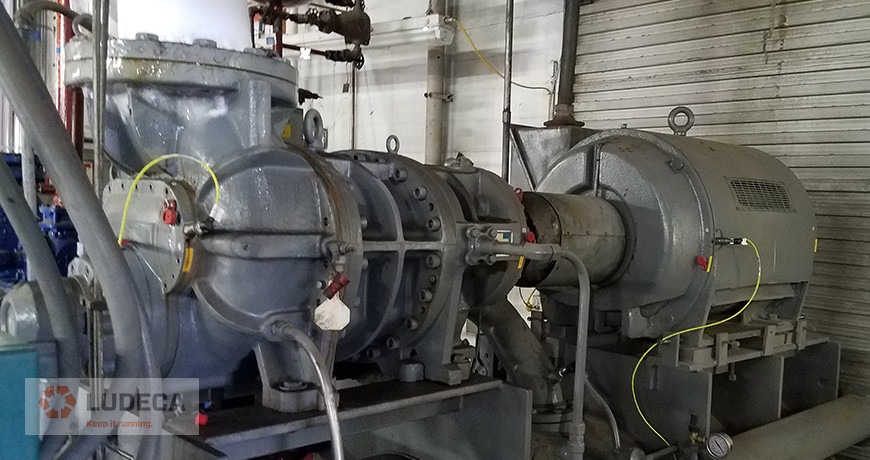

Reliability groups are often expected to collect data on critical assets in a consistent manner to ensure the asset’s health is monitored efficiently, and to maximize the life of that equipment. Doing this task manually may pose a safety or health risk to the personnel responsible for collecting the data. One of the solutions is to install permanently mounted sensors and wire them to a termination/switch box in a safe location.

It is important to note that there are several ways to permanently mount sensors to an asset, but the most common are:

Adhesive Mount

As the name says, this process entails utilizing a strong epoxy-like adhesive that creates a sturdy bond between the sensor and the asset. It is imperative that the two surfaces be thoroughly stripped of any paint and/or corrosion using a steel wire brush. This should be done to remove any surface imperfections that can compromise the integrity of the bond between the sensor and the asset, as well as remove signal dampening layers between the sensor and the machine.

Drilling and Tapping Mount

This process entails physically drilling a small pilot hole into the casing of the asset and then tapping the hole to match the thread of the stud included with the chosen sensor. This method is one of the preferred methods in the industry as it ensures a perfectly solid mount between the sensor and the asset.

Switch Box Vibration Data Collection

For either of the above methods, cabling must be routed to provide communication. It is of the utmost importance to route the cable through suitable conduits so that it is protected from harsh temperatures or chemical exposure that can potentially cause damage. Utilizing a label machine to identify each cable will ensure that the final wiring in the termination/switch box is accomplished properly and easily. Once the physical installation of the permanently mounted sensors and wiring is completed, the reliability technician that oversees the Condition Monitoring program can safely and efficiently collect data with the help of a capable data collector such as the BETAVIB’s VibWorks system. This will greatly improve the uptime of a facility’s assets and help maintain world-class reliability while maximizing the safety of its employees.

The importance of proper sensor installation when performing vibration analysis

Filed under:

Condition Monitoring, Vibration Analysis by Mario Rostran CRL