From a reliability perspective, commissioning a machine requires precision shaft alignment to the correct tolerances and proper documentation. Ideally, these alignments should be performed using a laser system with built-in ANSI alignment tolerances such as the Easy-Laser XT770 and with the ability to generate a detailed graph report of the alignment, both as found and as left. But what if the technician could do a little more than just the shaft alignment, like checking the overall vibration levels of the machine before and after the work? Pre- and post-vibration checks will reassure you and your supervisor or customer that the job was done correctly.

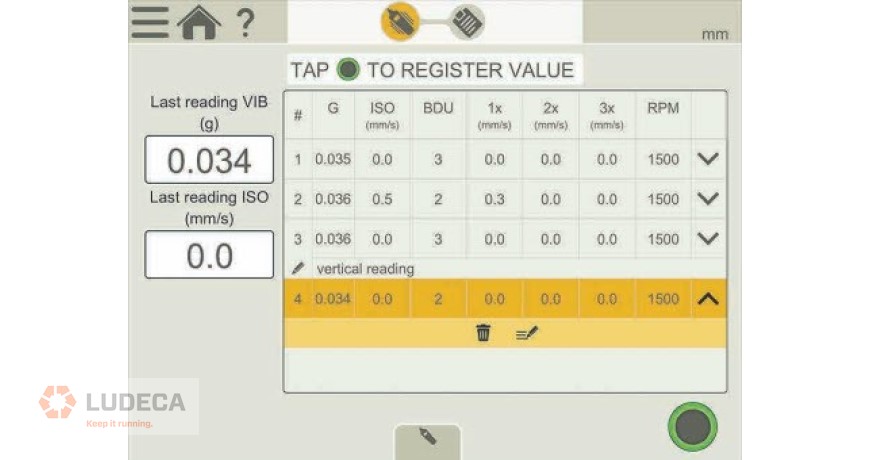

A tool such as the Easy-Laser XT280 makes collecting vibration data from assets like pumps, motors, fans and bearings simple and fast. It displays 1×, 2×, and 3× RPM, total level, as well as bearing condition, providing necessary information for the installation and alignment job.

The XT280 interfaces with all Easy-Laser XT alignment systems but can stand alone if connected to a smartphone or tablet using the Easy-Laser XT Alignment App to generate PDF reports with photos of each measurement point to support acceptance checks after installation and alignment.

Filed under:

Alignment by Carlos Bienes CRL