On a recent plant visit, our solutions provider Bob Dunn with I&E Central, Inc. used the SDT 270 ultrasound instrument and a contact sensor to inspect and capture waveforms on a series of valves on an automated manufacturing machine. The results were a revelation!

On a recent plant visit, our solutions provider Bob Dunn with I&E Central, Inc. used the SDT 270 ultrasound instrument and a contact sensor to inspect and capture waveforms on a series of valves on an automated manufacturing machine. The results were a revelation!

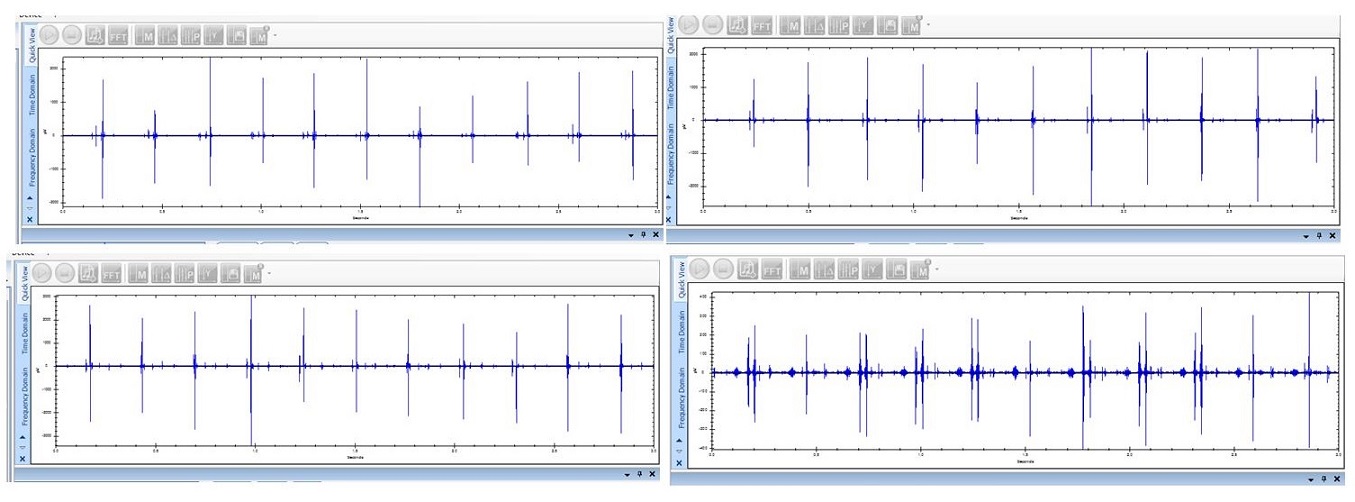

These valves open every 0.25 seconds and pass a brief pulse of air into the process. There were six valves, a 3-second signal was acquired on each. When we viewed the .wav files, one was significantly different from the rest, 4 examples are shown. Valve # 5 was passing a “double” pulse on most of its cycles.

Comparing signatures or levels on like components is a valuable diagnostic approach. At this point, the underlying cause has not been determined, but it is likely a worn component, and the valve should at the least be inspected further and possibly replaced. The failure of one of these valves would stop production on a high-speed automated line.

Properly applied, ultrasound gives you great insight into many types of assets!

Filed under:

Ultrasound by Ana Maria Delgado, CRL