted sensors? What about vertical with the added information of axial? You may be thinking “if I had only horizontal sensors, I would have been ok”, and for sure you would have been better off than having only vertical. You would at least have known you had a problem, but you would not have known what that problem actually was. You would likely have assumed the vertical and axial are probably vibrating badly too.

Hopefully, you would have verified the vibration in the other directions. As it was, the user had data from all directions and a simple glance told the analyst with a high degree of confidence what the problem was. Resonance is almost alone in creating that kind of directional disparity.

To reiterate, the online vibration program manager should be successful if they take into account the fact of limited data and supplement the online program with a “full battery” vibration survey at a cost-effective interval, just to catch the less common, but possibly very destructive defects that could be developing undetected by uni-directional monitoring.

by Mike Fitch CRL

While the person in charge of collecting vibration data is actually collecting the data, they should watch the data “live” for unusually high amplitudes or discontinuities in the data. This will not increase the data collection time, and if any of these issues are detected, the person can evaluate whether or not the data is “good” or not; if not, the data can be recollected, or if it is “good” then additional data may need to be collected to ensure that proper analysis can be performed on the equipment. Field notes can be made about the machine’s condition and its status.

If the machine condition is determined to require attention, the analyst might need to contact someone at the facility. Remember that sudden increases or decreases are usually a sign of machine problems. Looking at or analyzing the data in the field can give the analyst a good idea of what issues need to be analyzed, thereby reducing the time to analyze data in the office. If not analyzing the data on the spot, one can at least make notes to aid in later analysis.

by Gary James CRL

♫ And it’s too late baby now, it’s too late; though we really did try to make it. Something inside has died and I can’t hide and I just can’t fake it…♫

So go some of the lines of the old Carole King hit from 1971. Unfortunately, that pretty well sums up the situation for those sad contemporary souls who have computer crashes but didn’t have their databases backed up on a regular, frequent basis. The part about “I just can’t fake it” is especially true after “Something inside has died” (that is, inside of the computer). When you lose your database or databases, there’s just no faking it.

If you are like most, you get a sick feeling inside just thinking about it, and you resolve to get started soon by making a habit of backing it all up. Procrastinate no longer, friend. Get help from your I.T. department, or if you don’t have one, there are numerous players now, that for a small fee, will back up and protect your important data, either locally or in the cloud.

Don’t wait until you are singing the old Carole King song, “It’s Too Late”. Go ahead and protect yourself.

by Trent Phillips CRL CMRP - Novelis

How many facilities only collect vibration data when it doesn’t interfere with other activities? So often collecting and analyzing data is only one part of a given person’s responsibilities and workloads dictate that the collection and/or analysis take a back seat. When this happens, machine problems are not detected and therefore not reported for corrective action to be taken. If a machine then fails management has all the right to ask why the problem was not found and reported, even if management itself is the reason the data was not collected or analyzed! Vibration data collected should also be analyzed in a timely manner (within two business days of collection) to allow for proper scheduling of any needed repairs; of course, if problems are detected while collecting data that are believed to be severe enough to merit immediate attention, then they should be reported immediately to the facility. Many analysts do not know how long it will take to approve, plan, order parts, kit out, and schedule the resources to execute the repair work. Therefore, one must collect, analyze, and report the data as soon as possible. Generally, you may find several problems in most facilities; however, if you hand in 20 or 30 reports to the Reliability contact, they can quickly be overloaded. I would collate and deliver all the necessary reports but would focus on the top 5 priority problems first, based on safety, criticality, severity, and production demand.

by Trent Phillips CRL CMRP - Novelis

Condition Monitoring Expert Tip #9 by Mobius Institute

No, sadly, that may not be correct. If the spectrum (and phase readings) indicate misalignment, then the machine will be misaligned. But if there is no indication of misalignment, the machine may still be misaligned. I know that may not make sense, but unfortunately, it is true.

A number of experiments have been performed where real machines were misaligned and the vibration pattern did not change. The vibration pattern depended upon the type of coupling and other conditions, but the bottom line is that the only way you can be sure that the machine is precision aligned is to precision align the machine with a laser alignment tool.

We appreciate Mobius Institute for allowing us to share this tip with you!

by Ana Maria Delgado, CRL

Using ultrasound to locate compressed gas leaks is relatively easy, but occasionally it can present some challenges. The reason ultrasound is so successful is that it is a high frequency, a short-wavelength signal that does not like to penetrate 2nd mediums. While performing compressed gas leak inspections, keep in mind that strong ultrasonic signals can bounce off most materials leading to false indications.

To overcome this challenge, turn your ultrasonic detector 180° and see if the signal is stronger coming from that direction.

Download Find-and-Fix Leaks Procedure

by Paul Klimuc CRL - SDT Ultrasound Solutions

Condition Monitoring Expert Tip #7 by Mobius Institute

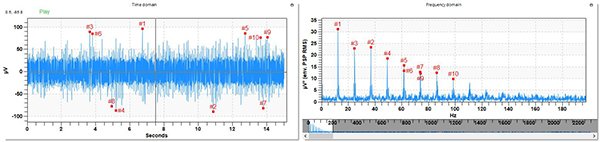

Spectrum analysis provides a great deal of information about the health of rotating machinery. But you should consider the spectrum as a summary of the vibration within the machine.

The Fast Fourier Transform takes the time waveform and computes how much of each frequency is present and displays that as a line in the spectrum (grossly summarized, but that is basically the case). Therefore, if the vibration from the machine is generated by smooth periodic motion, then the spectrum provides a very good representation of what is happening inside the machine. But as damaged gears mesh together, and rolling elements pass over damaged areas on the raceway of the bearing, and as the pump vanes push through the fluid causing turbulence or cavitation, the vibration generated is not smooth and periodic. And there are a lot of other fault conditions that likewise do not generate smooth and periodic vibration. Thus, the only way to really understand what is happening inside the machine is to study the time waveform.

The time waveform is a record of exactly what happened from moment to moment as the shaft turns, the gears mesh, the vanes pass through fluid, and the rolling elements roll around the bearing. Each minute change that results from impacts, rubs, scrapes, rattles, surges, and so much more is recorded in the time waveform and then summarized in the spectrum. Therefore, it is critical to record the time waveform correctly and analyze it when you have any suspicion that a fault condition exists.

Special thanks to Mobius Institute for letting us share this condition monitoring expert tip with you!

by Ana Maria Delgado, CRL

Belt alignment is extremely important, and we recommend you do it with a good laser alignment system such as the Easy-Laser XT190 or the DotLine Laser system.

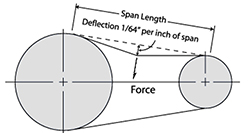

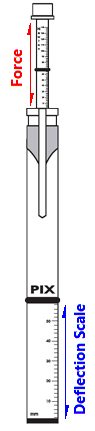

But, once the pulley alignment is done, equally important is to set the belts to the proper tension. Typically, the correct tension is one that allows the belt to be deflected on its tight side by a specified amount of force to an amount of 1/64th inch per inch of span length. The span length is the distance between the nearest points of contact of the belts on their sheaves. If this distance is not known, you can use the center distance between the pulleys; that’ll be close enough.

To do this, you use a spring tension gauge, which is a device that measures the amount of force that you apply to something when you push against it or pull on it.

So, say the span length of a given belt drive is 36 inches. You should deflect the belt (in a group of belts, usually the center one, but measure the two outside ones as well) by 36/64″, (or 9/16″) which is 1/64″ of deflection for every inch of span length, and measure how many pounds or newtons of force it takes to do that. This force should not be less (too loose) or more (too tight) than what the manufacturer of the belts recommends for that drive or for that set of belts. Also, you perform this test by pressing down with your gauge upon the belts in the middle of their span length on the “tight side” of the belts. The tight side of the belts is the side that is stretched as the drive turns and the driver pulley applies rotational force to the driven pulley. The return side is the slack side of the belts.

The recommended belt tension deflection forces are usually supplied in a table that takes into account the size, length, and type of belts, the number of belts in the drive, the anticipated application loads and drive ratios of the sheaves. Move the driver until the recommended force specification is met for the desired deflection, being careful not to mess up the sheave alignment while doing so!

Download 5-Step Sheave/Pulley Alignment Procedure

by Alan Luedeking CRL CMRP

Condition Monitoring Expert Tip #10 by Mobius Institute

No, sadly, that is not right. Unless the person has been properly trained, unless the company has specified precision alignment tolerances, and unless the training is followed and the tolerances are achieved, then you are not performing precision alignment.

We see this as a very common problem. Laser alignment systems can achieve terrific results. And a precision-aligned machine is far more reliable than a machine that has been “roughly” aligned with an alignment system, and far superior to a machine aligned with a straight edge. But if your maintenance technicians do not appreciate why that last shim should be installed, and why the motor must be moved such a small amount to the left or right, then those corrections will not be made – and yes, it does matter.

Research by Tedric A. Harris, in the book “Rolling Element Bearing Analysis” (John Wiley & Sons), showed that just 5 minutes (5/60 of a degree) of angular misalignment can reduce the life of a bearing by half. Yes, precision matters!

by Yolanda Lopez

- Make sure the surfaces of the vertical posts are clean.

- Improve the contact between the vertical post and the crossbar by applying a light coat of Vaseline or grease to the contact surface of the vertical post.

- The temperature probe should always be placed on or as close as possible to the inner race or ID of the workpiece being heated.

- When possible make sure a second probe is placed on the outer race or OD of the workpiece being heated to also track the temperature of the OD, in line with the ID probe.

- For the most efficient heating, always use the largest possible crossbar that will fit through the ID of the workpiece being heated. Stacking of multiple crossbars is permissible.

- It is not a requirement that the workpiece must touch the crossbar(s). Just so long as the bar goes through the bore (ID) someplace.

- Most important of all is that the workpiece being heated always be automatically demagnetized. Any induction heater that does not do this automatically COSTS you money instead of saving it.

by Bernd Seidenthal CRL

Condition Monitoring Expert Tip #5 by Mobius Institute

Now, this is a tricky question to answer… We have a few contenders: high-frequency vibration analysis, regular vibration analysis, ultrasound, oil analysis, wear particle analysis, and infrared analysis. Let’s start by ruling a few of them out.

Infrared analysis is used to detect heat in a bearing, which is a late-stage fault condition, so that’s not your best option. Regular oil analysis can detect the presence of the wear metals within the bearing, but wear particle analysis is a better tool for that. Regular vibration analysis (i.e. velocity spectra) provides very clear indications of bearing faults, however, the high-frequency detection techniques provide an earlier warning. That leaves high-frequency vibration analysis, ultrasound, and wear particle analysis.

Ultrasound is the easiest to use. Push the probe against the bearing and listen carefully and you will hear if the bearing is in distress. (You can also record and analyze a waveform, but now you may as well be performing vibration analysis). Many would argue that high-frequency vibration analysis (such as enveloping, PeakVue, shock pulse, and others) provides a clearer indication of the nature and the severity of the fault. But it does require more training and potentially a more expensive system to perform the collection and analysis.

And that leaves wear particle analysis. Let’s just say that if you own critical gearboxes, you absolutely must perform wear particle analysis. Performed correctly, you will detect the first signs of wear, and complex gearboxes provide a greater challenge for the vibration analyst and the ultrasound tools.

Although I haven’t really answered the question, I am hoping to have put you in a position to make the right decision for your situation.

Thank you Mobius Institute for this valuable tip!

by Yolanda Lopez

Belts are a critical part of the design and function of belt-driven equipment. The majority of belts never reach their intended design life due to improper selection, storage, and installation. Unfortunately, this results in compromised equipment operation, lost capacity, and increased costs. Do not condemn your equipment to death through improper belt installation practices. Below are some guidelines to help your facility ensure belt-driven equipment reliability:

- Follow all site-specific safety procedures.

- The same basic installation steps are required for both synchronous and V-belts.

- Loosen motor mounting bolts or adjustment screws.

- Move the motor until the belt to be replaced is slack and can be removed easily without prying or any other means of force. Prying off a belt or chain can damage a sheave or sprocket and increase the risk of injury. Never use a screwdriver to remove belts, because this may damage belt cords, sheaves, and sprockets.

- After removal, inspect the old belt for unusual wear that may indicate problems with design or maintenance issues.

- Visually inspect and replace sheaves or sprockets that have excessive wear, nicks, rust, pits, or are bent. Grooves that appear “shiny” or polished could indicate heavy wear and should not be ignored. Never sand or scrape groves. Doing so will insert points of wear leading to a premature belt or sheave failure.

- Sheave gauges should be used to measure for excessive wear and determine if sheave replacement is necessary. Total wear should not exceed 1/32 in or 0.8 mm.

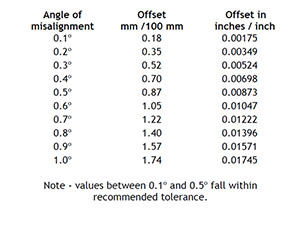

- Sheaves and sprockets should be checked for proper alignment. A laser alignment tool is the recommended means. Most major belt manufacturers recommend a nominal tolerance of 0.5 degrees. However, better alignment tolerances should be achieved if possible. The table below can be used to determine proper alignment.

For maximum resolution, always mount the laser alignment tool on the smaller sheave and the targets on the larger sheave. Ensure that the alignment tool being used can indicate misalignment in all three degrees of freedom (axial offset, horizontal angularity, and twist angle).

For maximum resolution, always mount the laser alignment tool on the smaller sheave and the targets on the larger sheave. Ensure that the alignment tool being used can indicate misalignment in all three degrees of freedom (axial offset, horizontal angularity, and twist angle).

Note 1: Check and correct any run-out conditions prior to belt installation. Tighten bolts in the proper sequence to prevent axial run-out.

Replace all belts on multiple belt drives with new belts from the same manufacturer. Never replace a single belt or a portion of a multiple belt drive. Mixing old and new belts will create unevenly shared loading and lead to premature belt failure and/or sheave wear.

- When installing the new belt, ensure that enough clearance is available to slip the new belt(s) over the sheave or sprocket. Never pry or use force to install the belt(s). Never use a screwdriver to roll belts into position, because this may damage belt cords, sheaves, and sprockets.

- Adjust the motor base until the belts are tight. The motor should be checked for soft foot conditions using a feeler gauge or other suitable means and corrections made if required. No reading of soft foot should be greater than 0.002 inches or 0.05 mm.

- Use a tension gauge or sonic tension meter until the correct tension is measured according to specifications.

- Rotate the belt drive by hand a few revolutions and re-check and adjust belt tension as necessary.

- Re-check the sheave or sprocket alignment and re-adjust if necessary.

- Secure motor mounting bolts to the correct torque specifications.

- Replace equipment guards and follow any other site-specific safety requirements to return the equipment to operation.

- Upon equipment startup, listen and visually inspect for any unusual vibration, noise, or heat. Other corrective actions may be required (lubrication, tension adjustment, etc.) to ensure equipment is ready for proper operation.

Note 2: Contact the belt manufacturer and provide the drive information to receive the most accurate tension information for the required operating loads. Belt tension charts may specify more tension than is required by the application. The proper tension for the belt is the minimum tension required to prevent the belt from slipping at maximum load. A good guideline in the absence of any other information is to use a spring scale and press down on the belt in the approximate center of its span (on the tight side), to deflect the belt 1/64″ per inch of span length and observe the force required to do so. If you are not sure of the belt span length you may also use the center-to-center distance of the pulleys, which will be similar. Tension the belts until the force required for this deflection equals the belt manufacturer’s maximum recommended force values for the specific belts you are using.

Note 3: Belts should not squeal on startup when adjusted to proper tension. This can be an indication that the drive is not proper for the application.

Note 4: A run-in procedure may be required for V-belt drives or other installations to ensure optimal belt life and equipment reliability. It is recommended to check and adjust belt tension under full load after 20 minutes, 24 hours, and 48 hours of operation to properly seat the belts in the sheave grooves. Consult belt manufacturer and engineering specifications to determine if a run-in period is required and the length of time.

by Trent Phillips CRL CMRP - Novelis

Unfortunately, proper storage of belts is often overlooked. I visit a lot of plants and almost always see equipment belts improperly stored to the detriment of optimal reliability. Ensuring that the belts used in your equipment are properly stored will result in:

- Fewer failures upon startup

- Longer belt service life

- Better equipment performance

- Improved safety

- Preservation of belt warranty coverage

Below are some belt storage tips to help ensure that your equipment functions as healthily and long as possible:

- Belts should be stored in a cool and dry environment with no direct sunlight. Storage temperature should be below 85°F/29.5°C with a relative humidity no higher than 70%. Belt performance is reduced by 50% for every 15°F / 9.5°C above 115°F / 46°C.

- Do not store belts in areas exposed to:

- Airborne chemicals

- Heat sources

- Direct sunlight

- Airflow from heat sources

- Transformers, refrigerators, motors, or other sources that create ozone

- It is not recommended to store belts on the floor. If floor storage is required, the belts should be stored in a protective container and never exposed to foot traffic.

- Never twist, bend or crimp belts during storage and handling. Doing so will damage them.

- Do not hang belts from pegs as they will distort over time. Do not store belts under any state of tension.

- V-belts may be stored by hanging on a wall rack only if hung on a saddle with a diameter at least as large as the minimum diameter sheave recommended for the belt cross-section. If coiling a V-belt for storage, consult the supplier for limits. It is always best to store belts flat on a shelf.

- Store belts in the original box. Stacking of belts on top of each other should be limited. Ensure that the belts on the bottom are not damaged by the weight of the belts on top.

by Trent Phillips CRL CMRP - Novelis

As Published by Maintenance Technology Magazine September 2017 issue

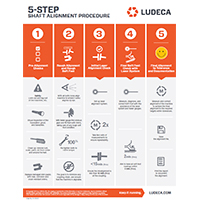

If greater reliability and uptime are of any concern to you, then precision maintenance is a key component in achieving it. This means having clear and simple, yet meaningful, procedures in place for the different tasks involved. Two such tasks are precision alignment and balancing. LUDECA’s 5-Step Procedures will help guide your facility and maintenance staff to achieving precision maintenance.

Get your own copy of these 5-Step Procedures:

Download 5-Step Shaft Alignment Procedure

Download 5-Step Balancing Procedure

Why is precision maintenance so important? The reasons are clear:

- Safety

The alignment and balancing procedures lay out the basic steps required to align and balance machines safely, reducing the risk of injury and increasing the likelihood of a quality outcome. Checklists simplify the workflow and serve to remind employees of the processes required to consistently and safely perform the precision maintenance task. - Reliability

Well-aligned and balanced machines run more reliably, with a greatly reduced probability of failure. This allows for better maintenance planning, greatly reduced repair and maintenance expenses, increased uptime, and more profits. - Efficiency

A good alignment procedure ensures that machines are aligned to the proper tolerances for the running condition of the machines, taking into account such things as thermal growth and anticipated positional changes. This ensures that the greatest efficiency is achieved in your running machinery, prolonging their health and reducing power consumption. Studies have shown that well-aligned machines result in a 3% to 10% reduction in power consumption. Noise and heat generation are reduced, producing a safer work environment. - Production Quality

Good alignment and balancing result in better product quality since vibration is minimized, resulting in more uniform and higher product quality. Unexpected breakdowns in production machinery may lead to costly waste from scrappage and high restart costs for the production line. - Training & Procedural Consistency

Once implemented, a procedure ensures all employees involved in the activity face clear and consistent expectations and processes, leading to a better understanding between all staff in the facility. Training expenses can be reduced since often only refresher training is required to update understanding of the technology utilized as updates are rolled out. Records should be kept that document employee training.

The next step in precision maintenance and reliability is the Implementation of formal specifications that detail every step in a task from safety to activity process to documentation, to ensure that anyone involved can follow the procedures and guidelines without confusion, and reach the desired outcome for all machinery types in the plant. Such specifications typically take from two to three months to develop and a further two to three months to roll out and fully implement. LUDECA has written a number of these specifications for customers worldwide. Let us help you as well.

by Alan Luedeking CRL CMRP

Condition Monitoring Expert Tip #3 by Mobius Institute

This tip is sponsored by IMVAC (International Machine Vibration Analysis Conference)

How do you decide which assets should be monitored? How do you decide whether you can justify the use of more than one technology? Criticality analysis provides a means to prioritize which assets will be monitored and how much effort will be put into collecting data and performing the analysis.

Criticality analysis considers several factors. It will consider the consequences of failure, for example, health and safety, harm to the environment, downtime and production losses, availability of spares, cost of spares, etc. It will also consider the reliability of the asset; how likely is it to develop a fault condition. And it should also consider the detectability of the fault conditions. Therefore, an unreliable asset where failure would lead to dire consequences and where we currently cannot detect the onset of failure absolutely requires condition monitoring and can justify multiple technologies. At the other extreme, a reliable asset’s minimal consequences of failure may not require any condition monitoring; we may employ “run to failure”.

Criticality analysis enables you to make the best use of your limited resources.

Special thanks to Mobius Institute for allowing us to share this condition monitoring expert tip with you!

by Yolanda Lopez

It seems that every maintenance department has a hard time installing bearings because of the problems inherent in conventional heating methods.

Applying care, good technique and heating methods are better. Over 90% of rotating equipment has defects at startup that can result in equipment failure.

One reason bearing installation is often a herculean task is not using proper heating methods. Excessive heat applied to the bearing during installation can introduce defects that lead to premature equipment failure. Instead, heating a bearing on an induction heater, automatically demagnetizing it, and then slipping it on the shaft free of stresses is the way it should be done. The results of overheating a bearing are increased maintenance costs, increased safety risks, and more equipment downtime.

Proper heating methods and best practices should be applied to correctly install bearings. Induction heaters such as SURETHERM can help eliminate induced bearing defects due to poor fitting and improper mounting techniques. Induction bearing heaters provide increased safety, and increased efficiency and reduce the risk of bearing contamination and damage that can result from using brute strength, oil baths, blowtorches, or other improper methods of heating bearings for proper installation.

Here are some conventional methods that are used in Industry and why they are not the way to install bearings:

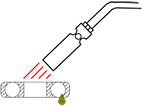

Heating a Bearing with a Blowtorch

– No temperature control

– No temperature control

– Risk of overheating

– Grease leaks out of the bearing

– Tension in material

Heating a Bearing using a Hot Plate

– No temperature control

– No temperature control

– Risk of overheating

– Grease leaks out of the bearing

– Tension in material

– Dangerous (plate stays hot)

Heating a Bearing in an Oil Bath

– Slow heating process

– Slow heating process

– New grease cooks off the bearing

– Dangerous (hot oil)

– Environmentally unfriendly

Heating a Bearing in an Oven

– Slow heating process

– Slow heating process

– High energy consumption

– Grease leaks out of the bearing

by Bernd Seidenthal CRL

Condition Monitoring Expert Tip #2 by Mobius Institute

This tip is sponsored by IMVAC (International Machine Vibration Analysis Conference)

How do you decide how often measurements should be taken?

Regardless of the condition monitoring technology, you must decide how often measurements will be taken. At one extreme, it could be a permanent monitoring system that takes measurements every split second of every day. On the other extreme, it may be infrared analysis that is performed once a year. But how do you make that decision?

The most common answer we receive is that it is based on the criticality of the equipment. More frequent measurements are taken on the more critical equipment. The next most common answer is that it is based on reliability. If you have been monitoring a machine with vibration analysis every 30 days and have not detected a fault for a year you may decide to test it every 60 days, or 90 days. Now, it is true that you have to decide how best to use your precious time. But the one factor often forgotten is the “PF interval”.

The PF interval, also known as the “lead time to failure”, is the time between when you can detect the fault condition and when the equipment will have “functionally failed” – i.e. it can no longer be used. If we use the right technologies with the correct settings and we take frequent measurements, then we will get the earliest warning, and therefore we have the greatest lead time to act. However, if the PF interval is short, then it is possible that if you have extended the measurement period to 90 days, the equipment may develop a fault and fail before you take the next measurement.

There is a lot more that could be said on this topic but suffice to say that it is essential that you understand the PF interval and continue to monitor equipment so that you take at least two measurements between the time the fault is detectable and when the asset will have functionally failed.

Special thanks to Mobius Institute for allowing us to share this condition monitoring expert tip with you!

by Yolanda Lopez

Guest Post by Bob Dunn from I&E Central, Inc.

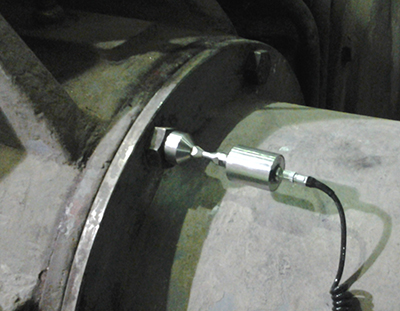

A customer was having difficulty balancing the rotor shown above. They had made multiple corrections, some contradictory, and were worse than when they started. In that this is on a shop stand and under controlled conditions, something was not right. Looking at the photo, I saw a couple of likely issues.

- The shaft is pretty reflective itself, it is doubtful that they were getting a good or consistent phase reading. I recommended they put a ring of black tape on the shaft, with the reflective tape on the black.

- The tach sensor is pointing at the shaft at about a 90-degree angle. Optical sensors and reflective tape works better if the sensor is aimed at an angle – 30 degrees or so.

- The tach sensor is pretty close to the rotor. In this case, it is not too close, but you can be too close. A sensor like this will work from several feet away, if you are having problems, try moving the speed sensor further away.

The customer applied the tape and adjusted the tach position. The rotor was balanced in a single run.

by Yolanda Lopez