Rotating equipment alignment may seem like a small detail, but it’s actually the foundation of a smooth-running operation. It all starts with ensuring that the feet of the equipment are flat and coplanar and that the baseplate they’re mounted to is also level and coplanar. Standards like ANSI/ASA Alignment S2.75-2017 have set strict guidelines for baseplate flatness (baseplate must be level to <10 mils/ft, coplanar to <2 mils and each foot must be flat to <5mils). But even with proper manufacturing, installation errors can occur.

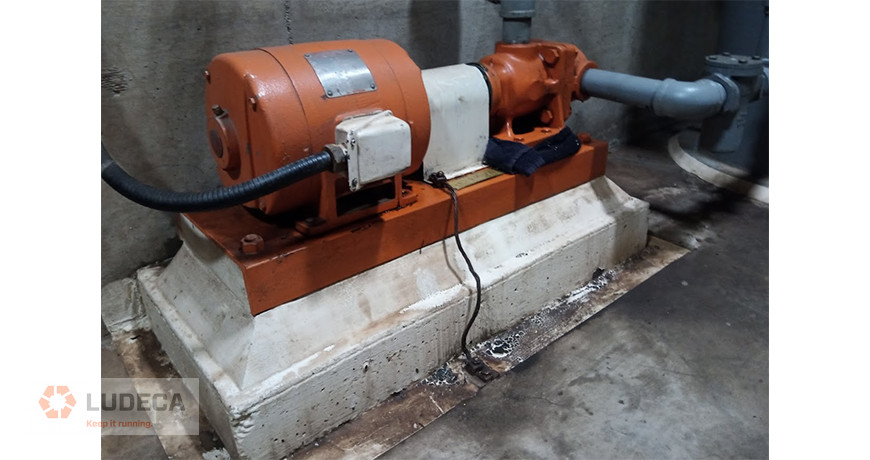

Picture this: a baseplate that was manufactured to be perfectly flat and coplanar, but due to poor installation practices, the baseplate is now twisted and deformed, causing soft foot issues that need to be corrected before alignment can even begin. This could have been avoided if the baseplate had been measured for flatness, and levelness after installation and properly grouted. The differences between an improper and proper installation are quite apparent as shown in the figures below:

In the past, this required a separate crew or contractor to perform optical and laser tracker measurements. But now, with the Easy-Laser XT770G shaft alignment system, the complete rotating equipment alignment commissioning package, it’s easy for the same installation crew to perform flatness and level measurements prior to alignment. The measurements can be taken, corrected and documented using the same computer that will be used for the shaft alignment task, making the process more efficient and accurate than ever before.

Download our 5 Element Machine Installation Infographic to help you outline 5 important elements of machine installation including Foundation, Anchoring, Isolation, Baseplate Level, and Flat plus Alignment.

Filed under:

Alignment by Daus Studenberg CRL