We previously discussed misaligned couplings and how to reduce failures when ultrasound and alignment meet in “Ultrasound and Alignment Meet at the Coupling to Reduce Failures.” In this follow-up blog, we will discuss how ultrasound and alignment come together to improve belt-driven performance.

Misalignment in belt-driven equipment is one of the leading causes of failures throughout the industry. It breaks down machines and often costs your company thousands upon thousands of dollars in repair expenses and unplanned downtime. Imagine if you could combine two technologies you may already be using to prevent some of these failures. Ultrasound and precision laser alignment will make your maintenance department ever more proactive than ever before.

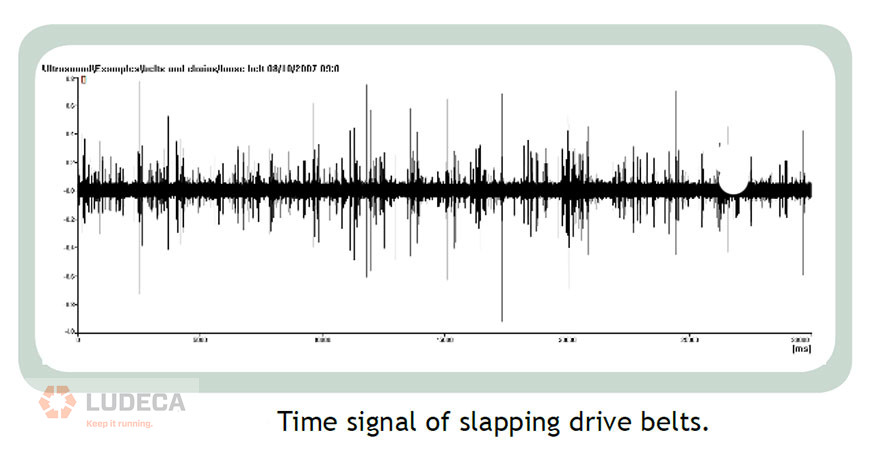

Belts can be too loose, too tight, or be running on misaligned pulleys. Loose belts will slap and produce a noise similar to whiplash. Tight belts and misaligned belts will generate additional friction which will again be audible ultrasonically. Figure 1 is a sample time signal of slapping belts.

An easy way to detect and prevent failures is to add your belt driven machines to your ultrasound routes. It will require a few extra measurements on each route and some trending. However, the benefits will far outweigh the costs. By being able to tell when a belt system needs to be aligned and properly tensioned before it breaks down, we can be more proactive and less reactive.

Once the imminent failure is being detected, we can address it with a realignment of the belt drive unit using our Easy-Laser XT190 pulley alignment system. It is easy to use and it will provide the user with a PDF report for documentation and accountability.

This blog was inspired by Uptime Magazine’s article, “There’s Something in the Air”, July 2009, pp. 48-53, written by Thomas J Murphy with SDT Ultrasound Solutions.

Download our 5-Step Sheave Pulley Alignment Procedure which provides a simple and effective procedure for sheave pulley alignment of belt-driven equipment.

Filed under:

Alignment, Ultrasound by Carlos Bienes CRL