Soft Foot has often been noted as the most inexact science part of the shaft alignment job. Historically, when people think of Soft Foot, they often want to neglect, ignore, or otherwise do everything possible to not deal with it. This is one of the traps that leads down the path of bad habits, bad alignments, and more problems down the line.

Shaft alignment can be thought of as two things:

- Aligning the shaft centerlines of rotation

- Checking for and correcting Soft Foot

Soft Foot, in fact, plays so much of a role in shaft alignment, that if one were to analyze the 5-Step Alignment Procedure below, one can see that Soft Foot appears in 2 out of the 5 steps. Therefore, Soft Foot can be thought of as almost half the alignment job.

5-step Alignment Procedure:

- Pre-alignment checks – including inspection and cleaning of machine supports

- Rough alignment – “eyeball clean” (with bolts loose) and Rough soft foot Loosen all bolts and “fill any obvious gaps”.

- Initial alignment – Get to within 5 to 15 mils at coupling or less than 20 mils at feet.

- Final soft foot – All feet less than 2.0

- Final alignment to tolerances and documentation

What is Soft Foot? Soft Foot is Machine Frame Distortion.

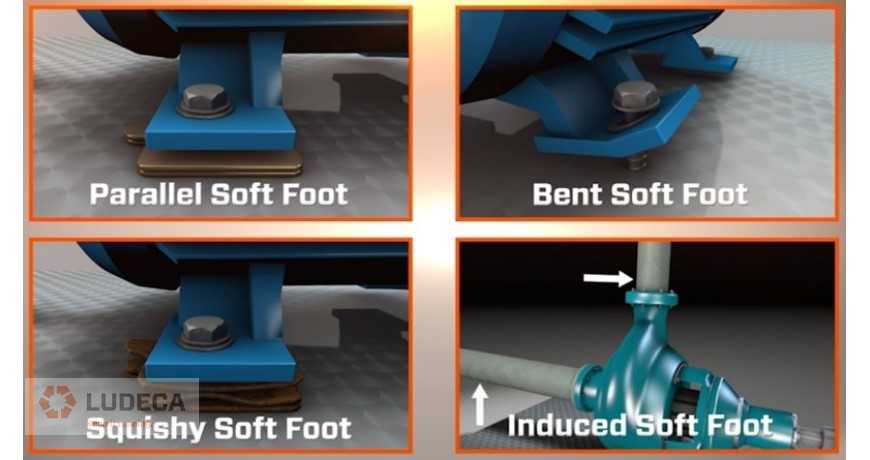

How does it happen? Soft Foot can happen from several things, including:

- Bent Feet

- Bad Bases (warped, uneven, flimsy)

- Dirt, rust, corrosion under feet

- Excessive or missing shims under the feet

- Pipe stress

- And any combination of the above…

What should be done about it?

A full and extensive diagnosis should be done on every machine foot to determine whether or not the tightening of that particular bolt is causing machine frame distortion, and thereby causing shaft misalignment or machine frame strain.

A few helpful tips to remember are:

- Minimize total number of shims under each machine foot to no more than 4 shims per foot.

- Make sure the area is clean, including machine feet, bases, shim packs, etc.

- Jack bolts should be backed off, so they don’t interfere with the soft foot check.

- When checking for soft foot, only one machine foot should be loosened at a time, and the deflection or movement at the shaft noted.

In conclusion, soft foot plays a big role in machine reliability and therefore should not be ignored. Laser alignment systems such as the Easy Laser XT series can help diagnose and correct soft foot.

Filed under:

Alignment by Carlos Bienes CRL