We previously discussed a lack of repeatability and identified some of the most common and easy-to-correct culprits in Laser Shaft Alignment Troubleshooting: Part 1 Repeatability. In this follow-up blog, we will discuss Response to Corrections.

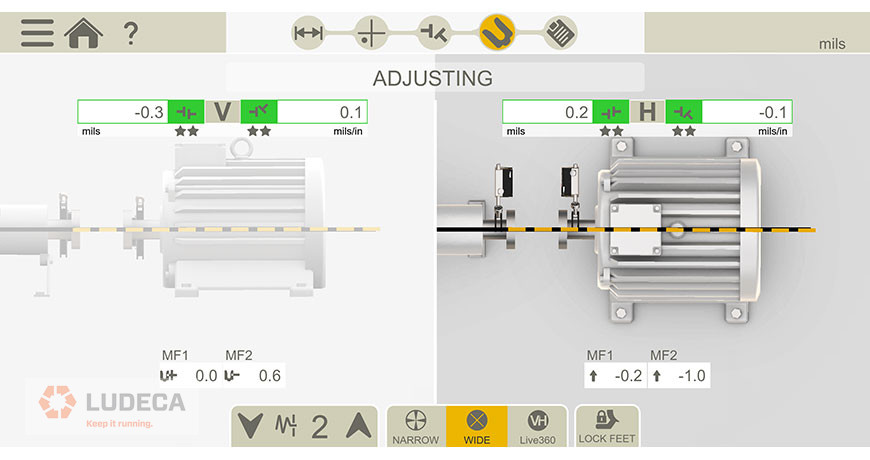

Along with measurement repeatability, the laser alignment system’s ability to display the correct moves to bring the machines into alignment is crucial. If the machines do not respond to these corrections, you’ll be chasing moves throughout the alignment process – which isn’t fun!

WHAT IS RESPONSE TO CORRECTIONS?

Response to corrections is how the moves given by the alignment system work out.

If the results don’t reflect the moves made, the following can be the causes:

- Incorrect dimensions entered for the machinery. The alignment system relies on the correct dimensions being entered in order to predict the correct move amounts.

- Coupling strain can cause small deflections in the machine shafts that can misreport the correct shaft centerlines to the alignment system. Precise measurements of the rotational centerlines is crucial in determining the misalignment between them.

- Soft foot amongst other negative effects can hinder adjustment attempts.

In addition to the above considerations, environmental vibration, external stresses on the machines, and thermal effects can cause a lack of response to corrections. Identifying and accounting for these causes will make your alignment easier overall and help you get it done faster.

Watch our Shaft Alignment Know-How: Thermal Growth video to learn the importance of accounting for thermal growth on rotating equipment.

Filed under:

Alignment by Oliver Gibbs CRL