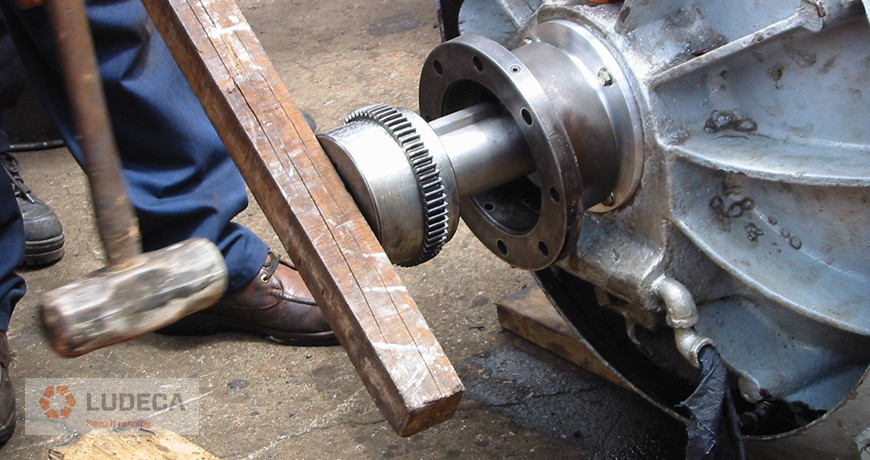

It seems that every maintenance department has at least one Hercules that uses more muscle than technique to complete maintenance activities. Brute force and strength are occasionally required to complete a task. Having Hercules around is important when those moments arise.

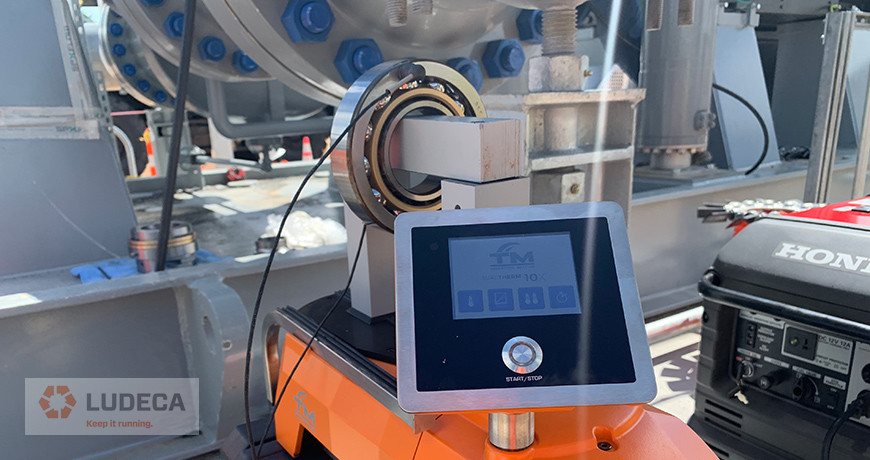

However, applying care and good technique are usually better. Over 90% of rotating equipment has defects at startup that result in equipment failure. One of the reasons arises from making bearing installation a herculean task and not using proper technique. Excessive force applied during bearing installation can introduce defects that lead to premature equipment failure. Instead of beating the bearing on with a sledgehammer, gently heat it up on an induction heater, automatically demagnetize it, and then slip it on. If Hercules did the job, then the bearing and equipment are doomed to failure from the moment of startup. This results in increased maintenance costs, increased risks, and increased equipment downtime.

Installing equipment bearings should not be a herculean task. Instead, proper technique and best practice should be applied to correctly install bearings. Induction bearing heaters like SURETHERM can help eliminate induced bearing defects due to poor fitting and improper mounting techniques. Induction bearing heaters provide increased safety, increased efficiency and reduce the risk of bearing contamination and damage that can result from using brute strength, oil baths, blowtorches, or other improper methods to heat bearings for proper installation.

Related Blog: Induction Heating vs. Conventional Methods to Properly Mount Bearings and other Workpieces

Filed under:

Induction Heating by Trent Phillips