It is important to ensure that the top cover mounting surface, machine sole plates and rails, and main bearing “landings” of a compressor frame are installed as flat as possible. This ensures that the main bearing bores and internal components remain undistorted and aligned as per their factory specifications.

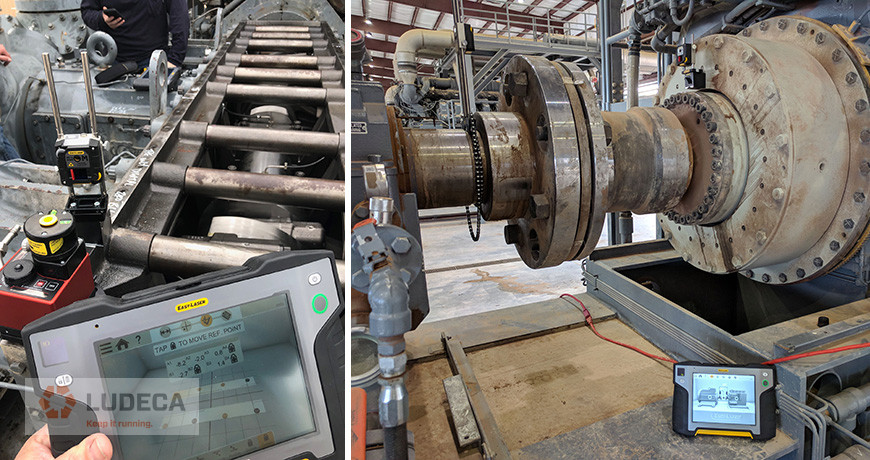

Ariel Compressors have a strict tolerance for the top rail alignment, and their ER-82 document discusses this in detail. Essentially, if the top rails are flat, the main bores will be as well, and provide a proper run condition for the crankshaft and bearings. There are many ways to perform a flatness check so long as the equipment used meets the Ariel guideline for accuracy. Some people have chosen an inclinometer-based system but systems like the Easy-Laser XT770G add a new dynamic in versatility. When checking a large frame like an Ariel KBB the XT770G gives the user consistent, reproducible measurements they can trust to make critical adjustments. By looking at the elevation of individual points, instead of the rise-over-run between them, the actual repair is made much easier.

The initial setup of the XT770G for a top rail measurement is simple. Because the Laser Transmitter is on a magnetic tilt table, the system can be put anywhere within line-of-sight for the rails to be measured— even on the rails themselves. Either a plate or a tripod may be used to position the laser. Before placing the sensor on the rail via magnet, you want to make sure the rails are clean and free of debris or excess oil. Once the rails have been cleaned the XT770G is bucked-in, to establish a plane that is reasonably parallel to the surface of the compressor. The system is now ready to take measurements for the required points. The number of points is determined by Ariel, based on the frame model.

Once set up, measurements with the XT770G take less than 5 minutes on a KBB frame or other large scale compressors, due to the freedom of a powerful Bluetooth connection. With the measurement data recorded, adjustments can be made by viewing the information in the rugged XT11 computer or the free iOS and Android applications. Several options are available for referencing the data, such as an All Points Negative, All Points Positive, Best Fit Around Zero, or even Custom Reference Points. These numbers can be plugged into the ER-82 spreadsheet. Reporting may also be done in the field through the USB option, or sent directly to an email address using the Wi-Fi embedded in the XT11 computer. The PDF report is ready to be imported into any work flow management software, keeping all measurements easily documented and ready to archive.

The Easy-Laser XT770G is a true commissioning focused alignment system that is capable of shaft alignment, ER-82 flatness, base twist, belt alignment and simple vibration.

Filed under:

Articles and Case Studies by Diana Pereda