In vertically oriented shaft alignment, the objective is to make sure that the rotating axes of both shafts are lined up at the coupling during operating conditions. There are sometimes extra constraints such as plumb, which need to be taken into consideration. In this application, we have a typical vertical water condenser pump in which the pump housing has already been grouted into place.

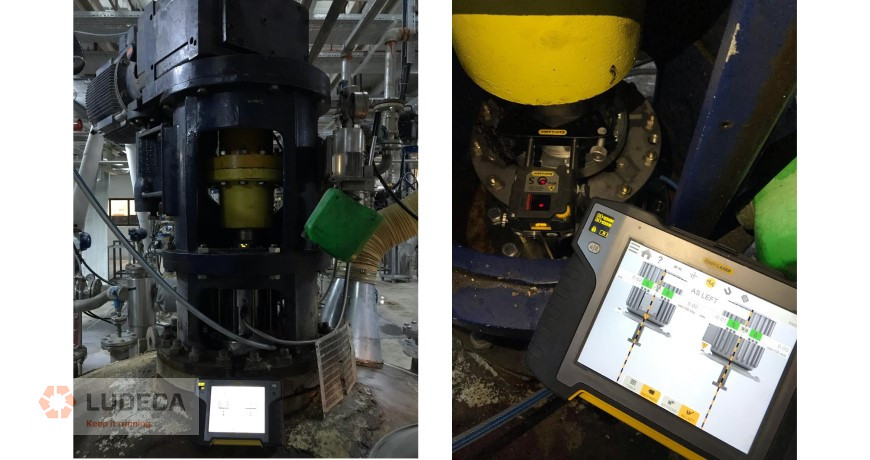

The alignment of the motor shaft to the pump housing shaft needed to be inspected, and if necessary, corrected. The Easy-laser XT laser alignment system was chosen for this task. The compact wireless sensor units were installed on both shafts. Wireless is an advantage in this application as there are no cables to get tangled as the shafts are rotated. Once the sets of readings were taken, corrections were made by translating the motor to correct coupling offset and shimming on the motor flange to adjust the shaft angle. These corrections were calculated by the built in vertical alignment program of the XT laser alignment system. The corrections were monitored live with the system.

The results were documented and sent wirelessly via email to the customer. The result was that the alignment defects of the asset were identified, removed and documented in a short time.

Related Blog: How to Determine a Vertical Pump’s Natural Frequency

Filed under:

Alignment by Diana Pereda