Bearings vs. Lubricants_ Regreasing

Commenting to Ana Maria Delgado CRL with LUDECA, about the bearings and the lubricants that keep them operating, it occurs to me to write about a point of view that few people observe.

Commenting to Ana Maria Delgado CRL with LUDECA, about the bearings and the lubricants that keep them operating, it occurs to me to write about a point of view that few people observe.

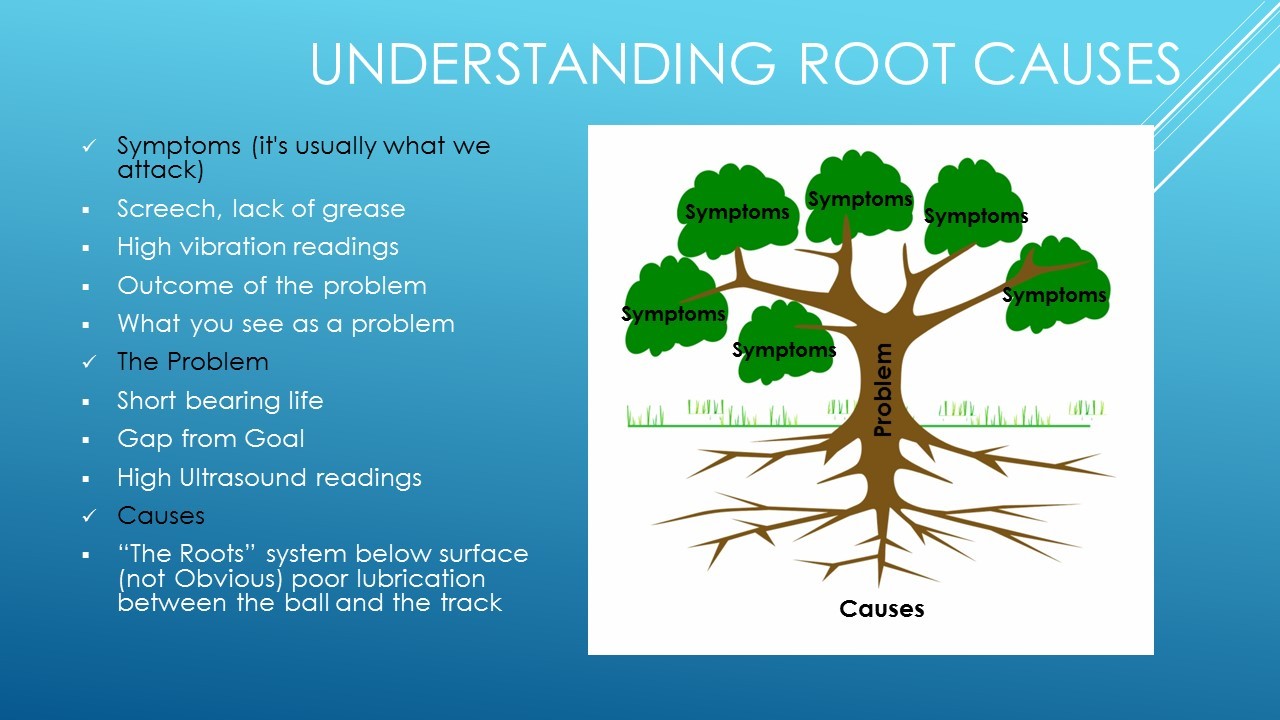

When we talk about lubricants, and regularly when referring to bearings, we talk about grease. Where the grease really performs its work, is at the point of contact of the ball or roller and the inner or outer race. The rest of the grease in the bearing housing does not perform lubricant work. The problems begin when we have to re-grease it, the regreasing of bearings is very particular, the type of grease, the correct amount, at the right time. This is something we hear in lubrication training, particularly on the way to World Class Lubrication. However, when you know the tools of Lean Six Sigma, you are always looking for the True Root Cause.

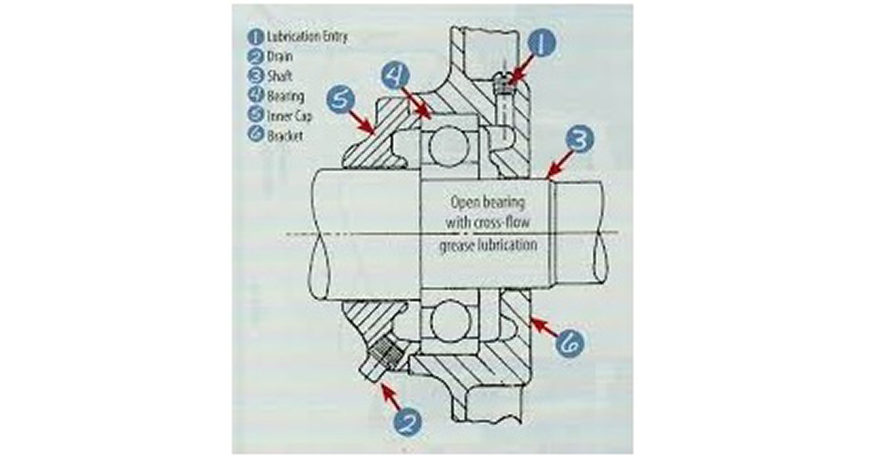

But at some point we have thought about the bearing housing, where the grease enters the housing, what is the route to the bearing, and more importantly where the grease residues damaged by time and temperature leave, not counting current discharges in the case of electric motors. In that passage, it is important that the grease that enters displaces the grease inside the cavity, that the grease that enters pushes the grease that is between the ball and the track, thereby relieving the bearing load. Not being less important that the grease that has finished its useful life goes outside, it does not lead to the winding in the case of electric motors.

If we stop to think about the cavities of the bearings, there are many readings about it, but a writing from Heinz P. Bloch P.E. comes to mind, for a Pump Symposium in 2015, “Lubrication Delivery Advances For Pumps and Motors Drivers”, One of the best writings on the topic of bearing lubrication, thanks to H. P. Bloch, I recommend you read it. This paper puts you to think about the importance of the passage of grease through the bearing and how it has to be allowed to evacuate the grease that has ended its useful life inside the bearing housing.

Of all types of bearing housing, only the one that allows cross-flow of grease when lubricating is ideal. When add grease to a bearing the grease under hydraulic pressure of the gun will move through all possible cavities, but if we give a relief on the opposite face of the bearing where the grease entry is, then it will do its job, to remove the spent grease and accommodate the new grease between the ball and the inner and outer race, extending the useful life of the bearing, avoiding maintenance interventions, improving productivity.

Reading the letter of Mr. Heinz P. Bloch, reminds of an old friend his beginnings in the industry, when he just graduated from college, he was in probation and have to go through the different facets of Manufacturing, and then Maintenance, he had to work directly with an industrial mechanic, who did not like to teach, therefore he had to learn by looking, without asking questions, he forced it, “which he thank him ”, to look at all the details in the mechanical assets, how many threads the screws have, the size of the pipe, if the bearings were balls or rollers, where the grease enters the bearings in the electrical motors, the right tool for the job, etc.

He forced him to speak the language of the bearings, to touch them carefully and capture the operating temperature, to make contact with the nail and appreciate the vibration, to listen and smell the condition of a rotating asset, it is interesting.

The grease has to come into contact with the ball and the track, if the Bearing Housing does not allow the new grease to displace the old grease and come into contact with the ball and the track, the bearing will fail, it will be long term but the fatality will occur, or you will have unwanted mechanical interventions of rotating assets. The training of technicians who perform the lubrication task is very important, for them to understand this.

Filed under:

Articles and Case Studies, Lubrication by Diana Pereda

Thank you Juan R Márquez with Eli Lilly and Company for sharing this informative article on bearing lubrication with us!

Download our Oil & Grease Storage Best Practices which includes helpful tips to outline the best practices for proper lubrication storage.

Related Blog: How to Grease Your Bearings Using Ultrasound?