What is repeatability?

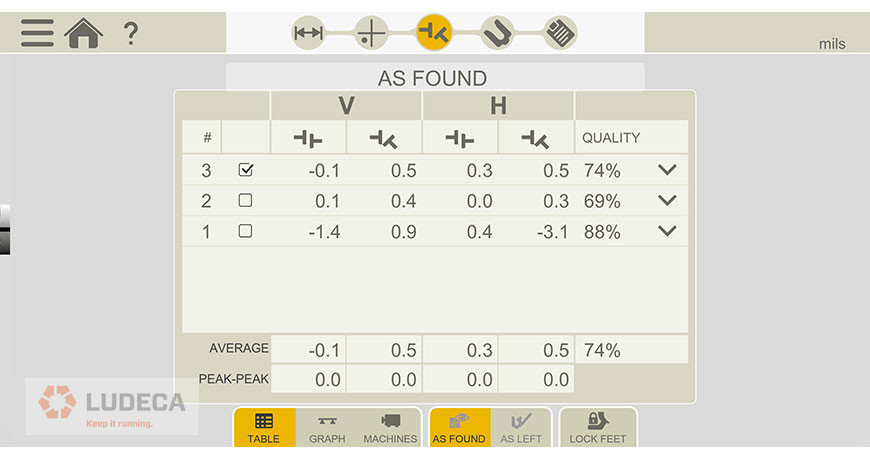

Repeatability is the consistency of measurement results between consecutive sets of readings.

Laser alignment systems are capable of producing highly repeatable and reproducible measurements with just a few components attached to rotating machinery. When troubleshooting the cause(s) of lack of repeatability, it is helpful to try to identify some of the most common and easy-to-correct culprits.

Having a lack of repeatability can be caused by:

- Loose components such as measurement units or brackets. These components should be affixed to the shafts and should be tightened to prevent slipping or rocking of any kind.

- The measurement unit assembly should not rub on or strike any stationary component during a sweep measurement.

- Backlash effects due to play in the coupling should be minimized.

- If measuring using a sweep function, care must be taken to keep the rotation going in only one direction during measurement. Never let the heads rotate in the opposite direction.

- Use the appropriate measurement mode for the machines: i.e. sweep, multipoint, 9-12-3, etc.

Establishing repeatability of the alignment system is one of the most important steps in shaft alignment. It can make the difference between an easy-to-accomplish job or a job where you’re chasing your corrections.

Watch our Shaft Alignment Know-How: Repeatability video and learn more about the importance of achieving repeatability of measurements before making alignment corrections.

Filed under:

Alignment by Oliver Gibbs CRL