Cardan Alignment can be done without removing the bracket when the following requirements are met:

- There is enough room to rotate lasers and the shaft at least 40 degrees.

- A laser shaft alignment system such as the EASY-LASER XT660 or XT770 is available.

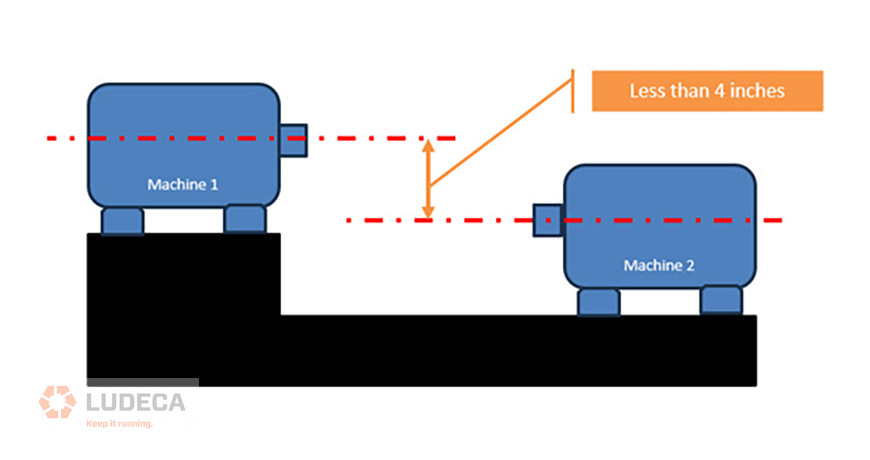

- The offset between machine shaft centerlines does not exceed 4 inches as shown in Figure 1 below.

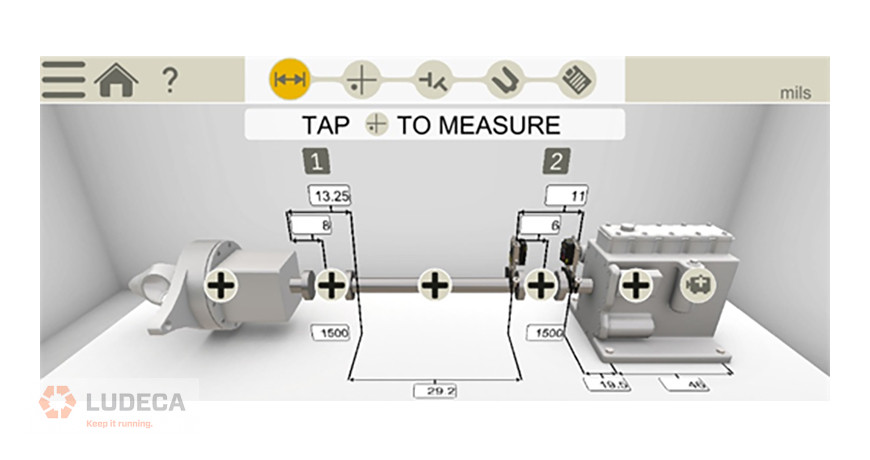

Using either of the recommended laser alignment systems, select machine train alignment and configure the machine train so as to make the cardan shaft the middle machine. Now measure the misalignment across the left-hand U-joint (Coupling 1) and then the right-hand U-joint (Coupling 2). See Figure 2 below.

Machines with a cardan shaft have a predetermined offset between them. Therefore, we only need to make sure that the two machines are parallel to each other by eliminating any angularity between them.

Correcting the angle of the movable machine can be done by making the position value of the front foot and rear foot of the movable machine the same with respect to the stationary machine.

Click here for additional information or to download the step-by-step procedure!

A Successful Cardan Shaft Alignment on a Boat using Multipoint Measurement

Filed under:

Alignment by Carlos Bienes CRL