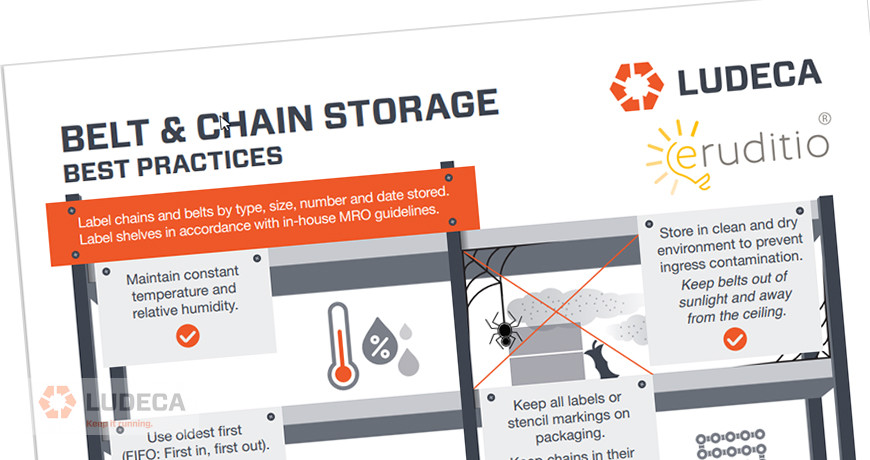

A few simple practices could help to prevent damage to your spare belts and chains:

- Label chains and belts by type, size, number, and date stored. Label shelves in accordance with in-house MRO guidelines.

- Maintain constant temperature and relative humidity. Store in a clean and dry environment to prevent ingress contamination. Keep belts out of sunlight and away from the ceiling.

- Use oldest first (FIFO: First in, first out). For Belts: Validate date of manufacture is within the past 2 years. For Chains: Date of purchase should be added.

- Keep all labels or stencil markings on the packaging. Keep chains in their protective wrappers and packaging until ready to use.

- Tag belts with a “dispose-by” sticker. Set for 5 years after the manufacturing date. Dispose of expired belts annually.

- If not packaged, lubricate chains frequently to prevent corrosion.

- Lay chains and belts on a flat surface (possible damage if hung). Flip periodically. Belts can be hung on a foam-noodle wrapped peg with the same radius as the sheave.

- If not packaged, DO NOT stack.

- Store chains in a vibration-free environment.

Visit our Knowledge Center and download our BELT & CHAIN STORAGE BEST PRACTICES Infographic. Perfect to print and hang in your storeroom!

Thank you to Eruditio LLC for their help with this blog/Infographic!

7 Belt Storage Tips for Better Equipment Performance and Long-Lasting Belt Life

Filed under:

Reliability by Ana Maria Delgado, CRL