We previously discussed in this series, Do we really need Oil Analysis if We’re Performing other CM Techniques? – Part 2. In this follow-up blog, we will discuss selecting the best CM technique for your equipment.

Part 3 – Selecting the best CM technique for your equipment

We’ve made it to the final installment of this trilogy! Let’s do a quick recap of what we’ve learned thus far. In Part 1, we spoke all about understanding the consistency of oil sampling and determining the criticality of your assets. Next, in Part 2, we really found out more about reading the actual oil analysis report and understanding what the numbers actually mean. We talk about the standard types of tests in addition to some of the specialty tests that can be done for turbines when determining if varnish is present. Let’s take a deeper dive into ways of selecting the best condition monitoring technique for your equipment.

The P-F curve

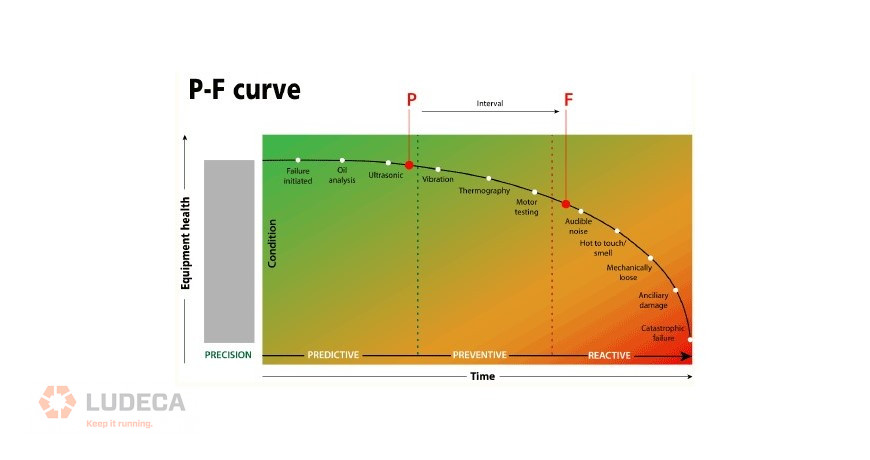

If you work within the reliability sector or even within maintenance, you will be familiar with the P-F curve. This curve is used to represent the way in which an asset can fail. It can be adapted to any asset but users must acknowledge that not every asset will follow this curve exactly. This curve can be used as a guide to charting the progression of asset failures. According to the ISA (International Society of Automation), the P-F curve demonstrates the technologies used to detect failure from the earliest to the latest as per below:

1. Oil Analysis

2. Ultrasound

3. Vibration

4. Thermography

5. Motor Testing

6. Physical Inspection

As seen in the figure above, Oil analysis is the first detection point once a failure has been initiated. However, this should not be the only CM technique used as there are quite a number of factors that contribute to the validity of the data from an oil sample.

Other CM techniques

Since we’ve discussed oil analysis at length (in Parts 1 & 2 of this trilogy), we now need to ask the underlying question, “Do we need other CM techniques if Oil Analysis is already being conducted?”. The simple answer is, yes. While oil analysis may be positioned as the first indicator of an abnormality within a system, there are times when oil analysis results can be misrepresented. If a representative sample is not taken, mislabeled, or not shipped off to the lab in time, then the results can be skewed. This can cause users to miss the window of maintenance or perform misguided maintenance leading to the occurring issue not being solved.

As per the P-F curve, there are a few types of technologies that can be employed to detect the onset of an asset failure before it affects its functionality. These are namely, Ultrasonic, Vibration, or Thermography, all of which LUDECA can provide. The key to any successful CM program is firstly establishing its requirements and then modeling the program based on these. If the main requirement is to detect impending failures on critical gearboxes then the CM program should be designed to capture the information, feed this back to the operators and maintenance department in a timely manner and have the issue resolved before its functional failure.

One way of determining complementary technologies is to evaluate the strengths and weaknesses of each type of CM technology. With Oil analysis, we can only detect the presence (or absence) of materials that come into contact with the oil. This will not include other parts of the machine which may not be lubricated. For these parts, perhaps another type of technology can be employed, so the entire asset is monitored, not just the lubricated parts. Additionally, what if there are no lubricated parts? Then, we can’t use oil analysis as a CM technique!

Selecting the best CM technique

When selecting the best CM techniques for your plant, you can look at:

1. Application of the technique across most of the assets – if a technique is being applied, we have to make sure it is scalable. It may not make much sense if we’re only applying the technique to one asset and have to either buy the equipment or get in-house personnel certified to use it. If technicians will be trained in using the technique, then it should be integrated across the assets to bring more value.

2. Integration of these CM techniques into the PM programs – most technicians are not very fond of having another task added to their routine. However, by showing technicians the value that these techniques bring and the possibility of reducing their future workload.

3. Frequency of application – depending on how often the technique will be used, then a decision can be made on whether the company should invest in the actual CM equipment and have in-house personnel trained or if it makes more sense to have a third party perform the inspections. The ROI on the investment into the CM technology should be weighed before making such a decision.

Essentially, while oil analysis is a great predictive method of detecting failures it should be complemented with other CM techniques. This allows us to get the full picture of what is occurring throughout the equipment. Users should select the CM techniques which are best suited for their plant or facility as per their requirements. Ideally, users should consider all of the options before selecting the best-suited CM technique.

Thank you Sanya Mathura with Strategic Reliability Solutions Ltd for sharing this informative and educational article with us!

Related Blog: One Condition Monitoring Technology is Not Enough!

Filed under:

Condition Monitoring by Diana Pereda