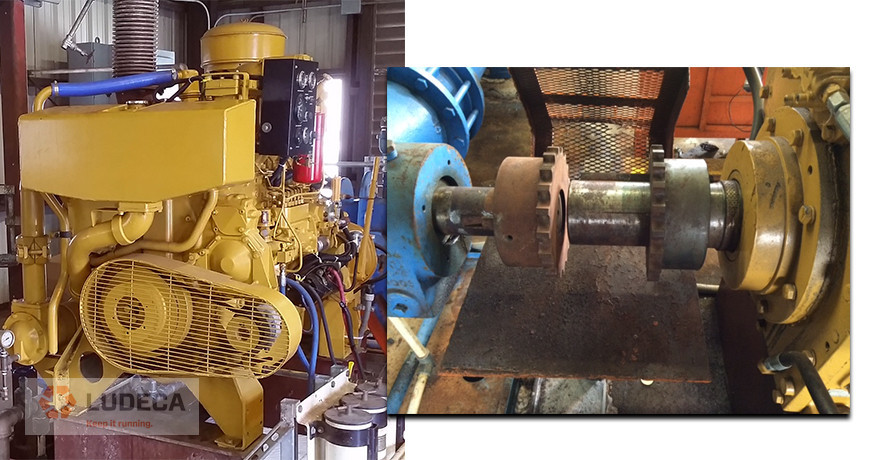

The Problem:

The customer complained of excessive vibration on a wastewater pump driven by a diesel engine. Upon performing an alignment check, the machine shafts were found to be grossly misaligned. Furthermore, proper alignment was found to be impeded by a base-bound condition of the engine combined with external horizontal forces caused by the exhaust stack.

The Solution:

A base-bound situation means a machine must be lowered to bring it into alignment but insufficient shims are present under the feet that must be lowered to permit removing them in order to achieve the alignment correction. Using an Easy-Laser XT770 laser shaft alignment system, it was easy to determine alternative possible corrections to overcome the base-bound condition. Horizontal alignment was also achieved using the graphical display of machine shafts and the live-move mode of the alignment system.

Savings:

Easy-Laser XT770 made it possible to find positive (instead of negative) shim corrections to immediately achieve alignment to within tolerance. This meant that enormous time and expense were saved by not having to disconnect and remove the engine, as well as hire a machinist and portable milling machine to mill down the base-plate of the engine.

Watch our Shaft Alignment Know-How: Bolt-Bound motion graphic video to learn about the options of achieving alignment when in a bolt-bound or base-bound condition.

Filed under:

Alignment by Oliver Gibbs CRL