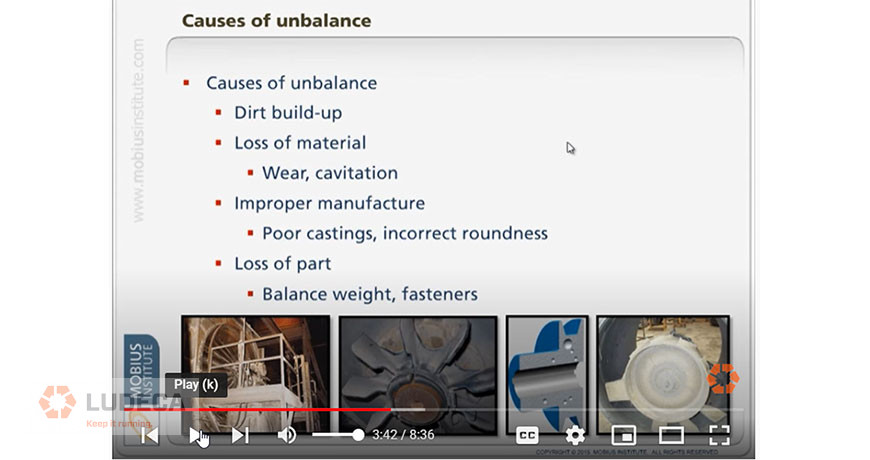

Unbalance can be caused by many possibilities such as listed below but not limited to just this list. Possible sources could be many more than those listed. Generally, if the rotor is dirty, clean it, as this alone may correct any unbalance. If it has damage fix it; if it’s loose tighten it, if a fit is not correct then correct it, etc.

- Machining tolerances and fits allowing assembly error.

- Improper fits of components on shafts

- Eccentric components

- Part bored off center

- Incorrect assembly

- Improper keyway length

- Voids in castings

- High porosity in the casting

- Wear and corrosion

- Abrasive material being moved

- Thermal or mechanical distortion

- Equipment improperly stress-relieved or heat treated

- Foreign matter

- The material being moved has a high adhesive factor and it sticks to the rotating mass until it reaches a point where it begins to come off

- Structural damage such as bent or broken components

- Something in the system has broken and traveled through the rotating element and caused damage

- Loose parts

- A component has loosened up or was improperly tightened originally.

Filed under:

Balancing by Gary James CRL