What is the proper technique for performing steam trap inspections? My short answer never changes. It involves two readings…one was taken a few feet upstream of the steam trap to ensure there is flow, and the other reading was taken immediately after the steam trap. If the steam trap is operating correctly, you will hear it cycle. Ultrasonically, this means the signal downstream of the steam trap should be silent, followed by intermittent increases in dBµV levels, indicating a discharge.

By listening to a steam trap cycle this way, ultrasound technicians can determine if the steam trap is cycling properly and functioning as it should. Technicians will also be able to determine any linkage issues the steam trap may be facing.

Over the years, I have found issues with this inspection method. The most glaring issue is that steam traps vary widely in cycle times. This leads to inconsistent and unpredictable inspection times. While this is more of a nuisance than anything else, it still makes inspectors think twice about performing inspections and predictive maintenance interventions on steam traps – especially when considering most steam traps can be replaced for a few hundred dollars.

What Do Unmaintained Steam Traps Cost You?

Is it a waste of time, money, and resources performing condition monitoring and implementing predictive maintenance interventions on an asset with such a low replacement cost?

No! It is not a waste of time, money, or resources. Your steam system and the steam traps that comprise them are designed to deliver clean steam from the boiler rooms to the intended point of use as efficiently as possible. And steam is not a cheap industrial resource to create.

The heat energy required to convert water to steam is measured in British Thermal Units. One BTU raises the temperature of one pound of water, by one degree Fahrenheit. This means when a pound of the steam condenses back to the water, one BTU was wasted.

Your steam system should minimize steam loss, maximize the transfer of heat, and remove condensable and non-condensable gasses that make your steam impure. When the assets that make up your steam system are ignored, your steam systems components degrade, your steam systems efficiency deteriorates, and eventually, your steam system won’t be able to deliver on its engineered purpose.

Failures in your steam system result in lost steam through leaks and lost steam when it condenses back to water vapor, and lesser quality steam reaches its intended point of use. Failures in your steam system also mean more greenhouse emissions as a result of having to produce more steam to compensate for losses. The bottom line, poorly maintained steam systems result in more losses than that just the price of replacing parts.

Safely Inspecting Steam Traps

Before going further, I would first like to point out that steam is a dangerous commodity. Maintenance personnel, factory workers, and condition monitoring technicians need to be aware that steam has both pressure and temperature, not to mention it’s also invisible. When you see what most people call “steam,” it’s actually just water vapor that has cooled down and condensed back to water – and it’s not overly dangerous.

On the other hand, invisible steam leaks are very hot, very dangerous, very high pressure, and very INVISIBLE. They can burn through clothes and melt human flesh. This is why I always strongly recommend technicians go out to monitor steam traps and wear the proper PPE. That means wearing long sleeves, gloves, eye protection, and any other articles of PPE that are mandated for that location of your facility.

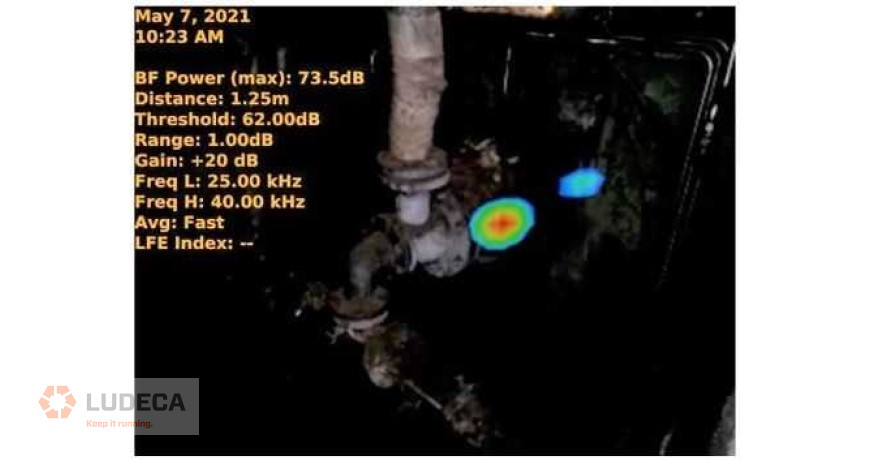

Before I enter an area where there might be live steam leaks, I like to perform an airborne ultrasonic inspection of the area. The best tool for this is the SonaVu™ Acoustic Imaging Camera, as it not only locates steam leaks in your steam system but also visualizes any potential danger on screen.

After performing an airborne ultrasound inspection and confirming there are no dangerous steam leaks, I can proceed with my contact ultrasound inspection on the steam traps I intend to monitor.

Click here to continue reading the entire article, “Best Practices for Inspecting Steam Traps” and learn about the remaining three best practices so you can properly inspect steam traps!

Related Blog: What are SDT Ultrasound Solutions Four Condition Indicators?

Filed under:

Ultrasound by Paul Klimuc CRL - SDT Ultrasound Solutions