Our colleges at Benchmark PDM recently had a request from a customer to do some pump alignment. When we normally think about pump alignment, we usually think of shaft to shaft alignment. In this case, they wanted bore alignment. They were installing a brand-new pump and when they rotated the shaft, they could hear grinding.

After further inspection one of the techs could see that the bearing housing had been moved – either during shipment or when it was stored. They could see that the dowel pin had been damaged.

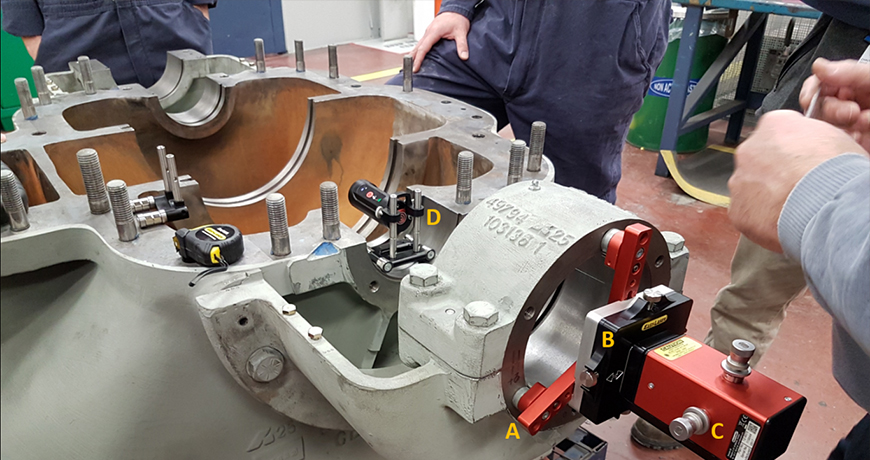

Figure 1

If you pop the lid off this style of pump (See Figure 1 – photo courtesy of KSB Pumps Canada), we see the shaft and the center mounted impeller. On each side of the impeller we have the wear rings, which sit in the bores. Outside of that we have two stuffing boxes or seal bores and outside of these we have the bearing Journals which are also bores. All of these bore centers need to be colinear, meaning in a straight line.

The old traditional methods for doing this type of work was done using piano wire or a mandrel. They would use the stuffing box or the wearing bores as reference points then measure to see if the bearing bores where in alignment. This method was “hit and miss” because its so difficult to set up and measure in this way. It also took a very long time.

Bore Alignment with Lasers

Using a laser-based measurement system has significantly reduced the time taken to do bore alignment. More importantly, it has improved the accuracy significantly. There are now automatic reports that go with the final bore alignment that has been completed – a documented history of the work is very important.

Figure 2

There are many different applications where bore alignment is done using lasers. For example, extruder barrels that need to be aligned to a gearbox in the plastic industry, crankshaft bearing journal bores in diesel/natural gas engines or compressors in the oil & gas and energy industries and stern tube alignment in the shipping industry. These are just three examples that show how varied the type of alignment work is.

Click here to read the entire case study “Bore Alignment on a Split-Casing Pump”

Filed under:

Alignment, Articles and Case Studies by Diana Pereda