Unbalance occurs when a rotor’s center of rotation does not correspond with the center of the rotational mass. Simply stated, there is a “heavy spot” on the rotating element.

Mass is seldom evenly distributed throughout a rotor. Equal distribution of mass is not required for the rotor to be “balanced.” However, the mass variations should be distributed about the center of rotation so that the resulting centrifugal forces serve to counteract each other.

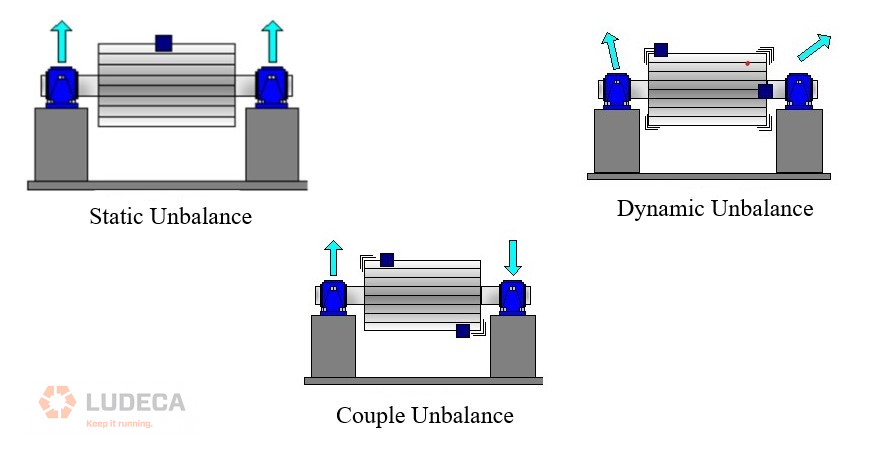

There are three types of unbalance:

- Static unbalance – The rotor has a single heavy spot that will “fall to the bottom” if the bearings have low friction.

- Couple unbalance – The rotor has two equal heavy spots located 180 degrees from each other on opposite ends of the rotor.

- Dynamic unbalance – The rotor is wide relative to the diameter and has two equal or unequal heavy spots, one on the drive end and one on the non-drive end, at different locations relative to each other, and not at 180 degrees opposite.

Download our 5-Step Balancing Procedure a simple and effective procedure for doing field balancing. Pair it with our advanced VIBWORKS Balancer to help you identify, correct and avoid the unwanted consequences of equipment unbalance!

Related Blog: 8 Keys to a Good Balancing Job

Filed under:

Balancing by Gary James CRL