A customer with a need to monitor machinery remotely and limited to a small budget invested in the VIBCONNECT® RF system to keep their machines running. During a routine check of the data, it was noticed that a certain machine was in alarm. The OMNITREND® software easily identified the machine that was in alarm by the red indicator (see Fig. 1).

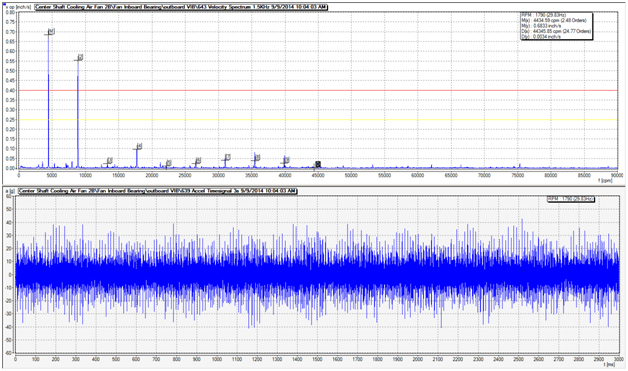

The customer contacted LUDECA to assist in analyzing the issue. The frequency did not match any of the components given for this machine. The waveform data showed extremely high levels of vibration and indicated that something was seriously wrong with this machine (see Fig. 2).

It was suggested that the machine be visually inspected for any abnormalities, including a strobe for the visual inspection. The strobe was locked into the known frequencies that were showing in alarm. The customer was able to identify that a broken belt was the cause of the high vibration levels (see Fig. 3).

New belts were installed and the pulleys were properly aligned using the DotLine Laser pulley alignment tool to prevent future belt failures due to misaligned pulleys.

Filed under:

Alignment, Condition Monitoring by Mickey Harp CRL