Importance of Setting up Alarms and Baselines in Machinery Vibration Analysis

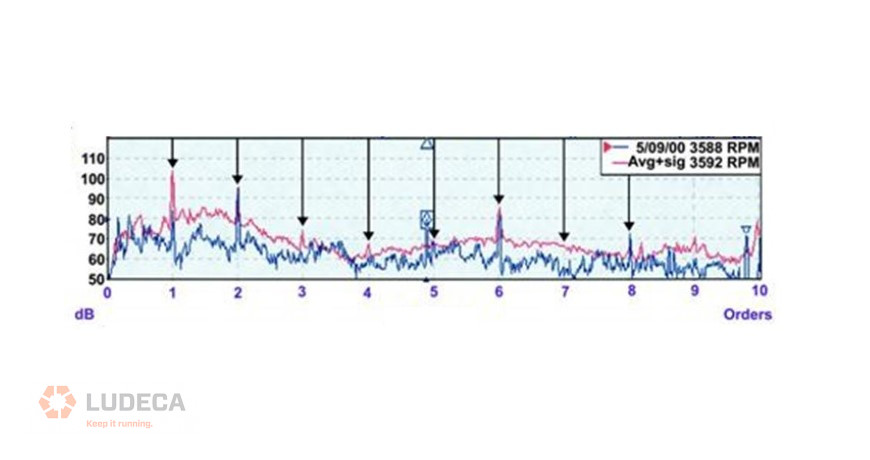

Machinery vibration analysis is an essential tool for monitoring the health of industrial equipment. It involves measuring the vibration of machines and analyzing the data to identify potential issues. One of the critical aspects of vibration analysis is setting up alarms and baselines to detect abnormal machine behavior. Alarms and baselines act as reference points for measuring machine vibration. They help identify when the machine is operating normally and when there is a problem. Baselines are established by measuring the vibration of a machine when it is in good condition. The vibration levels recorded are used as a reference point for future measurements.

Alarms are set up to notify maintenance personnel when the vibration levels exceed a predefined threshold. The threshold levels are typically set based on industry standards, manufacturer recommendations, or the specific needs of the organization. By setting up alarms, maintenance personnel can take corrective action before the machine fails, reducing downtime and repair costs.

In addition to detecting problems, alarms and baselines are also essential for trending data. Trending data involves tracking the vibration levels of a machine over time. By comparing the current vibration levels to the established baseline, maintenance personnel can identify trends that indicate changes in machine behavior. This information can be used to predict when a machine is likely to fail, allowing for proactive maintenance.

In summary, setting up alarms and baselines is critical for effective machinery vibration analysis. They provide reference points for measuring machine vibration, help detect abnormal behavior, and are essential for trending data. By using this information, maintenance personnel can take proactive steps to prevent machine failures, reducing downtime and repair costs.

Testing Machines Under Repeatable Conditions for Machinery Vibration Analysis

Testing machines under repeatable conditions is another critical aspect of machinery vibration analysis. To obtain accurate and reliable data, machines must be tested under controlled conditions that can be repeated. This ensures that the vibration measurements are consistent and can be compared over time. When testing machines, it is essential to consider factors such as load, speed, and operating conditions. These factors can significantly impact the vibration levels of a machine. By testing machines under the same conditions, maintenance personnel can identify changes in vibration levels that may indicate a problem. Repeatable testing also helps establish baselines and set up alarms. By measuring the vibration of a machine under controlled conditions, maintenance personnel can establish a baseline for future measurements. This baseline can be used to set up alarms to detect abnormal machine behavior.

Furthermore, repeatable testing can help validate the effectiveness of maintenance activities. By measuring the vibration levels of a machine before and after maintenance activities, maintenance personnel can determine if the activities were successful in reducing vibration levels.

In conclusion, testing machines under repeatable conditions is critical for accurate and reliable machinery vibration analysis. It ensures that vibration measurements are consistent and can be compared over time. This information can be used to establish baselines, set up alarms, and validate the effectiveness of maintenance activities. By using this information, maintenance personnel can take proactive steps to prevent machine failures, reducing downtime and repair costs.

WANT TO LEARN MORE?

Alan Friedman dba Zenco offers machinery vibration analysis courses and certification in accordance with ISO 18436-2. You can see the live course schedule here: www.ZencoVibrations.com/events. You can connect with him on Linkedin. In addition to public classroom training and public virtual courses, Alan is also available for private courses virtually or on-site in addition to informal training and mentoring. Category I and II vibration are also available in Spanish.

Alan, aka the Vibe Guru, has over 30 years of vibration analysis experience, He has trained thousands of students around the world up to Category IV. One of the things that makes Alan a great teacher is his ability to teach people where they are at. Whether you are a math-challenged millwright, an engineer, or a PhD, Alan will challenge you without overwhelming you. If you are interested in condition monitoring you can also check out his book: Audit It. Improve It! Getting the Most from your Vibration Monitoring Program or hire him for an on-site program audit.

Did you know that Alan Friedman left Mobius and is now providing his own courses?

Filed under:

Vibration Analysis by Diana Pereda