A vibration analyst is constantly viewing data and seeking to identify indications of sub-optimal physical properties indicated by specific vibratory behavior. Most complex systems (if vibration analysis is allowed to be called a system) can be broken down into simpler sub-systems. Some of us, this blogger included, benefit greatly from such simplification in the vibration analysis process. This blog is about one such simplification which may be a helpful addition to the reader’s set of vibratory behavioral pattern recognitions.

As an analyst progresses in the field of vibration analysis, they will come to appreciate the phase property of vibratory behavior. Phase is used most often to look for defects by comparing it across couplings, from top to bottom, or end to end of structures, machines, or machine trains, etc. Here, the author would like to offer a more simplified way to use phase than is often taught or talked about, at least by those who work mostly with anti-friction bearing machines.

Phase in a single bearing:

Let’s approach phase in its simplest form: a single shaft in a single rolling element bearing. A perfect shaft in a perfect bearing, with everything done perfectly; no unbalance, no misalignment, no defects, will have zero relative phase difference between V(ertical) and H(orizontal). In fact, it will not vibrate at all. Because perfection does not exist, we don’t need to worry about running into it.

The machines you will run into will vibrate and the vibration will have phase. The phase of vibration measured at a single bearing will be caused by the imperfections acting on that bearing/shaft assembly. Consider the most common “near perfection” you will likely encounter in the day-to-day life of a condition monitoring technician. This near perfection machine has been aligned well enough for misalignment to contribute virtually nothing to the vibration signal, no bearing defect vibration, only the slightest rotational frequency vibration presumably contributed by a miniscule amount of residual unbalance.

The phase at rotational frequency on this machine will have an almost perfectly circular orbit and show an almost perfectly predictable 90° relationship between H and V. Now consider, if the unbalance increases, without any contribution from other defects, this 90° phase relationship will become even more stark, because the amplitude will increase making the phase reading more stable.

What about misalignment?

If misalignment were introduced into our “near perfect” machine, the orbit of the shaft in the bearing would almost certainly lose its circular motion and take on a herky-jerky motion characteristic, because now the shaft is prevented from the motion that unbalance induces on the shaft, by the restraint imposed by the misaligned bearings. The fact is that the perpendicular phase will now tend toward being either 0° or 180°. Just like the 90°-phase relationship which gets more pure as unbalance severity increases, the 0° or 180° phase relationship is likely to become more pure with an increase in misalignment severity.

How can the phase relationship at two perpendicular bearing points on rotating equipment be 0?

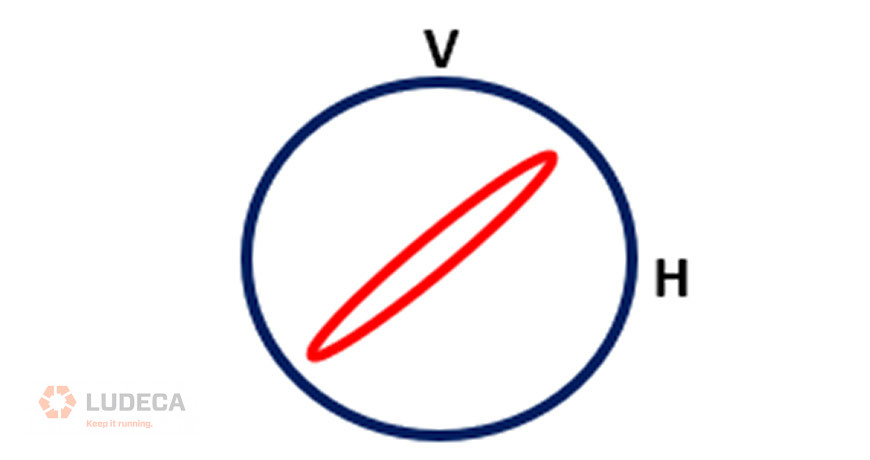

One might wonder how the phase difference could be zero at two perpendicular points. In this case, it helps to visualize the orbit of the misalignment-restricted shaft within the bearing. In the bearing orbit shown in figure 1, the amplitude at rotational frequency recorded on the V sensor and that of the H sensor are maximum at virtually the same instant.

Cautions:

There are other less common possible causes of the vibratory behavior of the very elongated orbit, such as resonance. A simple way to rule out resonance when possible, is to change the rotational frequency by 15% and then make a new observation. A cocked bearing would be an even more unlikely suspect if shaft misalignment is ruled out.

Download our 4 Stages Bearing Failures infographic for a basic reference guide to understanding the stages of bearing failures.

Filed under:

Vibration Analysis by Gary James CRL